Residual liquid recovery system of PTA hydrogen recovery device

A recovery device and recovery system technology, applied in the direction of hydrogen separation, etc., can solve the problems of waste, increase the cost of environmental protection treatment, etc., achieve the effect of constant temperature, eliminate hydrogen accumulation and explosion, and avoid personnel poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

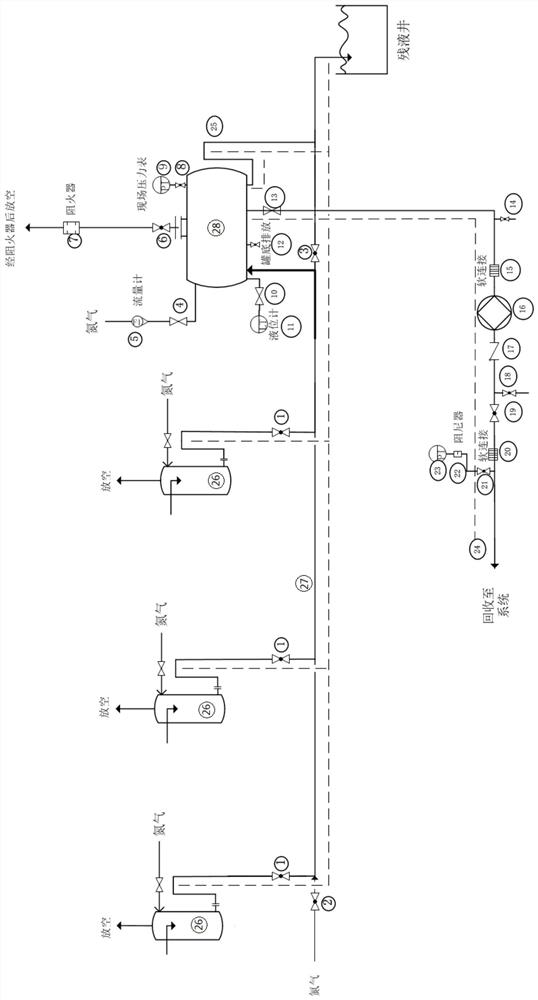

Embodiment 1

[0019] A kind of raffinate recovery system of PTA hydrogen recovery device, comprises raffinate discharge tank 26, is also provided with raffinate recovery tank 28, and raffinate discharge tank is connected with described raffinate recovery tank through raffinate main line 27; Described raffinate recovery The side of the tank is provided with a raffinate delivery pump 16, and the raffinate is pumped to the PTA production oxidation device through the raffinate delivery pump; the raffinate recovery tank is also provided with a liquid level gauge 11, a gas phase venting pipeline, an overflow discharge pipeline 25, an on-site pressure Table 9. Tank bottom discharge valve 12. When there are more than two residual liquid discharge tanks, a residual liquid isolation valve 1 is provided before the discharge pipelines of each residual liquid discharge tank converge to the main line. The residual liquid recovery tank is an atmospheric tank. The overflow discharge pipeline is an inverte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com