Steel pipe polishing device for protection fence

A technology of polishing device and guardrail, which is applied in the direction of grinding drive device, grinding/polishing equipment, machine tool with surface polishing, etc., can solve the problems of low steel pipe grinding efficiency and low displacement degree of grinding block.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

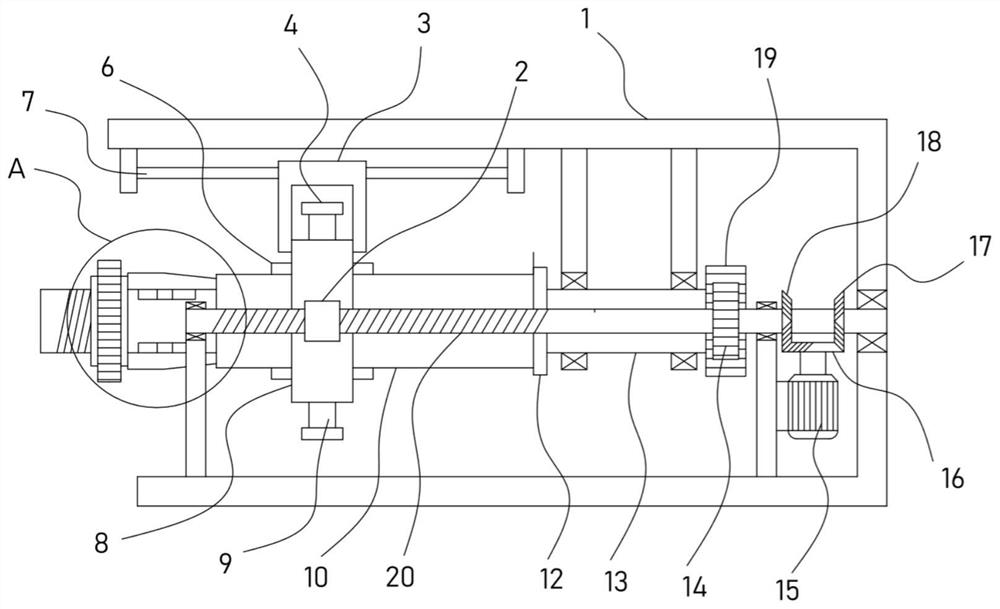

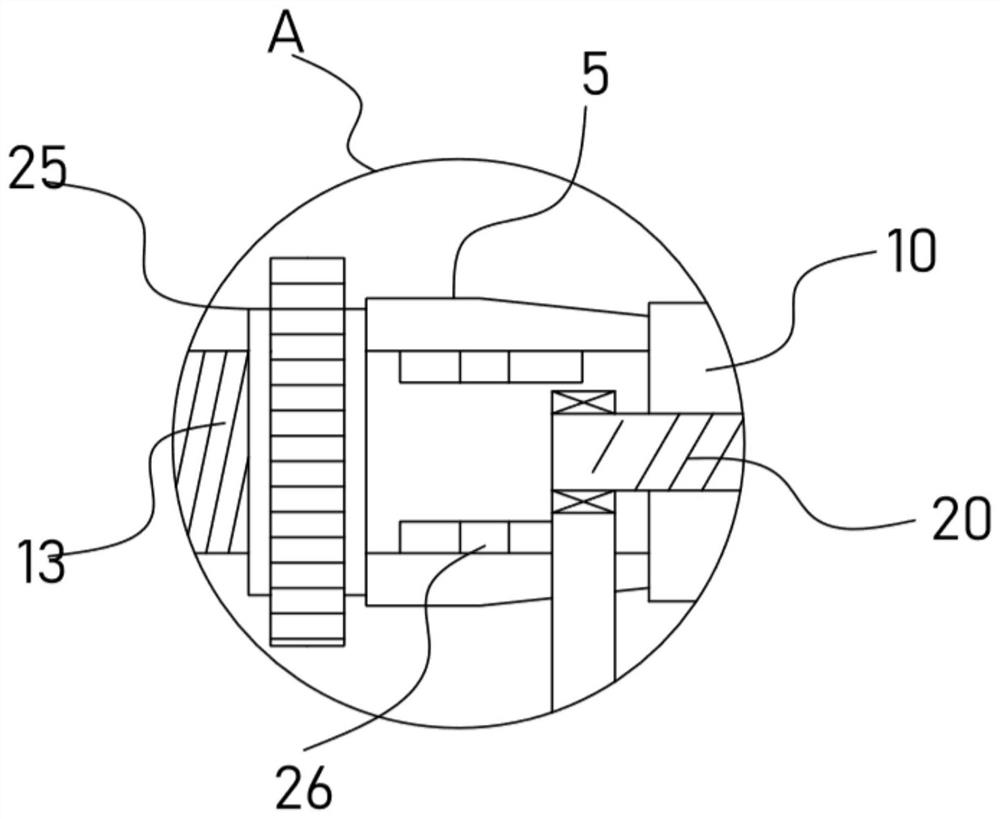

[0023] see Figure 1-4 , a steel pipe grinding and polishing device for a guardrail, comprising a support frame 1, a rotating shaft 13 is mounted on the support frame 1, a steel pipe 10 is sleeved on the rotating shaft 13, and the support frame 1 is provided with a The limit mechanism, the support frame 1 is hung with a guide frame 3, the guide frame 3 is fixed with a collar 8 sleeved outside the steel pipe 10, and the collar 8 is provided with a grinding mechanism for grinding the steel pipe 10, so A servo motor 15 is fixed on the support frame 1 , and a translation mechanism for driving the collar 8 to move laterally relative to the steel pipe 10 is connected to the servo motor 15 .

