A kind of polyurethane elastic fiber with antiskid elastic performance and preparation method thereof

A technology of polyurethane elasticity and elastic performance, applied in the field of polyurethane elastic fiber and its preparation, can solve the problems of easy retraction of spandex, and achieve the effects of improving friction, not easy to slide, and large friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] In an embodiment of the present invention, the preparation method of the composite polyurethane elastic fiber comprises:

[0043] The polyurethane urea spinning stock solution is passed through a spinneret having more than 2 spinneret holes, and after entering the spinning shaft, it is finally formed by a false twist device through a winding machine, and finally the polyurethane elastic fiber with anti-slip elastic properties is obtained;

[0044] Among them, the spinning oil can be added after the polyurethane elastic fiber passes through the false twisting device and before being formed by the winding machine;

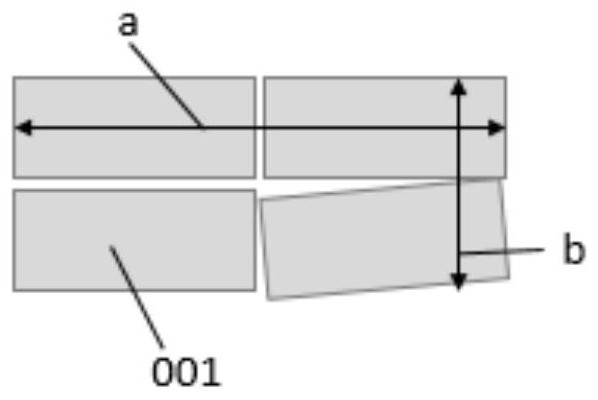

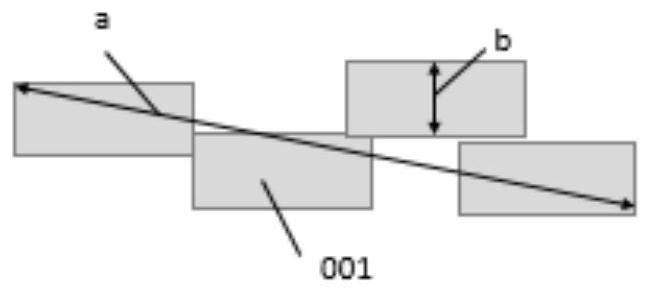

[0045] The shape of the spinneret is circular, rectangular or cross-shaped;

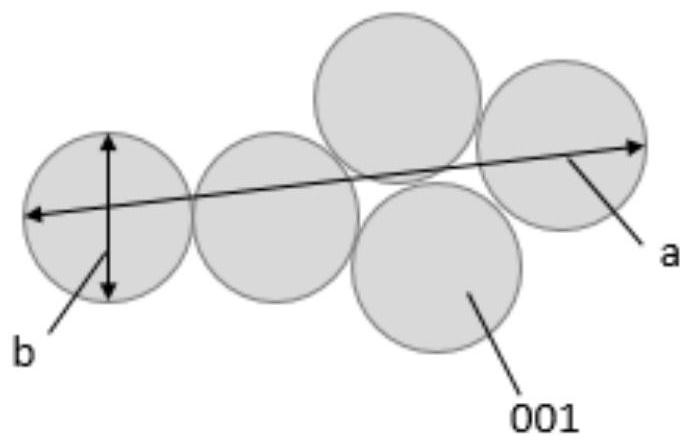

[0046] Further, the arrangement of the spinneret holes is "...", "····", "·····", "...", "∷", "∷∷";

[0047] Further, the spinneret holes of the spinneret are arranged in a "line" shape;

[0048] As an example, the arrangement of the spinneret holes is "...", "····", "·····", "····...

Embodiment 1

[0066] A kind of polyurethane elastic fiber with non-slip elastic performance of the present invention and preparation method thereof are as follows:

[0067] Preparation of control polyurethane elastic fiber:

[0068] Add 15.000kg DMAC and 25.000kg PTMG (Mn is 1800) in turn in the reaction tank, add 6.043kg MDI according to the NCO / OH molar ratio of 1.75:1; the reaction temperature is controlled at 50°C, and the reaction time is 120min. Protection, obtain polymer solution A;

[0069] Cool the obtained polymer A to 10°C, add a mixed DMAC solution (6.0% concentration) containing 0.5754kg ethylenediamine + 0.1125kg, and fully stir the reaction to obtain a spinning stock solution with a concentration of 35.0%;

[0070] Add 2.4% additives to the spinning dope in the form of functional auxiliary materials, mix them, stir evenly, mature, pass through the spinneret assembly (3 holes / round / "∴" type), spinning tunnel, false twist device, and warp Winding machine, obtain contrast poly...

Embodiment 2

[0072] A kind of polyurethane elastic fiber with non-slip elastic performance of the present invention and preparation method thereof are as follows:

[0073] Preparation of control polyurethane elastic fiber:

[0074] Add 15.000kg DMAC and 25.000kg PTMG (Mn is 1800) in turn in the reaction tank, add 6.043kg MDI according to the NCO / OH molar ratio of 1.75:1; the reaction temperature is controlled at 50°C, and the reaction time is 120min. Protection, obtain polymer solution A;

[0075] Cool the obtained polymer A to 10°C, add a mixed DMAC solution (6.0% concentration) containing 0.5754kg ethylenediamine + 0.1125kg, and fully stir the reaction to obtain a spinning stock solution with a concentration of 35.0%;

[0076] Add 2.4% additives to the spinning dope in the form of functional auxiliary materials, mix them, stir evenly, mature, pass through the spinneret hole assembly (4 holes / round / "∷" type), spinning tunnel, false twist device, and warp Winding machine, obtain contrast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com