Quantitative analysis method for influence degree of papermaking fiber characteristics on mechanical properties of finished paper

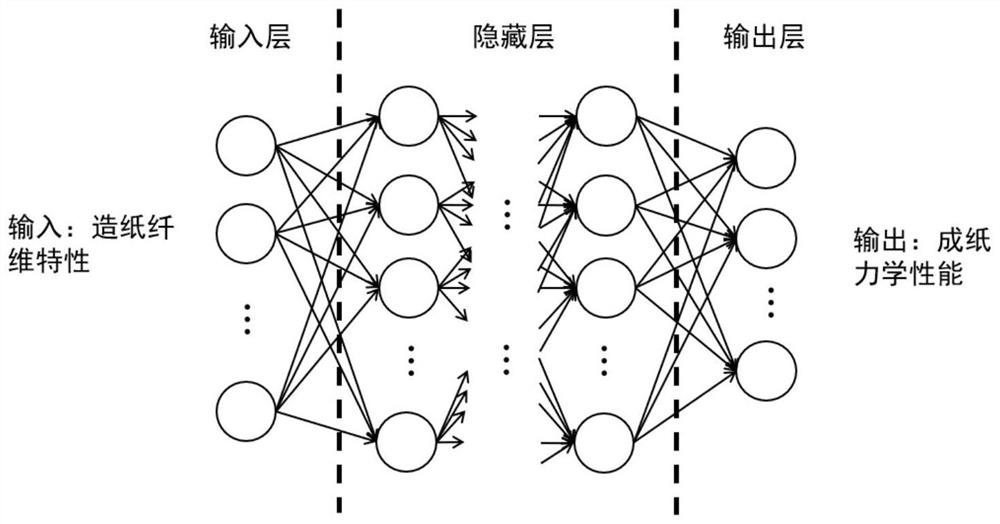

A technology for quantitative analysis of fiber characteristics, applied in neural learning methods, instruments, biological neural network models, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