[0024] In the process of grinding and polishing the surface of the steel pipe 10, the device sets the steel pipe 10 on the rotating shaft 13, and limits the position of the steel pipe 10 through the set limit mechanism, so that the steel pipe 10 rotates with the rotation of the rotating shaft 1...

Embodiment 2

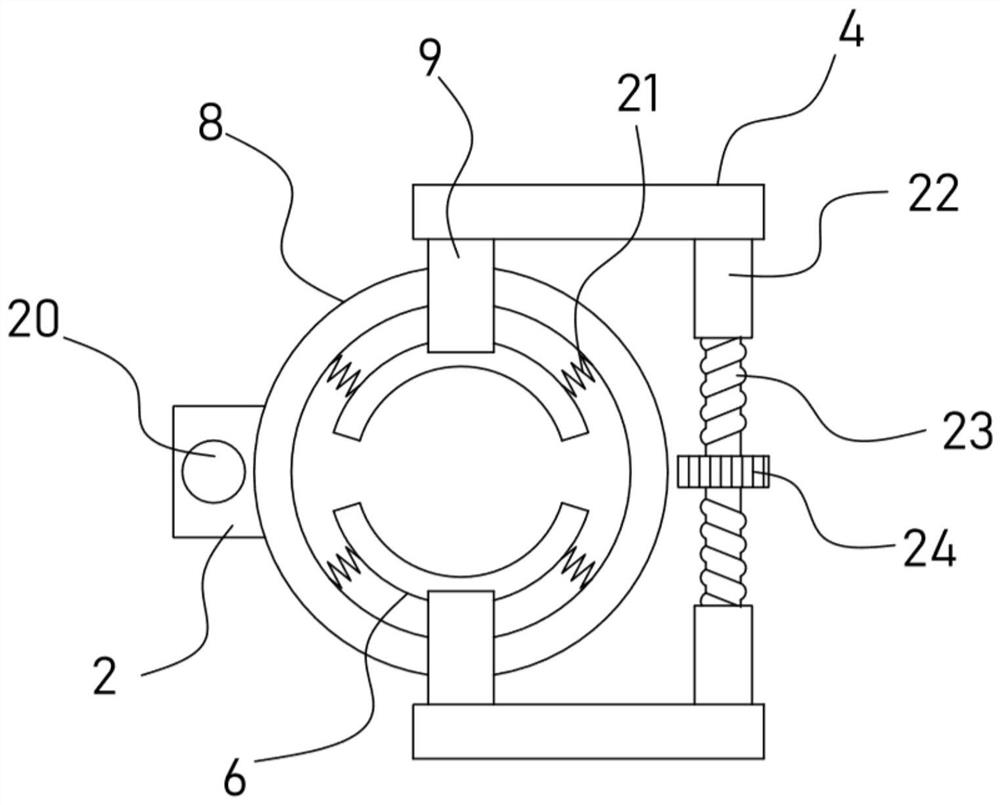

[0029] On the basis of Embodiment 1, in addition, in order to flexibly adjust the distance between the two grinding arc plates 6 to ensure sufficient grinding and pressing force, and to adapt to the surface polishing treatment of steel pipes 10 with different outer diameters, this device is also designed There is an adjustment mechanism, which specifically includes two threaded columns 23 fixed coaxially and with opposite screw directions. The threaded columns 23 are threaded with a threaded sleeve 22, and a connecting plate 4 is fixed on the threaded sleeve 22. The connecting plate 4 An adjustment column 9 vertically penetrating through the side wall of the collar 8 is fixed on the top, and the adjustment column 9 is arranged in contact with the grinding arc plate 6 , and a spring 21 is fixed between the grinding arc plate 6 and the collar 8 .

[0030] Through the above setting, the runner 24 fixed on the threaded column 23 is rotated and sleeved, and the runner 24 drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com