Calcium carbonate pulverizing and feeding mechanism

A feeding mechanism and calcium carbonate technology, applied in the direction of conveyors, conveyor objects, loading/unloading, etc., can solve the problems of inconvenient transportation devices, inconvenient unloading, etc., to improve the flexibility and practicability of use, and to achieve efficient crushing materials, improving efficiency and fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

[0020] Among them, the drawings are only used for exemplary description, which are only schematic diagrams rather than physical drawings, and cannot be understood as a limitation of the patent; in order to better illustrate the embodiments of the present invention, some parts of the drawings may be omitted, Enlargement or reduction does not represent the actual product size.

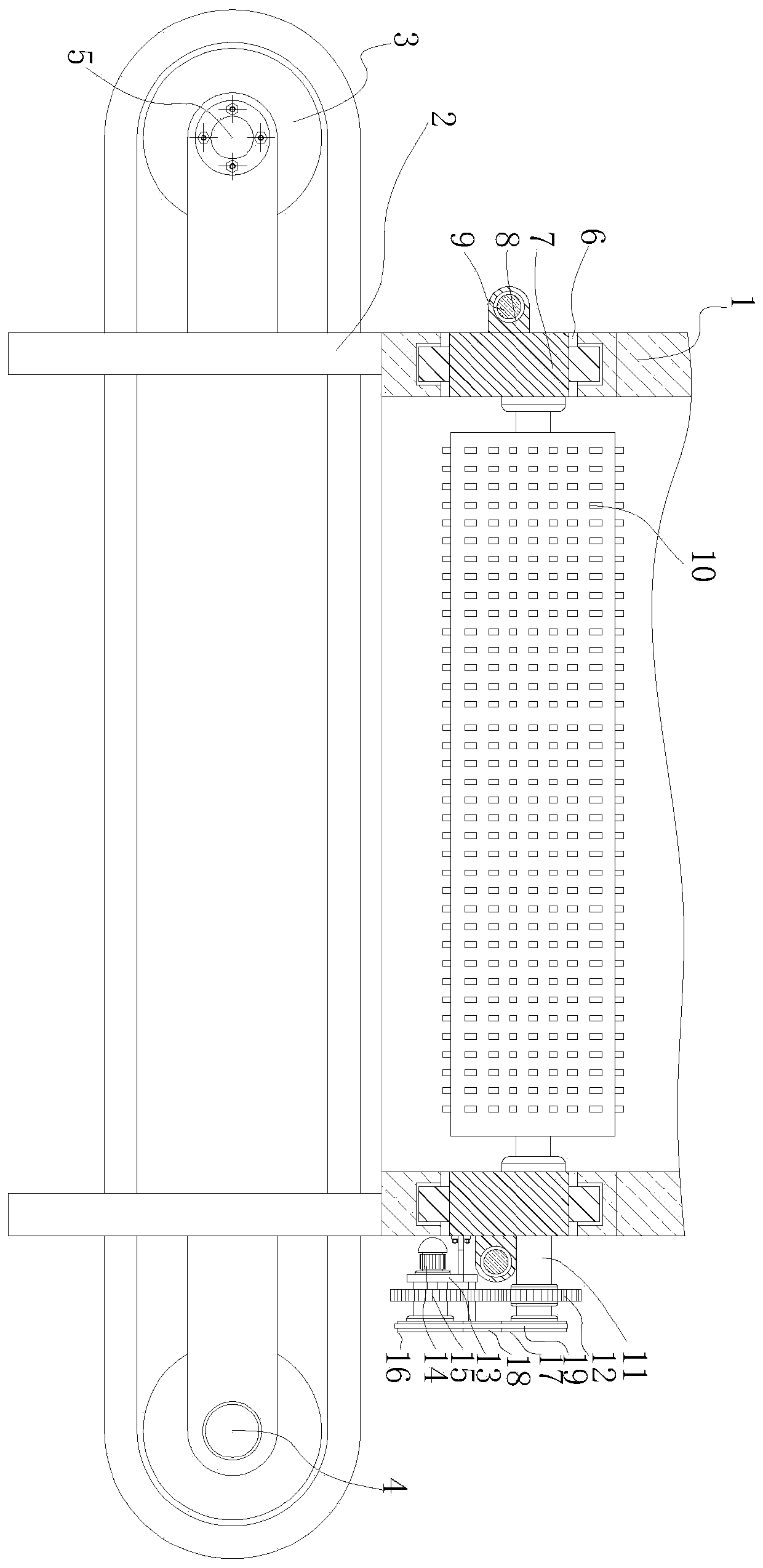

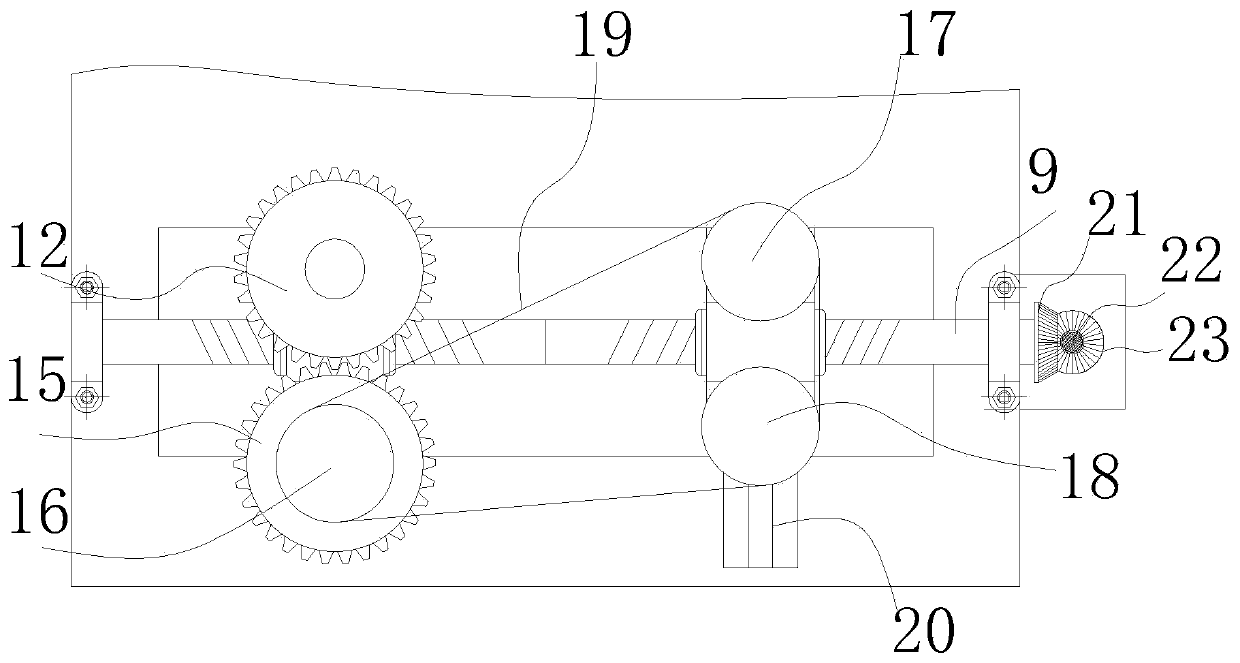

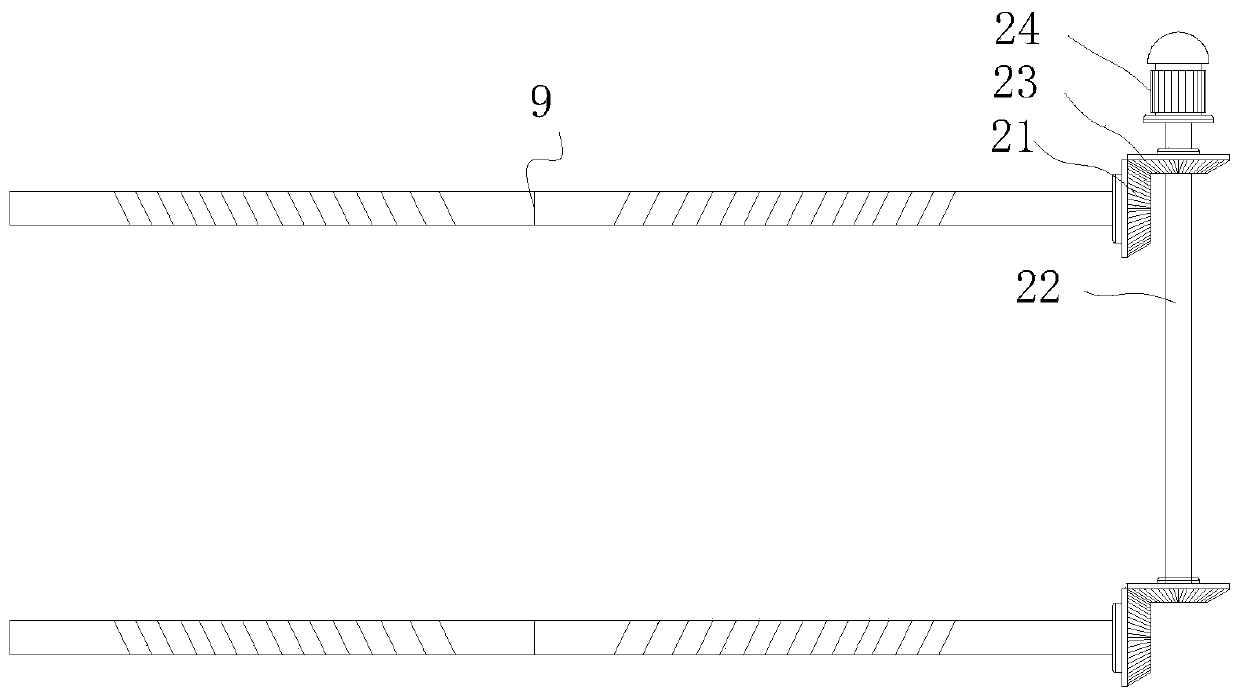

[0021] Reference Figure 1 to Figure 3 The shown calcium carbonate crushing and feeding mechanism includes a drying box and a conveying mechanism provided at the lower end of the drying box. The drying box is composed of a box body 11 and a discharge opening 1 provided at the lower end of the box body 11. The discharging port 1 is provided with a discharging auxiliary mechanism. The discharging auxiliary mechanism is composed of two crushing rollers 10 arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com