Efficient and automatic reservoir bottom de-silting ecological reef

An automatic, reservoir-bottom technology, applied in biological sludge treatment, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems of high water content in sludge, difficult transportation, unrealistic lake and reservoir areas, etc., and achieve strong adsorption Ability to guarantee long-term effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

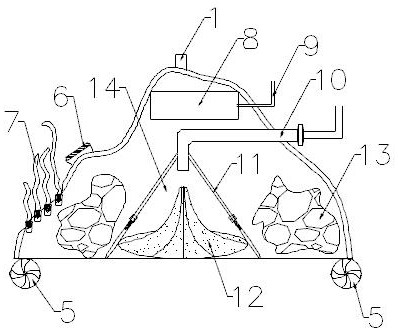

Embodiment 1

[0023] Specific as figure 1 As shown, the outlet of the pipeline 10 is directly facing the bubble diffusion plate 12, that is, the injected bubbles and the bubble diffusion plate 12 form an angle of 90°, so that the pressurized microbubbles and micro-nano bubbles collide with the bubble diffusion plate and accumulate work, and the bubbles are separated gradually. Level mutual push, to realize the diffusion of bubbles from the surface to the vertical three-dimensional diffusion, a large number of nano-scale and ultra-nano-scale bubbles, with strong adsorption capacity, they also have a strong ability to release negative ions, and their microelectrodes can electrolyze water molecules Hydroxyl negative ions, such hydroxyl negative ions and subsequent hydroxyl radicals have a strong decomposition ability, which can not only effectively decompose harmful substances adsorbed in the micropores of the microbial solid carrier 13, but also make the microbial solid carrier 13 self-cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com