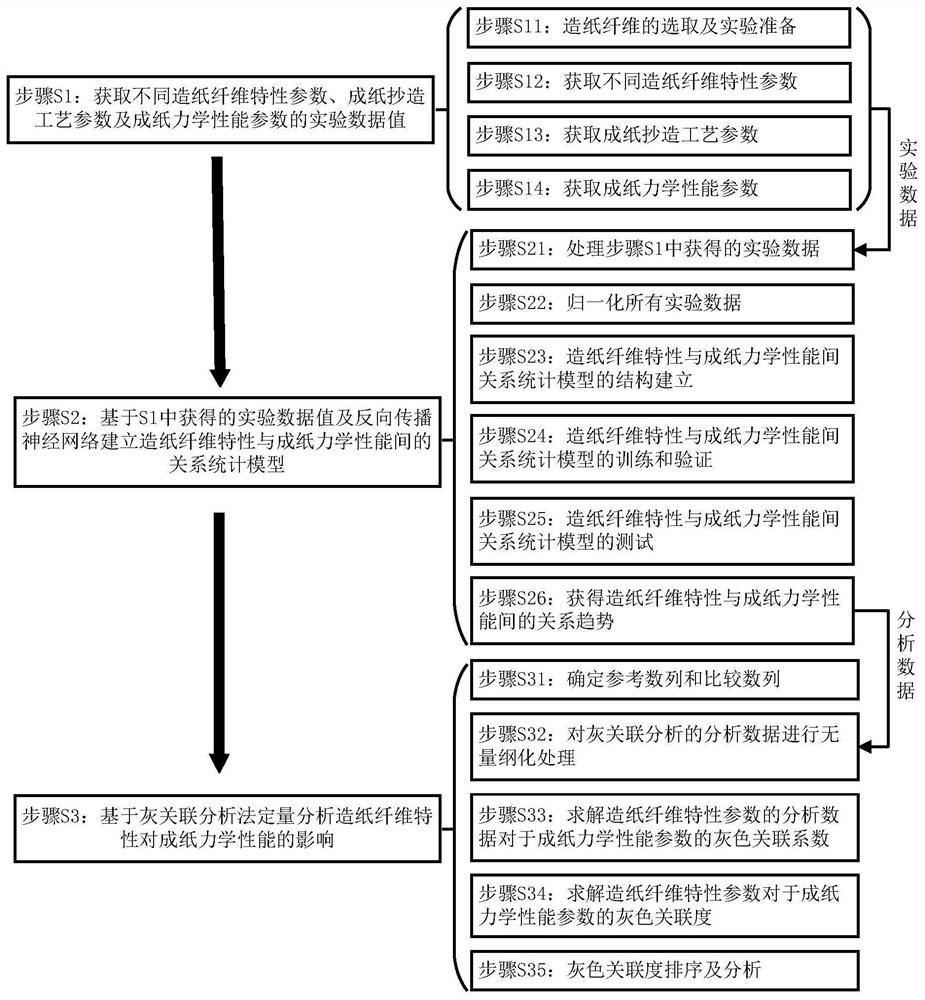

[0052] This embodiment discloses a gray relational quantitative analysis method for the analysis of the degree of influence of papermaking fiber characteristics on the mechanical properties of paper, including 3 steps (such as figure 1 shown), the specific description is as follows:

[0053] S1. Obtain experimental data of different papermaking fiber characteristic parameters, papermaking process parameters and paper mechanical performance parameters;

[0054] In order to analyze the influence of papermaking fiber characteristics on the mechanical properties of paper and establish a statistical model of the relationship between the two, it is necessary to first obtain the experimental data of relevant parameters. The relevant parameters to be considered include: different papermaking fiber characteristic parameters, papermaking process parameters And paper mechanical performance parameters. The specific steps for obtaining parameters are described as follows.

[0055] S11. S...

Embodiment 2

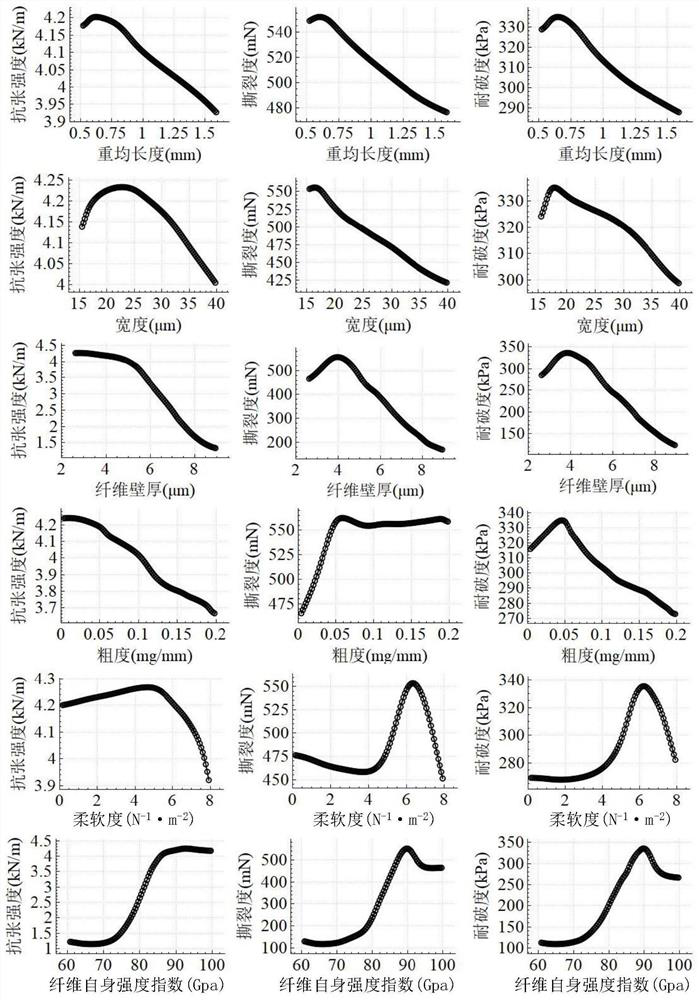

[0116] In this example, 5 commonly used paper-making fiber materials, eucalyptus fiber, coniferous wood fiber, cotton fiber, bagasse fiber and bamboo fiber, are selected for experimental analysis. The papermaking fiber characteristic parameters considered include: fiber length, fiber diameter, fiber wall thickness, fiber thickness, fiber softness and fiber strength index; the considered papermaking process parameters include pulp beating degree; the considered paper mechanical performance parameters include : Tensile strength, tear and burst resistance.

[0117] The specific implementation process of the quantitative analysis of the influence of papermaking fiber characteristics on the mechanical properties of paper is as follows:

[0118] Step T1:

[0119] According to the method described in step S1 in Example 1, the five kinds of papermaking fiber materials to be selected were used to obtain papermaking fiber characteristic parameters (fiber length, fiber diameter, fiber w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com