Automatic printing equipment with drying function

A technology of printing equipment and functions, applied in the field of automatic printing equipment, can solve the problems of easy contamination, affecting the production quality of storage boxes, and the printing machine does not have a drying function, so as to speed up ink drying, fast drying, and ensure production quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below:

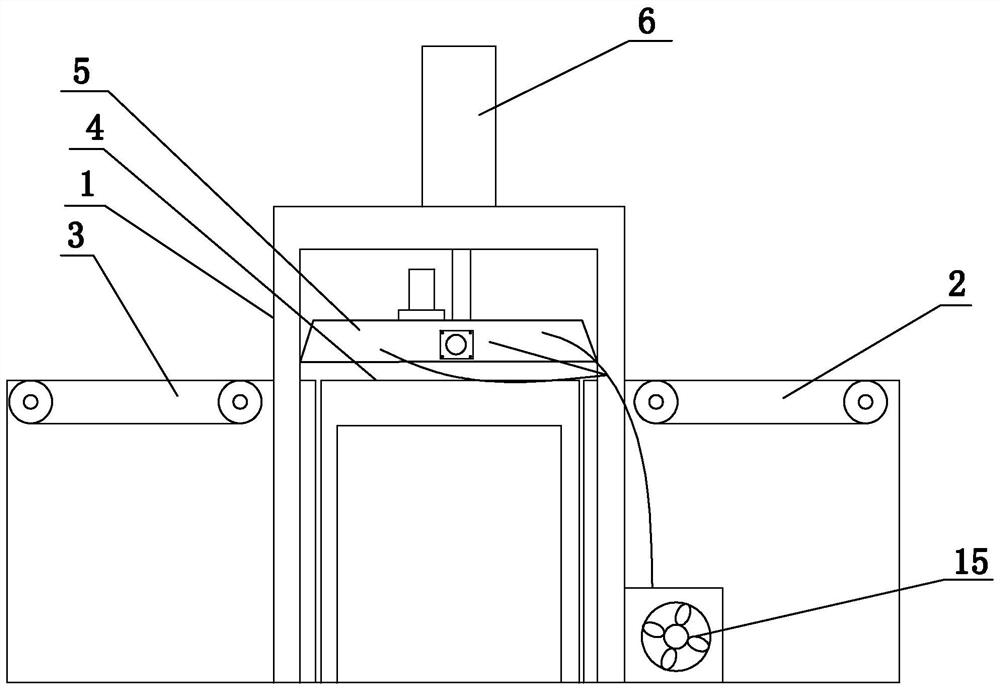

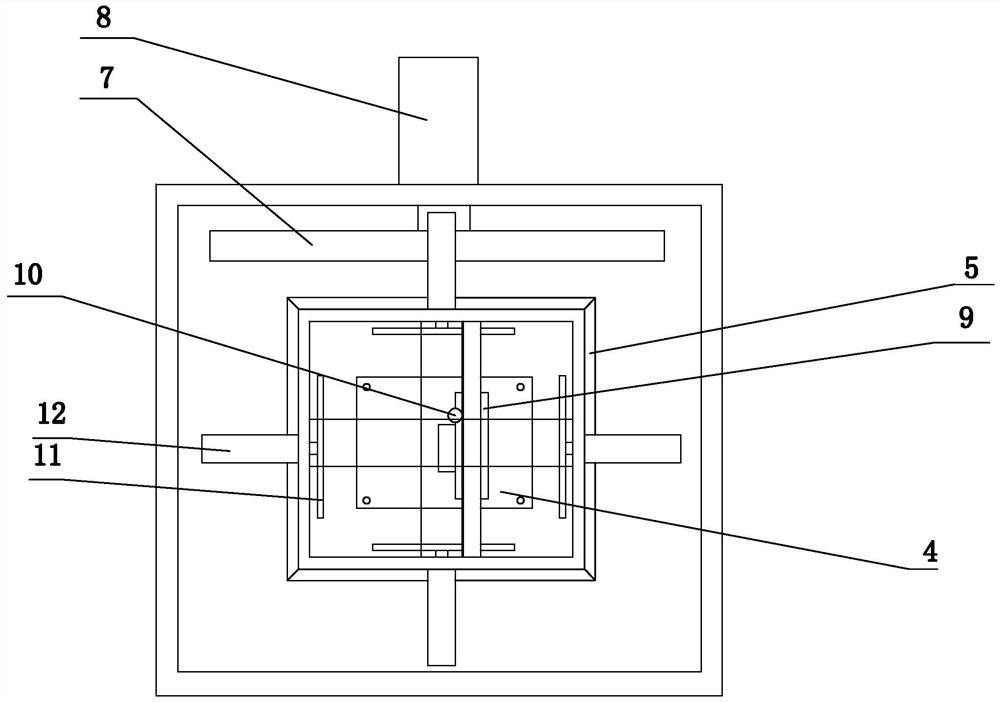

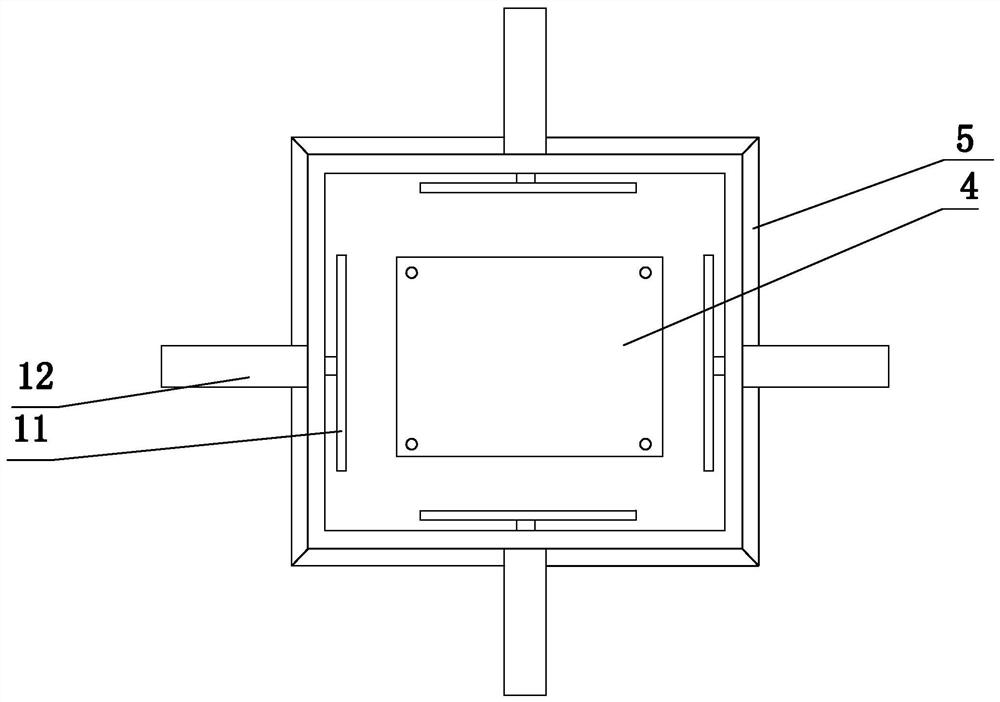

[0023] An automatic printing device with a drying function, including a frame 1, a first conveyor belt 2, a second conveyor belt 3, a workbench 4, a mounting frame 5, a first cylinder 6, a printing plate assembly, a correction assembly and an unloading assembly, The workbench 4, the first conveyor belt 2 and the second conveyor belt 3 are all installed on the frame 1, the workbench 4 is located in the middle of the frame 1, and the first conveyor belt 2 and the second conveyor belt 3 are respectively located on the left and right sides of the workbench 4 , and the first conveyor belt 2 and the second conveyor belt 3 respectively abut against the carton inlet end and the carton outlet end of the workbench 4, the mounting frame 5 is suspended above the workbench 4, and the upper end of the mounting frame 5 is connected with a The frame 5 moves up and down the first cylinder 6 along the frame 1, the first cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com