Waste sintered brick and tile environment-friendly lightweight concrete and preparation method thereof

A lightweight concrete and environment-friendly technology, applied in the field of concrete, can solve the problems of low flexural strength of lightweight aggregate concrete, achieve the effects of improving thermal insulation effect, reducing bulk density, and increasing compressive strength and flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

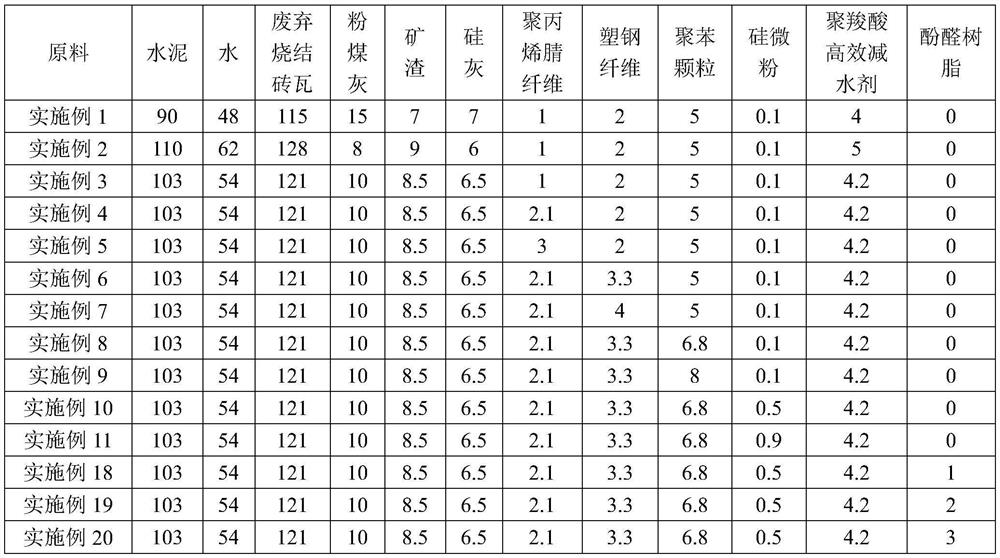

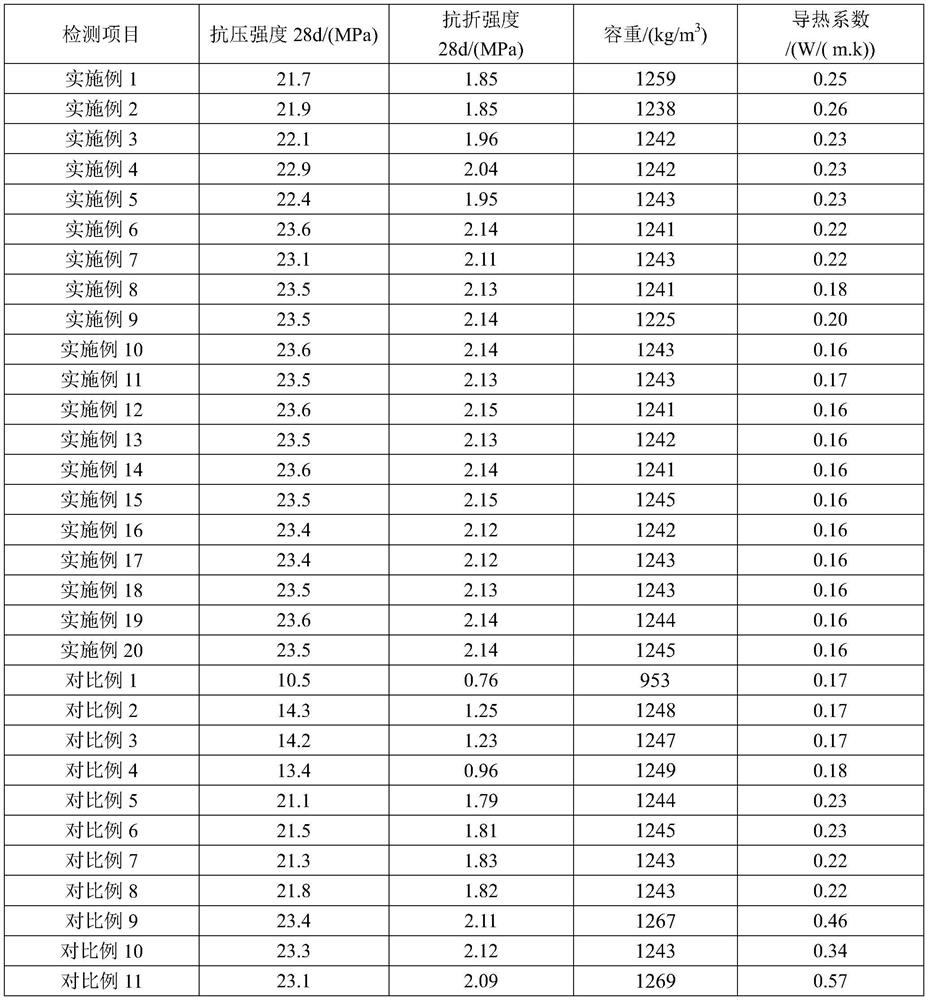

[0040] A kind of environmentally friendly lightweight concrete with waste fired bricks and tiles, its raw material ratio is shown in Table 1.

[0041] The preparation method of lightweight concrete comprises the steps:

[0042] Spray soaking water into the waste sintered bricks and tiles, and the amount of soaking water is 13% of the weight of the waste sintered bricks and tiles to obtain the mixture A;

[0043] Spray adsorption water into the fly ash, the amount of water for adsorption is 35% of the weight of the fly ash to obtain the mixture B;

[0044] Mix cement, slag, silica fume, polyacrylonitrile fiber, plastic steel fiber, polystyrene particles, silicon micropowder, polycarboxylate superplasticizer, mixture A, mixture B, and the remaining water to obtain lightweight concrete .

[0045] Among them, the average length of polyacrylonitrile fibers is 4 mm, the average length of plastic steel fibers is 2 mm, the average particle size of silicon micropowder is 25 μm, and t...

Embodiment 2-11

[0049] An environment-friendly lightweight concrete with waste fired bricks and tiles. The difference between Examples 2-11 and Example 1 is that the ratio of raw materials is different, and the ratio of raw materials is shown in Table 1.

Embodiment 12

[0051] An environment-friendly lightweight concrete for waste fired bricks and tiles. The difference between this embodiment and Example 10 is that in the preparation method of environment-friendly lightweight concrete, the amount of soaking water is 10% of the weight of waste fired bricks and tiles , the amount of water for adsorption is 30% of the weight of fly ash, and the average length of polyacrylonitrile fibers is 3mm, the average length of plastic steel fibers is 3mm, the average particle diameter of silicon micropowder is 50μm, and the average particle diameter of polystyrene particles 1mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com