Fodder raw material crushing processing equipment

A technology of processing equipment and feed raw materials, which is applied in the field of feed raw material crushing and processing equipment, can solve the problems of feed pellets not being recycled, feed crushing particle size is not uniform, and the overall uniformity of pellets is low, so as to improve the screening effect and sieving speed, improve the degree of fineness and pass rate, and improve the effect of grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

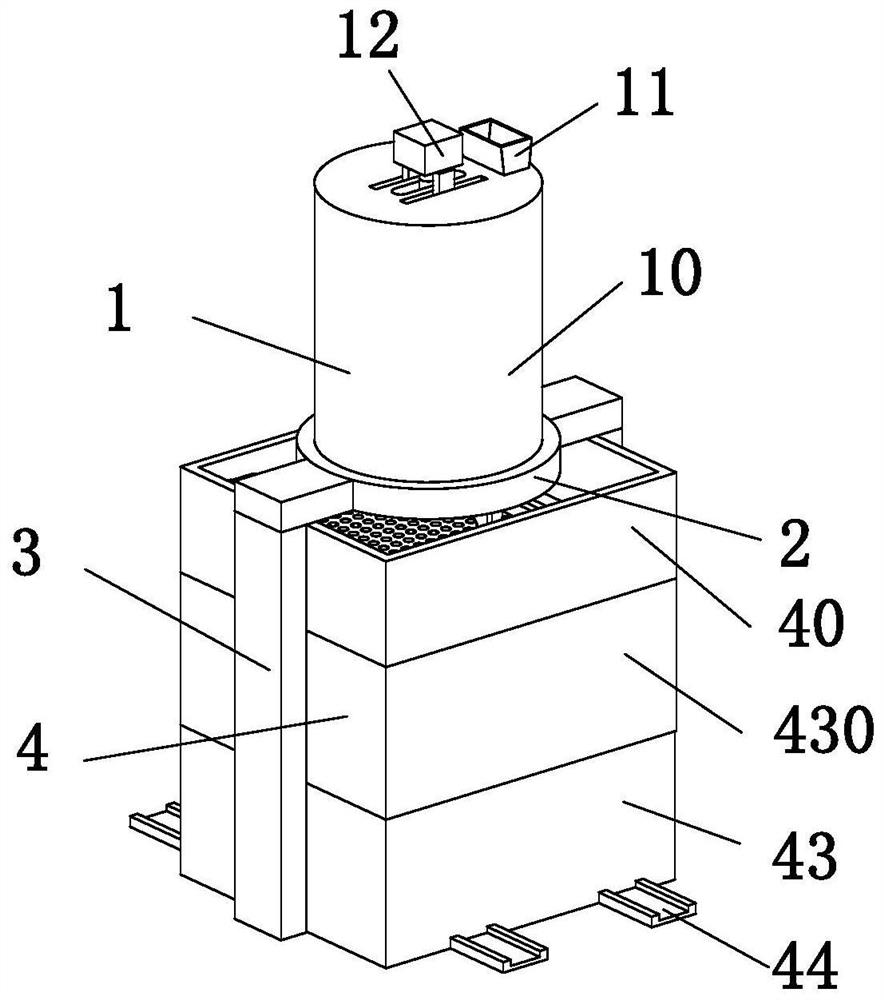

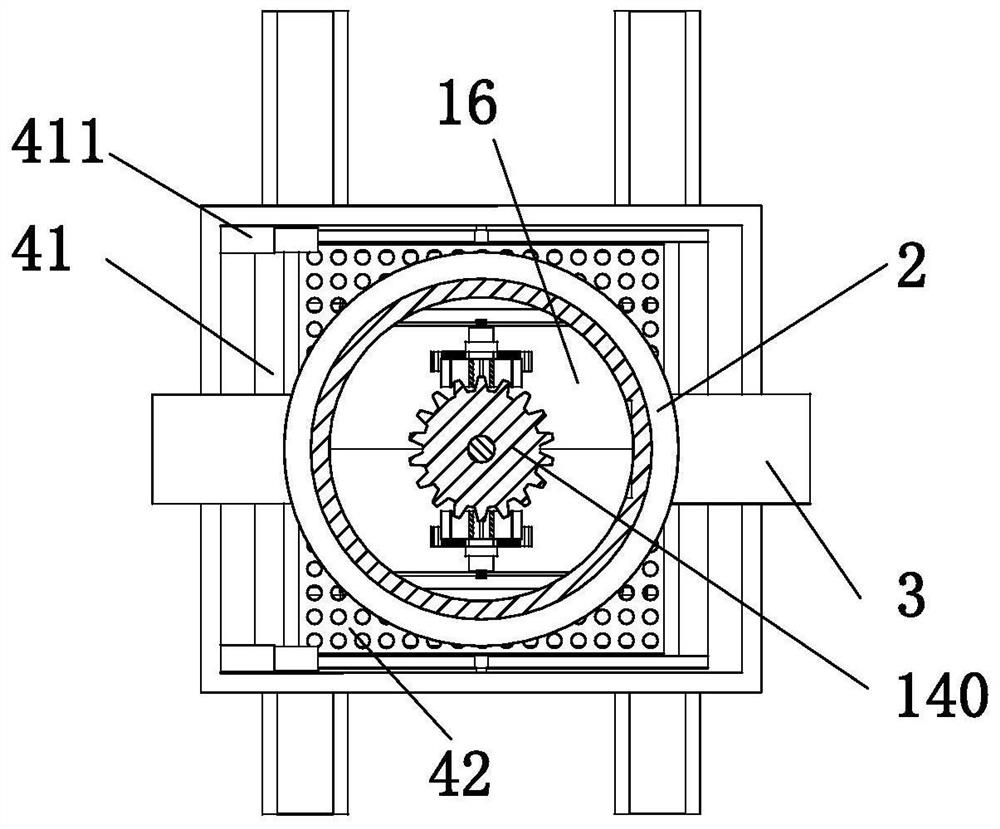

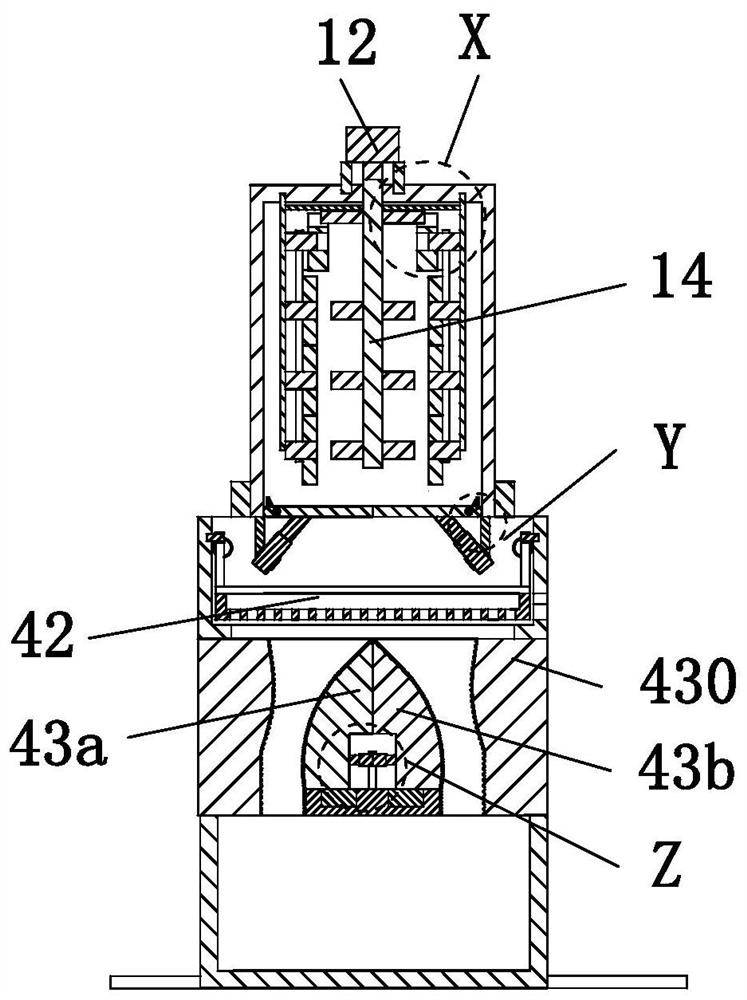

[0031] like Figure 1 to Figure 8 As shown, a feed raw material crushing and processing equipment includes a crushing mechanism 1, a collar 2, a bracket 3 and a material receiving mechanism 4. The lower end of the crushing mechanism 1 is equipped with a collar 2, and the front and rear ends of the collar 2 are symmetrical. Supports 3 are installed, and the lower end between them is installed on the existing working ground, and a material receiving mechanism 4 is arranged between the supports 3 .

[0032] The crushing mechanism 1 includes a mixing bucket 10, a feed channel 11, a motor 12, a No. 1 electric slider 13, a fixed shaft 14, a crushing wheel 15, a semicircular sealing plate 16, a No. 1 electric push rod 17 and a connecting frame 18, The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com