Metroxylon sagu starch scraping device

A coconut tree and starch technology, applied in the field of starch production, can solve the problems of wasting labor, inability to separate starch, arm pain, etc., and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

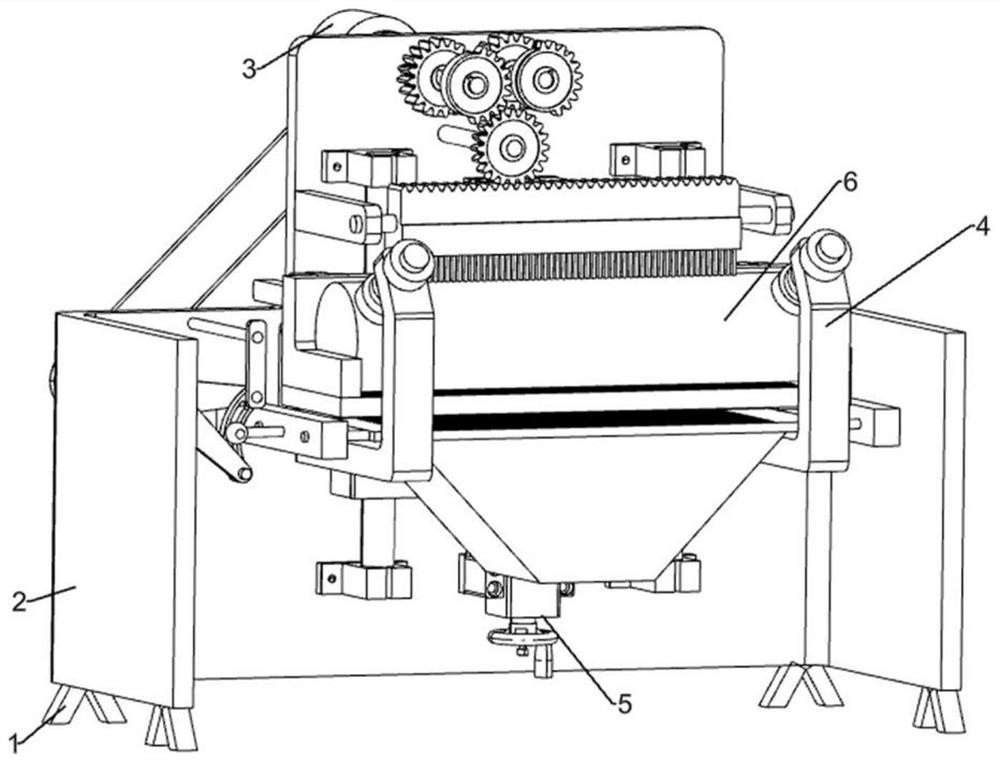

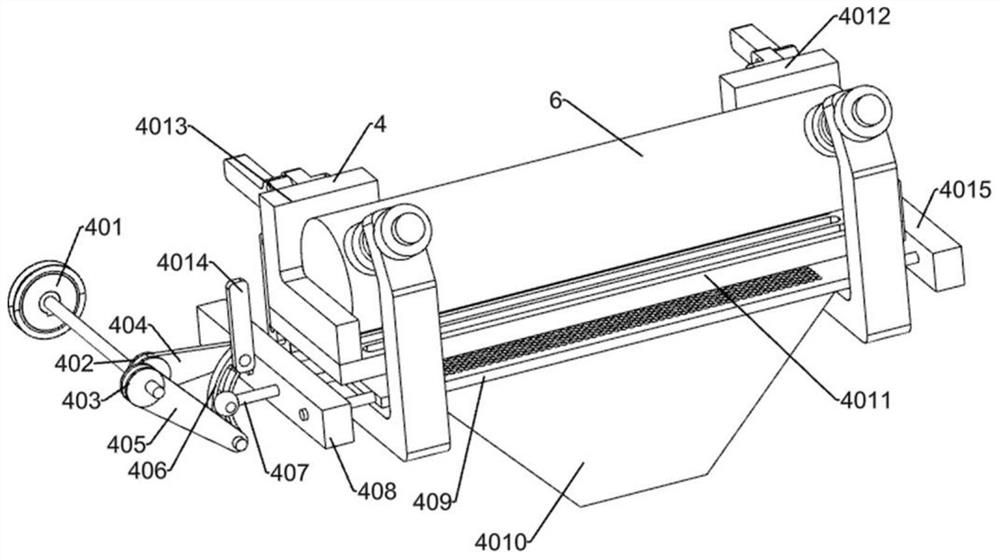

[0025] A device for scraping sago palm starch, such as Figure 1-5 As shown, it includes foot 1, frame 2, powder scraping mechanism 3, fixing mechanism 4, auxiliary mechanism 5 and copra 6; the upper end of foot 1 is fixedly connected to frame 2; the top of frame 2 is fixedly connected to powder scraping mechanism 3; the front middle part of the frame 2 is fixedly