Ultrathin foil transferring and processing method capable of reducing curling of ultrathin foil and preventing folding thereof

An ultra-thin, thin foil technology, applied in thin material processing, winding/folding electrodes, winding strips, etc., can solve problems such as sheet bending, prevent ultra-thin foil folding, and improve ultra-thin foil bending phenomenon , the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0125] Electrode Preparation (Example)

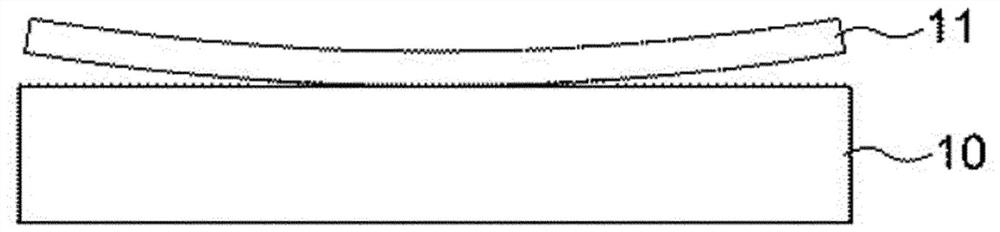

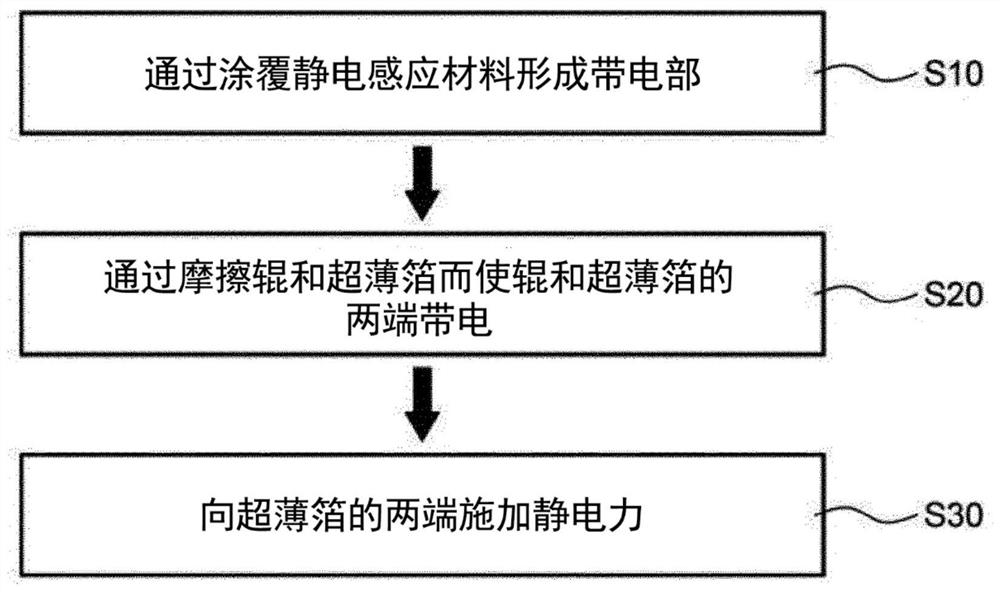

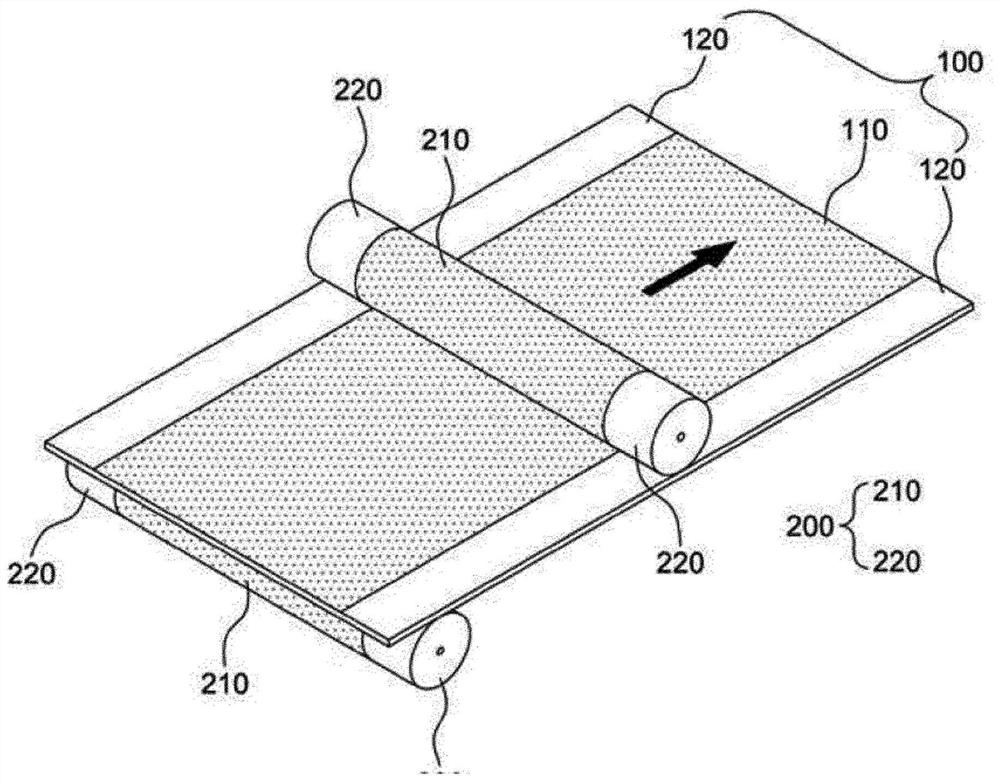

[0126] Using copper foil with a width of 1000 mm and a thickness of 10 μm as an ultra-thin foil of an electrode collector, a cylindrical hard rubber with a width of 50 mm was processed and mounted on both ends of a roller used in the electrode manufacturing process. In addition, a non-conductive tape made of Teflon for induction electrification was attached to both ends of the ultrathin foil.

[0127] In addition, in conveyance of the ultrathin foil, a positively charged nickel electrode is provided on the inner surface of the curved surface formed on the ultrathin foil along the conveyance direction. The charged body is placed at a distance of 20mm from the ultra-thin foil.

[0128] Add 95% by weight of carbon mixture (electrode active material), 2.5% by weight of Super-C (conductive agent) and 2.5% by weight of SBR (binder) to CMC (Carboxymethylcellulose, carboxymethylcellulose, water solvent ) and distilled water in a mixed solutio...

Embodiment 2

[0130] Preparation of separator (example)

[0131] A coating with a thickness of about 0.3 μm was formed by a dip coating method, and a polyolefin-based porous separator (Celgard TM , three-layer polyolefin-based separator) was passed through a solution in which about 4% by weight of PVDF was added to acetone as a solvent.

[0132] In this process, a cylindrical hard rubber having a width of 50 mm is mounted on both ends of the guide roller. In addition, in conveyance of the ultrathin foil, a positively charged nickel electrode is provided on the inner surface of the curved surface formed on the ultrathin foil along the conveyance direction. The charged body is placed at a distance of 20mm from the ultra-thin foil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com