A dryer for the production and processing of capacitor shells

A dryer and capacitor technology, applied in the field of capacitors, can solve problems such as capacitor leakage, capacitor leakage, oil leakage, capacitor shell rupture, etc., and achieve the effect of preventing moisture from remaining in the

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

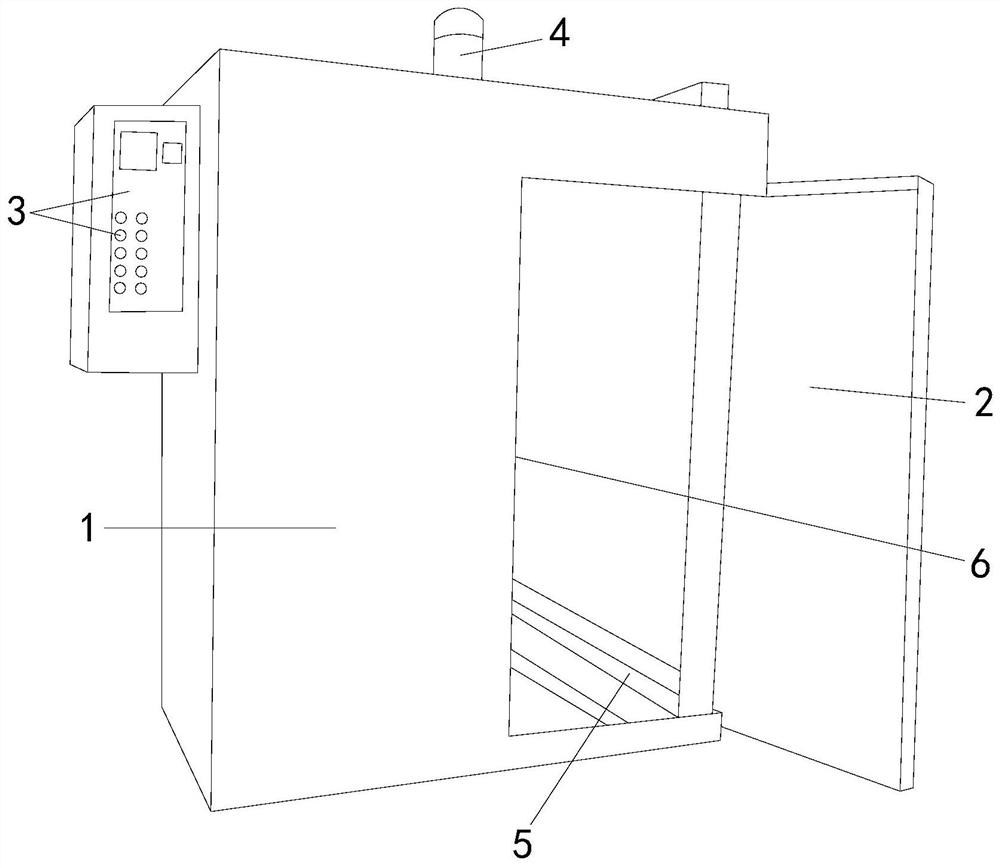

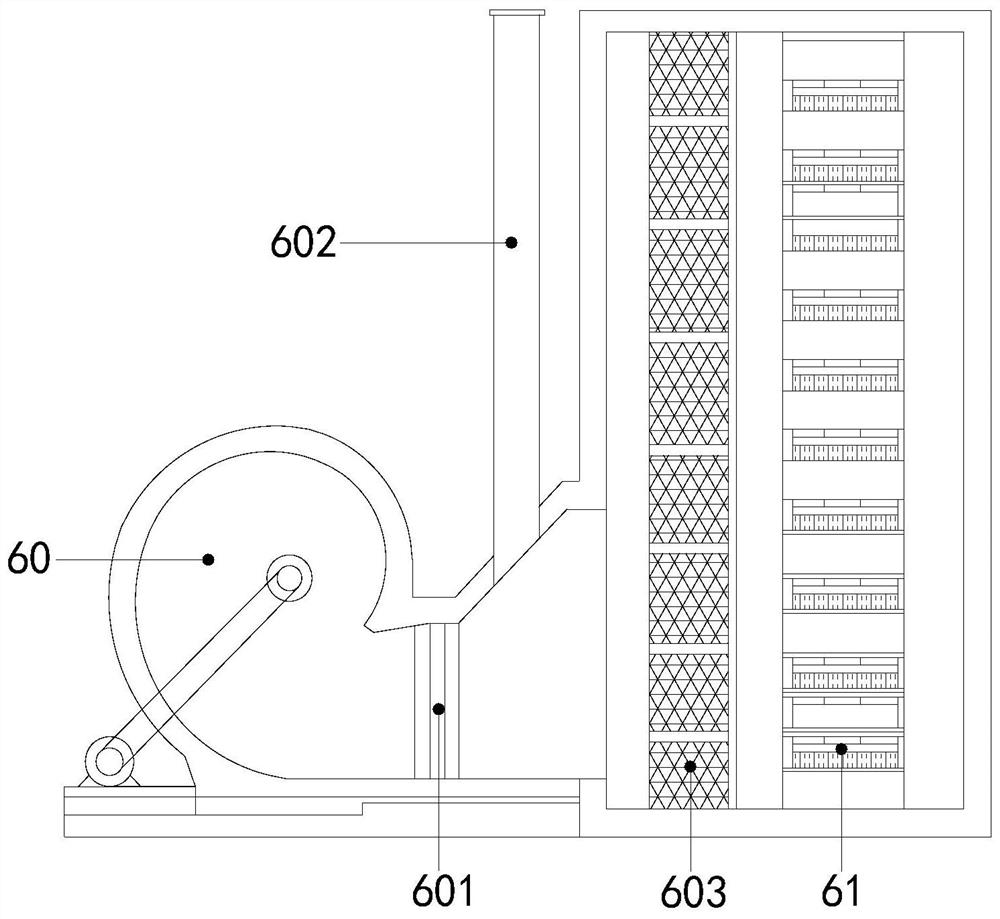

[0023] see figure 1 , the present invention provides a drying machine for the production and processing of capacitor shells, the structure of which includes: a cabinet 1, an insulated box door 2, a controller 3, an exhaust pipe 4, a slide pipe 5, and a drying rack 6. The side of the cabinet 1 is provided with an insulated box door 2 and a controller 3 respectively. The exhaust pipe 4 runs through the cabinet 1. The cabinet 1 is equipped with a slide pipe 5 and a drying rack 6. The cabinet 1 is the main body of the dryer. Its overall appearance is a hollow cuboid, which also includes the shell structure of the equipment. After the insulated box door 2 is closed, it forms a closed space with the chassis 1, which can effectively prevent heat loss, and based on its high-strength insulation made of the same material as the chassis 1 The temperature performance can block most of the heat in the case 1 during the period of time when the case 1 is closed to prevent heat from being tr...

