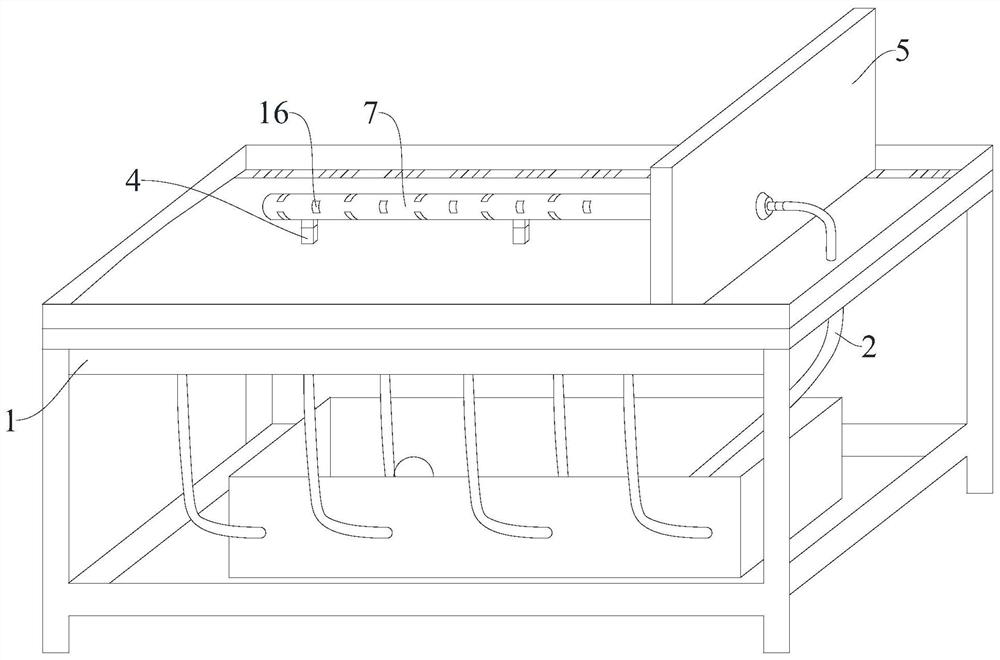

Internal rotation-type cleaning device for sausage casing processing and production

A cleaning device and internal rotation technology, which is applied in the direction of cleaning intestines, etc., can solve the problems of single washing method, poor washing effect, and residual impurities of casings, and achieve the effect of simple and quick disassembly, various washing methods, and improved cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

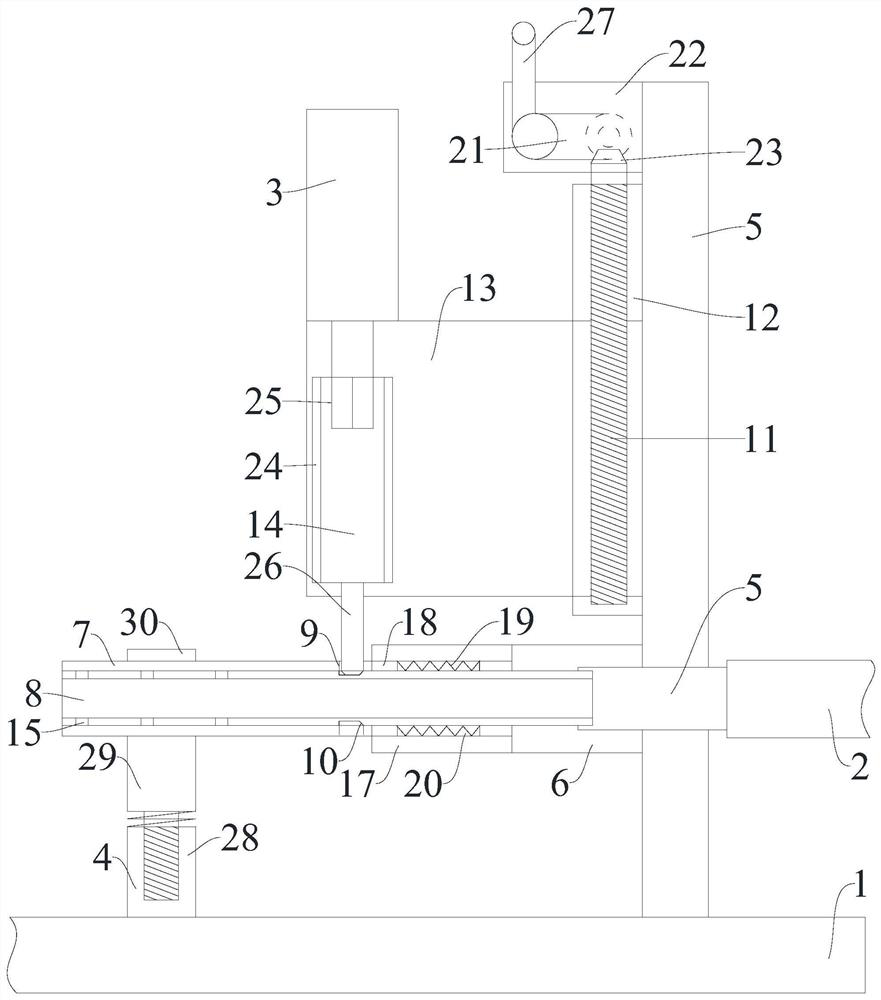

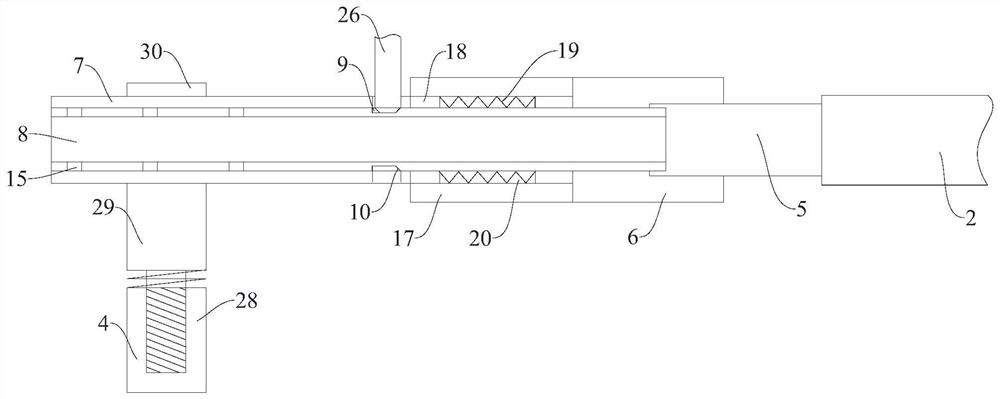

[0022] Embodiment: People first rotate the external control handle 27 to drive the threaded screw 11 to rotate, control the internal thread lifting seat 13 to rise, then drive the transmission shaft 26 to separate from the inside of the tapered transmission tooth groove 10, and then pull out the external turning catheter 7 to the left , to separate it from the horizontal assembly connecting tube 6, then turn the external turning tube 7 forward, wrap the pig small intestine outside the external turning tube 7, then turn it over and reset it, and then insert it into the horizontal fitting connecting tube 6 to the right, and finally reverse it. Rotate the external control handle 27 to drive the threaded screw 11 to rotate, control the internal thread lifting seat 13 to descend, make the drive shaft 26 mesh with the inside of the tapered drive tooth groove 10, turn on the booster pump, and control the cleaning fluid to the internal rotary water pipe 8 internal drainage, and then th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com