connected to the fixing mechanism 4; the front middle part of the frame 2 is fixedly connected to the auxiliary mechanism 5, and the front part of the auxiliary mechanism 5 is connected to the fixing mechanism 4; copra 6 is placed on the fixing mechanism 4, and The outer upper end of the copra 6 is connected to the powder scraping mechanism 3 .

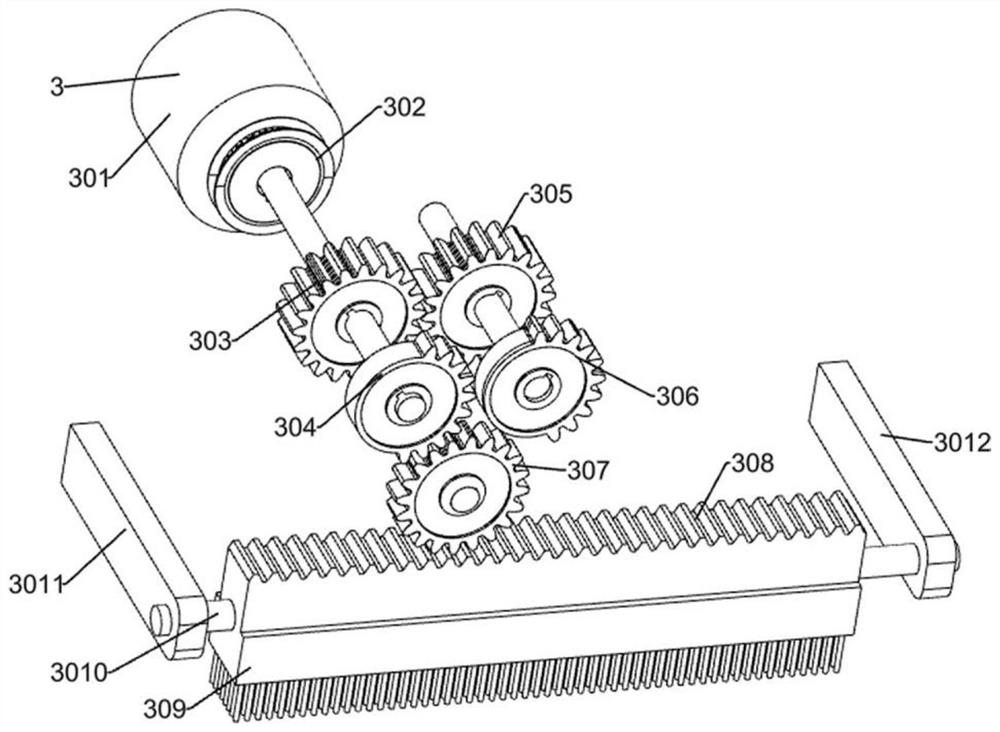

[0026] Powder scraping mechanism 3 comprises motor 301, first transmission wheel 302, first gear 303, first half gear 304, second gear 305, second half gear 306, third gear 307, rack 308, wire brush 309, the first A slide bar 3010, a first bracket 3011 and a second bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com