Embodiment 2

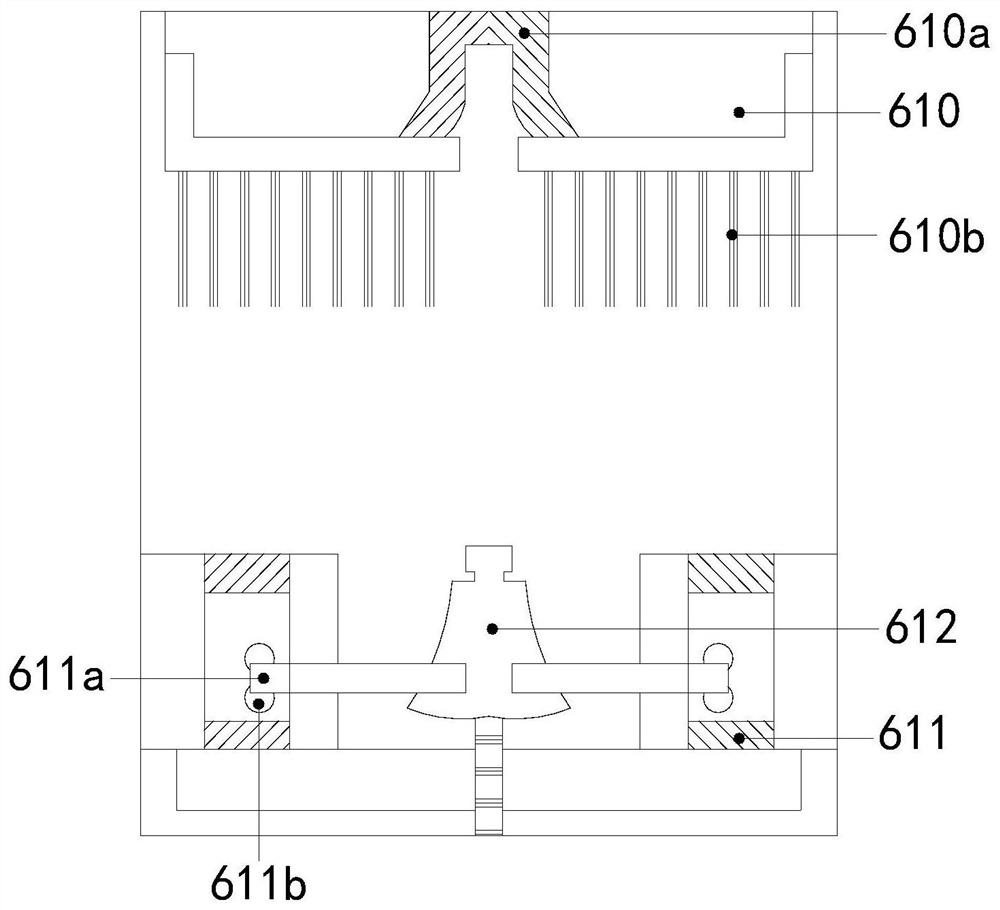

[0029] The description of the second embodiment drawn in conjunction with the first embodiment, combined with image 3 , Figure 4 and Figure 5 , the bottom of the touch-press upper seat 610 is connected to the magnetic sliding lower seat 611 at intervals, and the magnetic sliding lower seat 611 runs through and connects the dehumidification ring 612. The air jet swirl 6120 is located at the bottom of the upward swivel fan 6220 and the two are connected to each other. The side of the turning shaft 622a is annularly provided with an inflatable bag 622b. The surface of the inflatable bag 622b is distributed with a water-absorbing brush 622c and a drainage brush is arranged inside it. 622d, when the equipment is at a relatively stable and constant temperature, lay the capacitor case flat on the drying rack 6, and lift the capacitor case by means of the repulsive magnetic field formed between the touch-press upper seat 610 and the magnetic sliding lower seat 611, and at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com