Auxiliary power supply device of guide rail electric locomotive, guide rail electric locomotive and power supply method of guide rail electric locomotive

A technology for electric locomotives and auxiliary power supply, applied in circuit devices, output power conversion devices, electrical components, etc., can solve the problems of large volume of auxiliary power supply equipment, inconvenient maintenance and disassembly, high manufacturing cost, etc., and achieve small space occupation and convenience Dismantling and repairing, strong maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

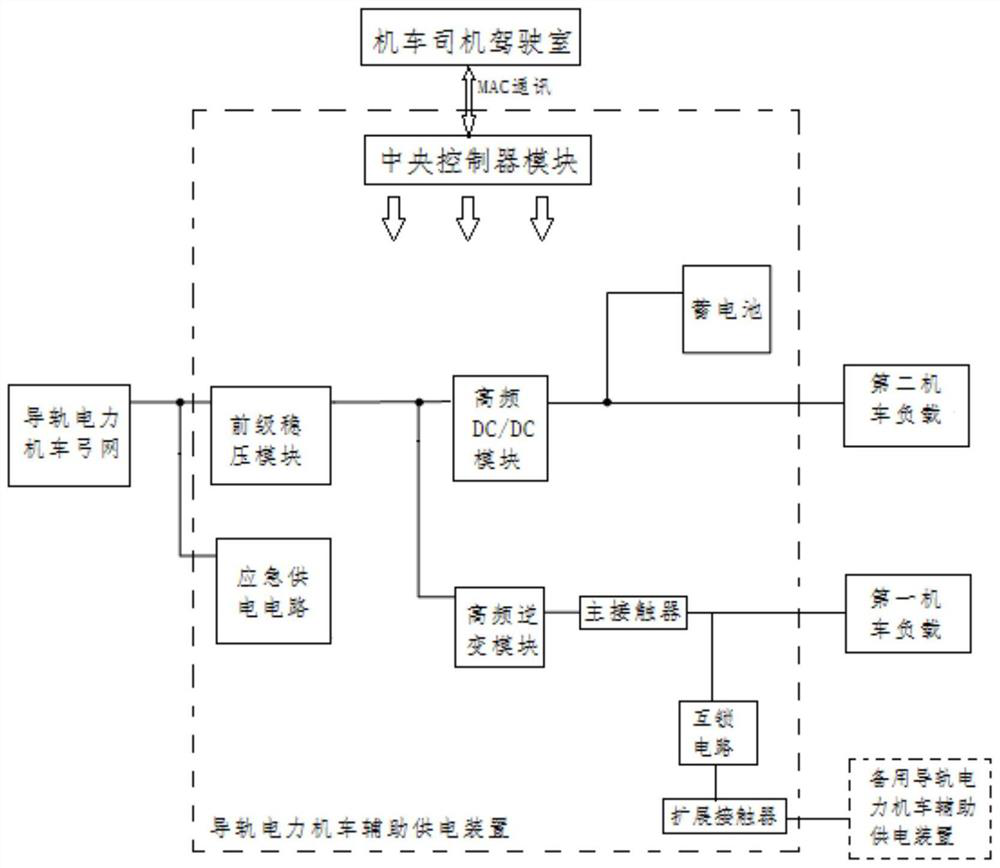

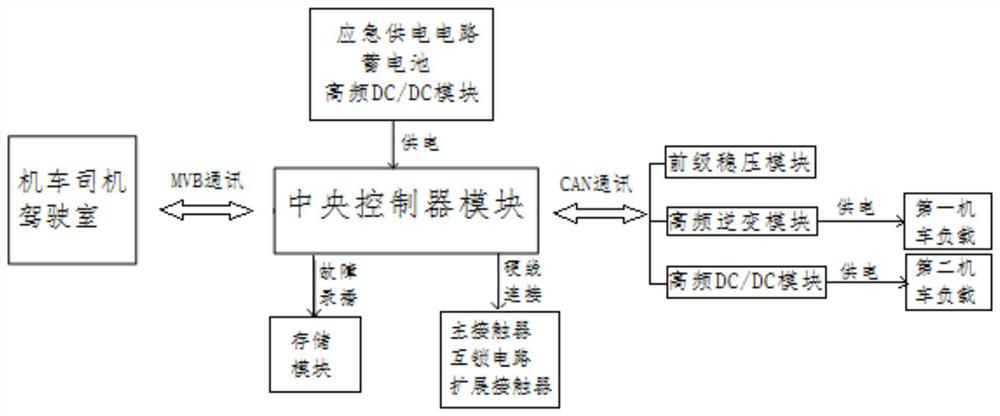

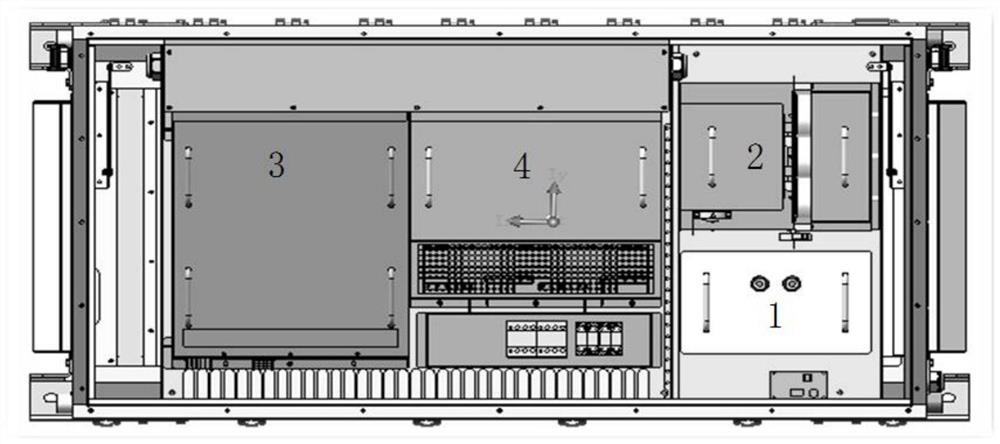

[0049] Such as Figure 1-Figure 3 As shown, an auxiliary power supply device for a guide rail electric locomotive includes a central controller module 1 inserted in the same housing, two pre-stage voltage stabilizing modules, a high-frequency inverter module 3, a high-frequency DC / DC module 4, a battery, Emergency power supply circuit, interlock circuit, main contactor and extension contactor.

[0050] The MVB communication mechanism is adopted between the central controller module and the locomotive driver's cab, and the CAN communication mechanism is adopted between the pre-stage voltage stabilization module, high-frequency inverter module and high-frequency DC / DC module, and the interlock circuit and main contact The controller and the expansion contactor are connected by hard wires; it should be noted that the electrical wiring met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com