Machine tool turntable comprehensive thermal error detection device and installation method

A detection device, thermal error technology, applied in the direction of computer control, instruments, simulators, etc., can solve the problems of low measurement efficiency, difficult operation of the device, high cost, etc., and achieve the effect of overcoming high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with accompanying drawing:

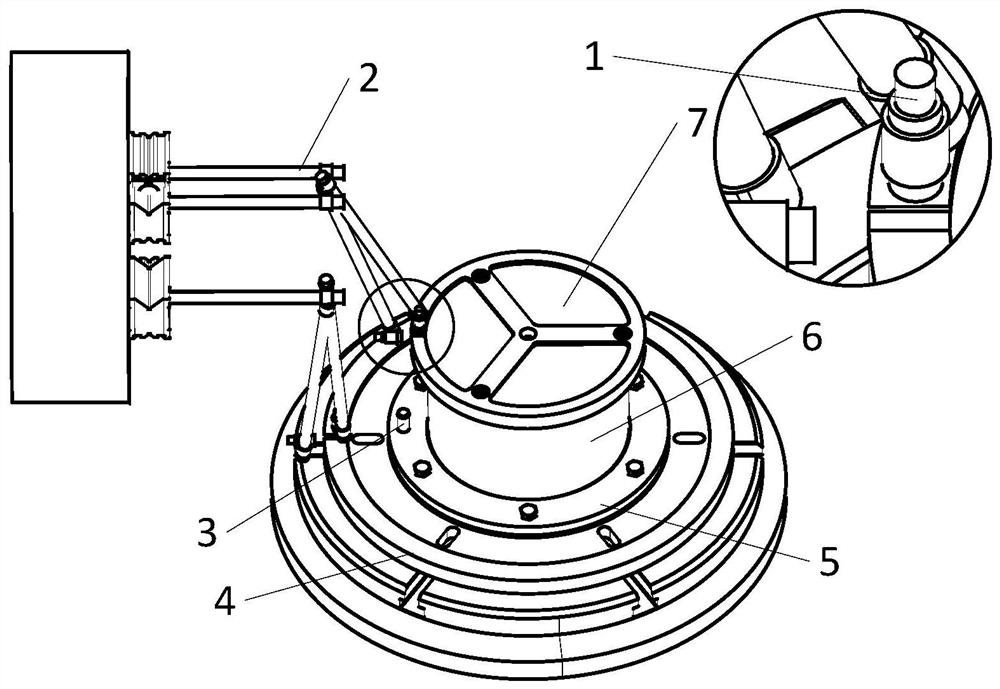

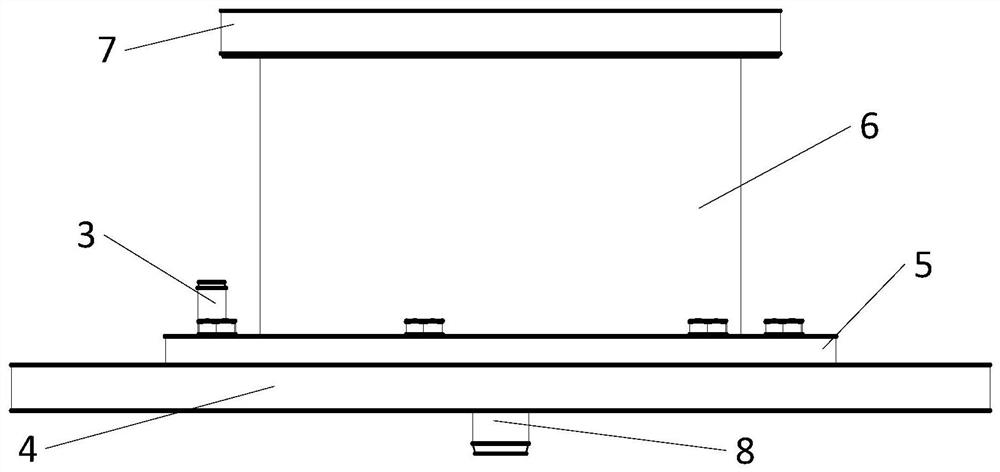

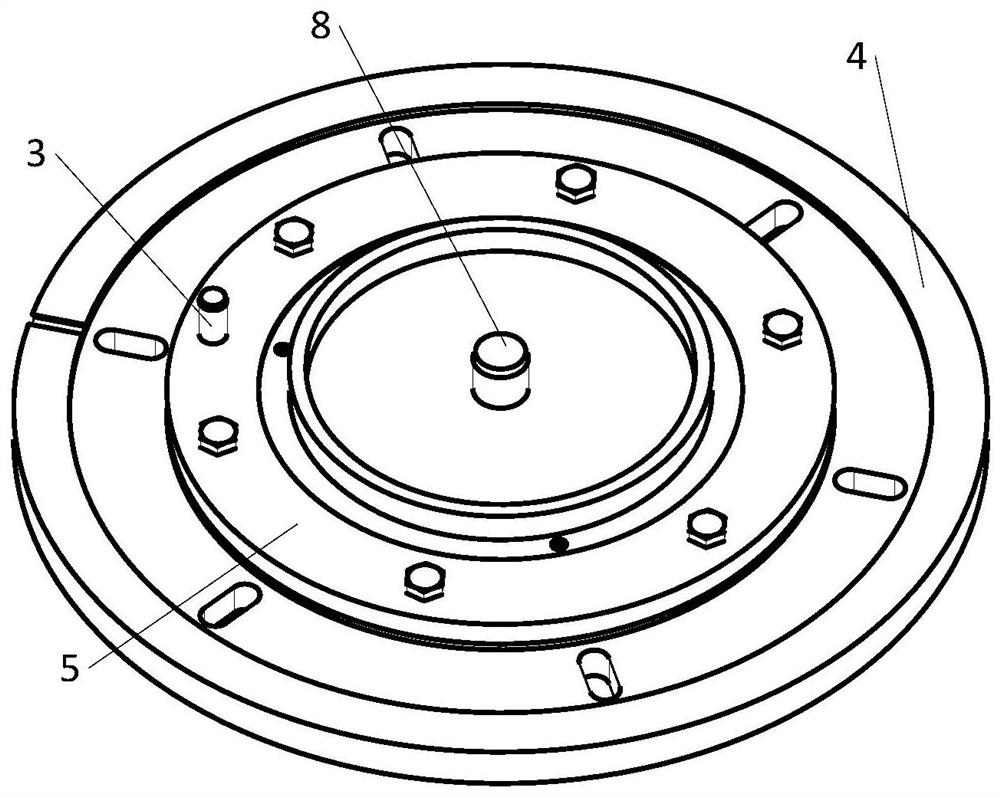

[0026] refer to Figure 1 to Figure 4 , the present invention is based on a comprehensive thermal error detection device for a machine tool turntable, which is mainly divided into a sensor module and a reference round table module. 3. Base 4, bottom plate 5, support cylinder 6, top plate 7 and positioning pin 8; the magnetic base 2 and eddy current sensor 1 are adsorbed on the main shaft; the data acquisition system is connected with a computer and can be displayed in real time by testing software The data measured by the sensor; the side and the edge of the top surface of the base 4 and the top plate 7 are precision-machined to ensure its accuracy; The T-shaped groove of the platform is threaded; the bottom plate 5 is radially fixed with the base 4 through the positioning pin 8, and then the base 4 is threaded with the threaded hole on the bottom plate 5; the support cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com