High-temperature-resistant shock-absorbing puncture-proof working shoe and preparation method thereof

A high-temperature-resistant and puncture-resistant technology, applied in footwear, soles, clothing, etc., can solve problems affecting work efficiency, injury, limited shock absorption and energy absorption capacity, etc., and achieve the effect of reducing the heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] In a second aspect, the present invention provides a method for preparing the high-temperature-resistant, shock-absorbing, puncture-resistant work shoes, comprising the following steps:

[0048]Pre-prepared work shoe outsole, anti-puncture layer, aluminum foam layer and shock-absorbing and energy-absorbing layer;

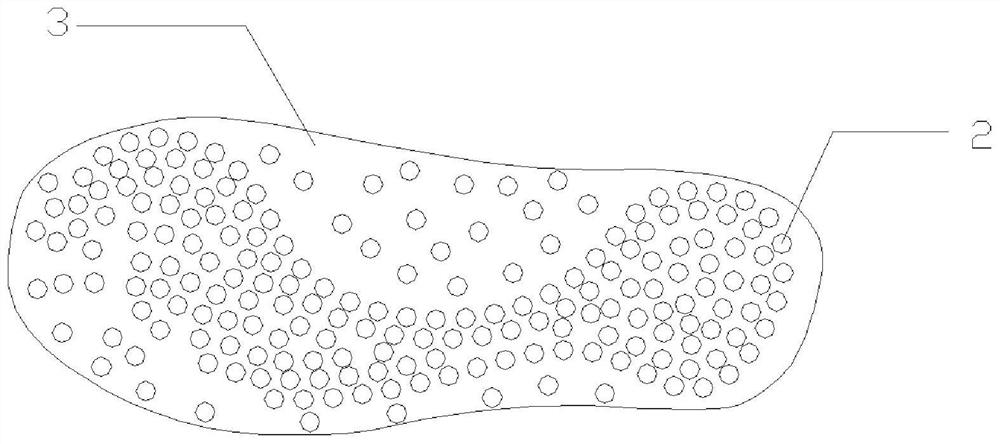

[0049] The preparation method of the shock-absorbing and energy-absorbing layer is as follows: according to the pressure distribution characteristics of the running foot of the human body, the density of the cushioning balls at different parts is set, and the EVA composite material is injected into the mold by a single-shot injection machine. After vacuum pressurization, foaming, and shaping, instant;

[0050] Use high temperature resistant glue to bond each layer of structure, and then use composite bolts to fix the upper and sole;

[0051] Use the fixed edge to cover the periphery of the bonded sole, and complete the production after washing.

[0052] The...

Embodiment

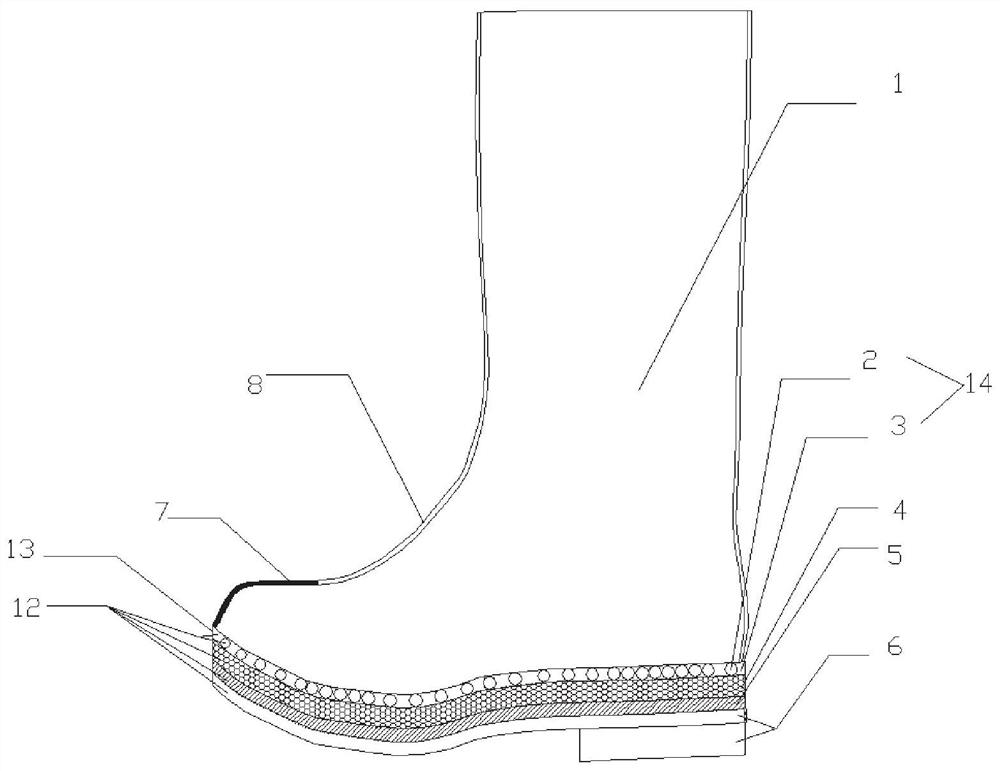

[0060] figure 1 It is a schematic cross-sectional view of an embodiment of the present invention. As shown in the figure, the high-temperature-resistant shock-absorbing anti-puncture work shoes provided by the embodiment of the present invention include: sole 12, vamp 8, boot tube 1, outsole 6, and the inside of sole 12 is provided with anti-puncture layer 5, Aluminum foam interlayer 4, shock-absorbing and energy-absorbing layer 14, a protective structure 7 is provided on the top side of the vamp 8, and a fixed edge 13 is provided on the outside of the vamp 8 and the top of the sole 12;

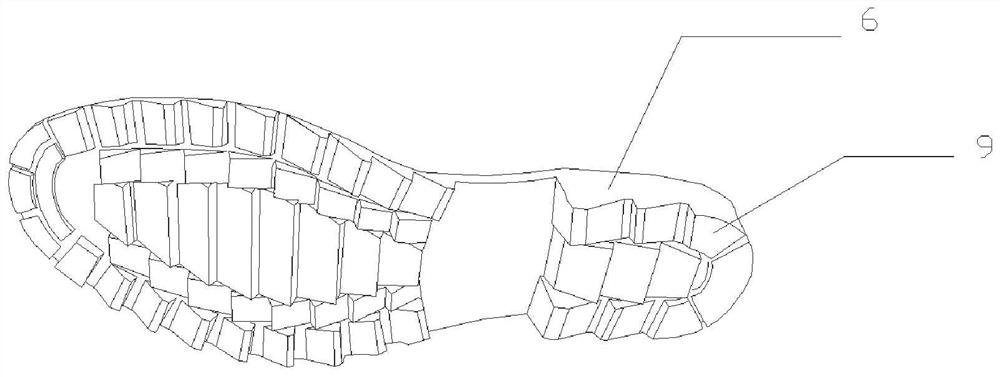

[0061] The sole 12; the inside of the sole 12 is provided with an anti-puncture layer 5, an aluminum foam interlayer 4, and a shock-absorbing energy-absorbing layer 14, and the bottom end of the sole 12 is provided with a pattern 9, and the pattern 9 can be a stepped pattern, a horizontal and vertical pattern, a V-shaped pattern, etc. ,Such as image 3 shown.

[0062] Such as figure 2 As...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap