Lateral bending forming tool for guide arm

A guide arm and bending forming technology, which is applied in the field of guide arm side bending forming tooling structure, can solve the problems such as being unable to meet the high-quality and high-efficiency requirements of enterprises, affecting the processing efficiency of the guide arm, and enhancing the work intensity of laborers, so as to reduce the number of workers. The effect of flipping action, reducing heat consumption and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

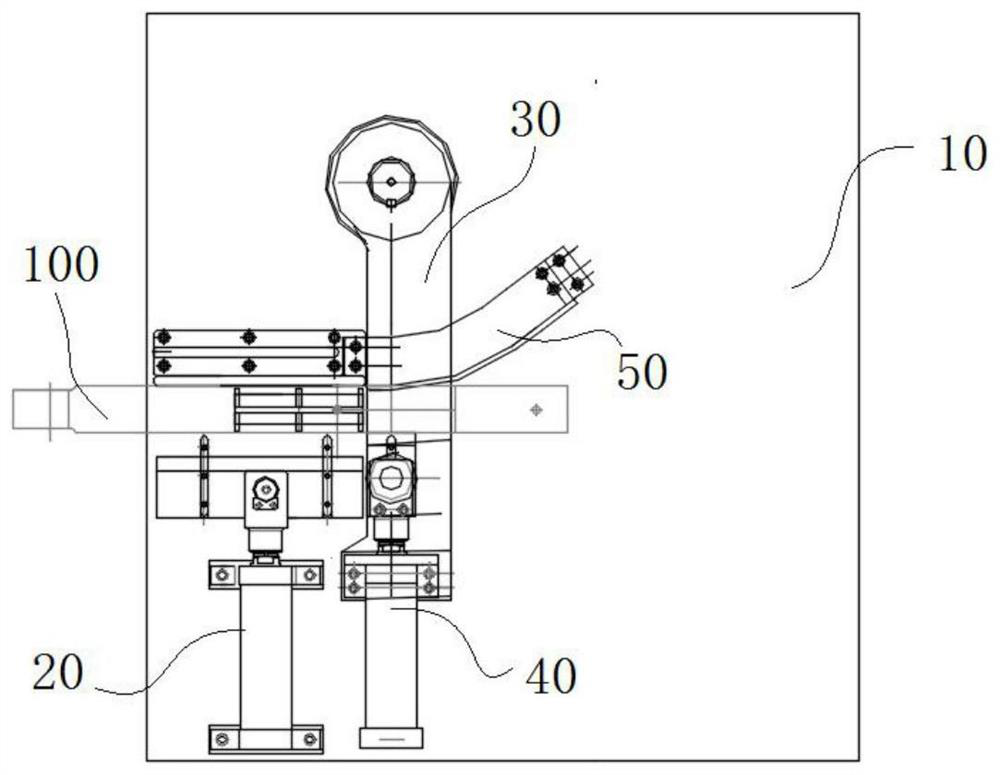

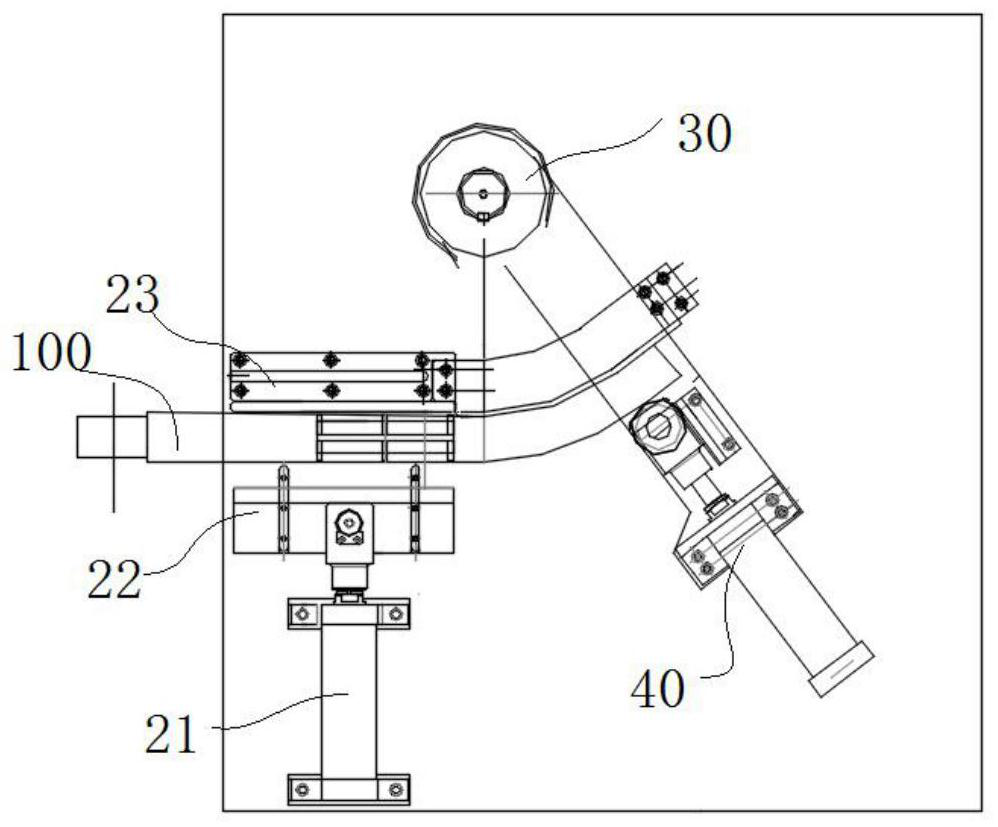

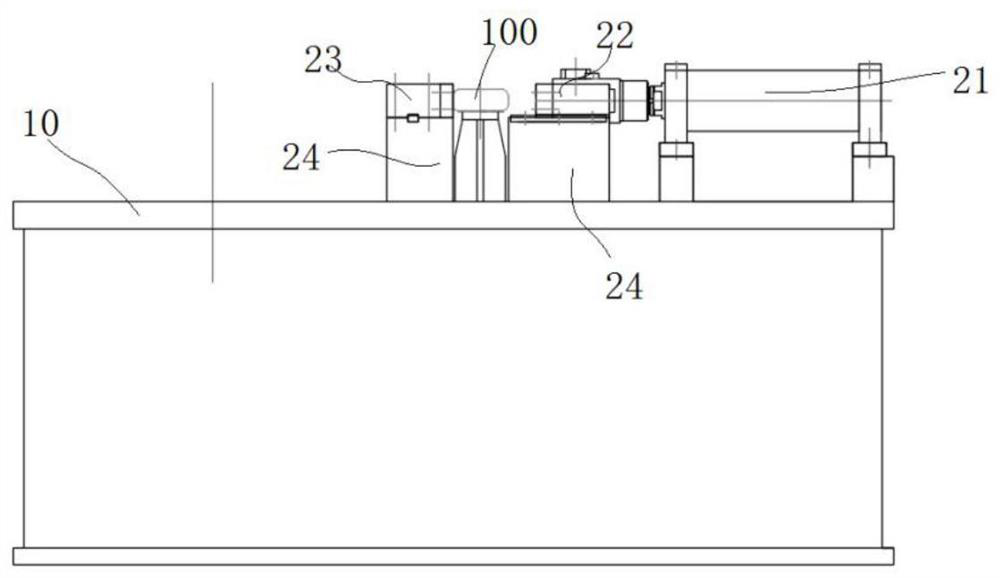

[0030] This embodiment provides a guide arm side bending forming tooling, see Figure 1-Figure 4 , including a tooling table 10, the tooling table 10 plays a supporting role, so that the guide arm 100 can be processed and bent on the tooling table 10; the tooling table 10 is provided with a clamping mechanism 20, a rotary mechanism 30 and an abutting mechanism 40 The clamping mechanism 20, the turning mechanism 30 and the abutting mechanism 40 cooperate with each other to realize the direct bending and forming of the guide arm without changing the direction.

[0031] Specifically, the clamping mechanism 20 is directly fixed to the tooling table 10, and the feeding manipulator grabs the guide arm onto the clamping me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com