Steel casting protection device

A protection device, steel technology, used in casting melt containers, metal processing equipment, casting equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

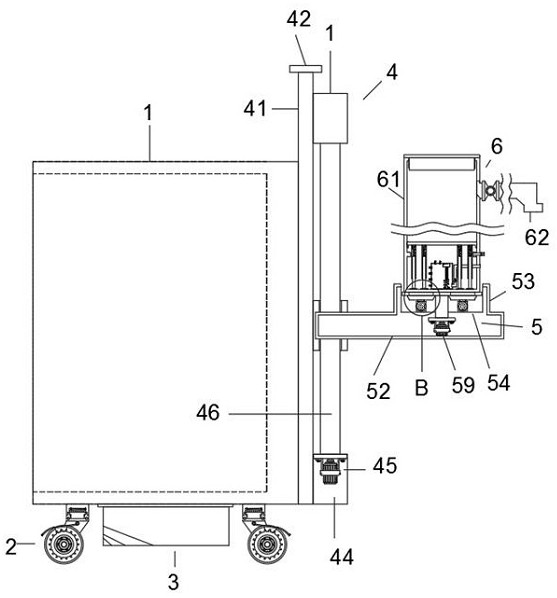

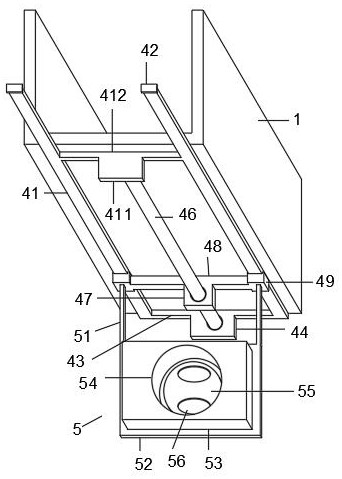

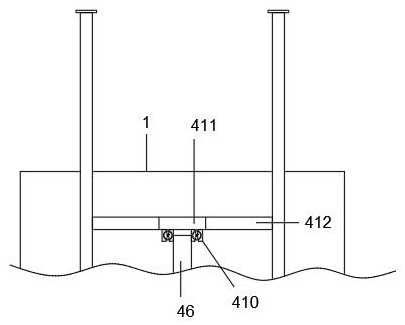

[0036] Such as Figure 1-9 As shown, this specific embodiment adopts the following technical solutions: a steel pouring protection device, including a protective plate 1 and a universal wheel 2, the design of the protective plate 1 can protect the mold, and avoid pouring due to the problems of the mold itself. failure, the shape of the protective plate 1 is C-shaped, two universal wheels 2 are installed on the bottom of the protective plate 1, and the bottom of the protective plate 1 between the universal wheels 2 is provided with an anti-dumping mechanism 3, and the protective plate 1 side is equipped with a feeding mechanism 4, the feeding mechanism 4 is provided with a rotating mechanism 5, the rotating mechanism 5 is provided with a storage mechanism 6, and a buffer mechanism 7 is arranged in the storage mechanism 6, and the storage mechanism 7 between the buffer mechanisms A power mechanism 8 is arranged inside the material mechanism 6 , and an auxiliary mechanism 9 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com