Natural power air-cooling and smoke white removing device and smoke white removing method

A flue gas and power technology, applied in chemical instruments and methods, separation methods, climate sustainability, etc., can solve the problems of increasing the space occupied by equipment, and achieve the effect of saving space and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principle and spirit of the present invention will be described below with reference to several exemplary embodiments shown in the accompanying drawings. It should be understood that these implementations are described only to enable those skilled in the art to better understand and implement the present invention, but not to limit the scope of the present invention in any way.

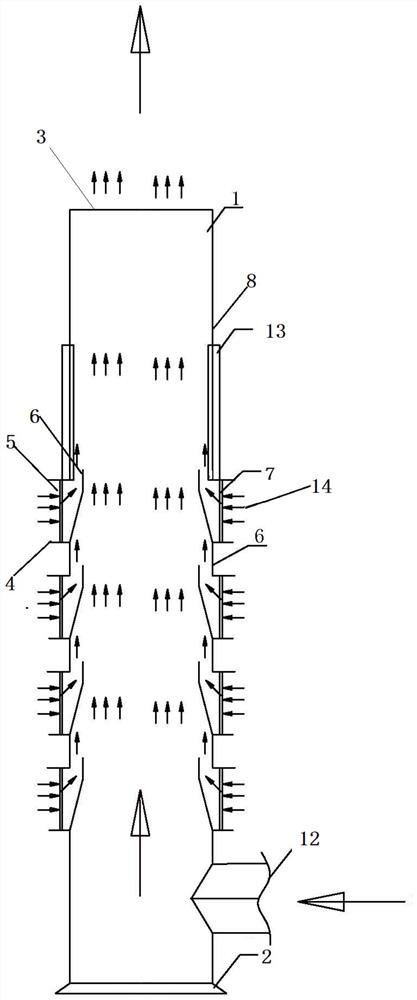

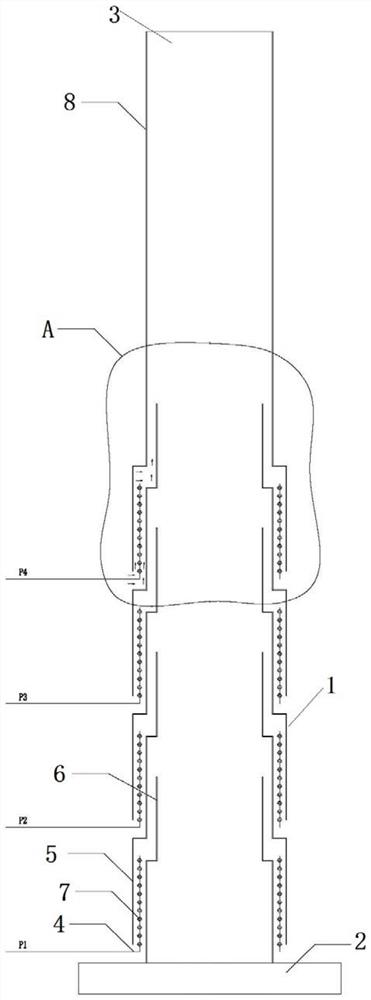

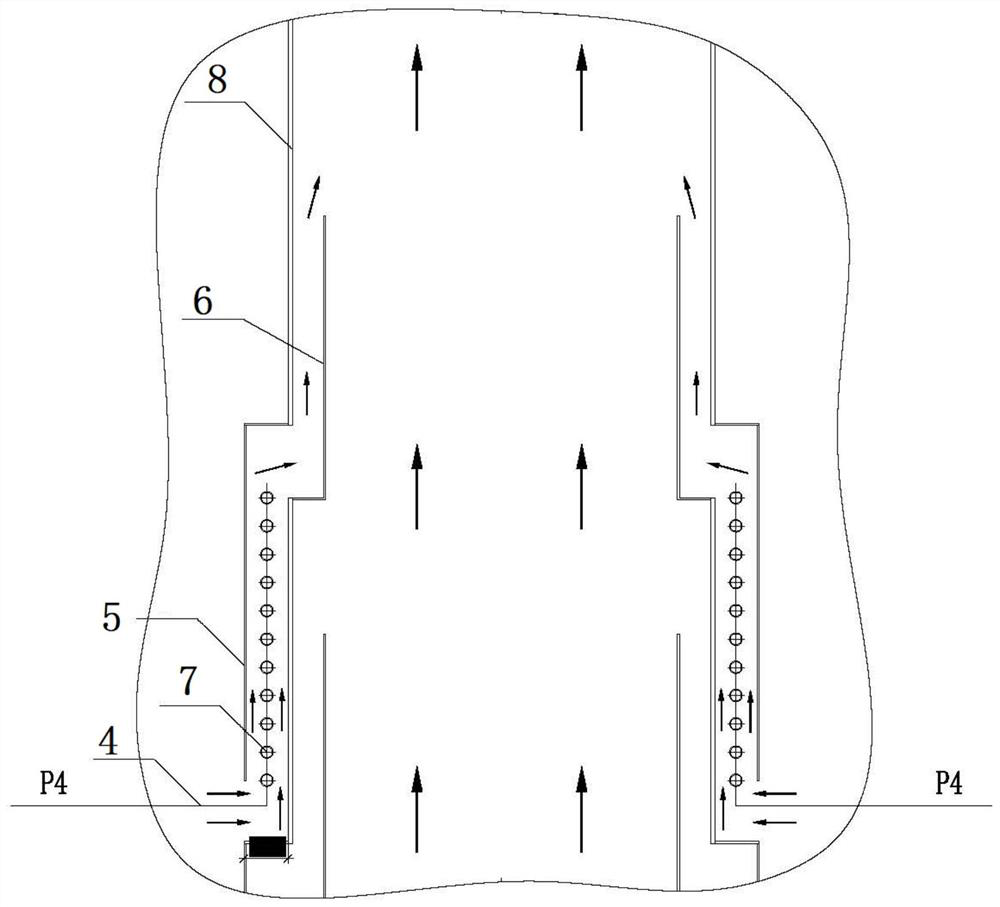

[0031] Please refer to Figure 1-3 , the embodiment of the present invention provides a natural power air cooling and flue gas dewhitening device. In addition to flue gas dewhitening, the device can also be used in other scenarios that require cooling or heating.

[0032] The device includes a cylinder body 1, which can be a cylinder or a polygonal cylinder, and the bottom of the cylinder body 1 can be set on a foundation 2. In some embodiments, the upper end of the cylinder 1 is provided with a flue gas outlet 3 directly above, and the lower end is provided with a flue gas inlet 12 , whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com