Floor grinding and trimming machine

A technology of trimming machine and grinding mechanism, which is applied in the field of grinding machines, can solve the problems of insufficient grinding, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

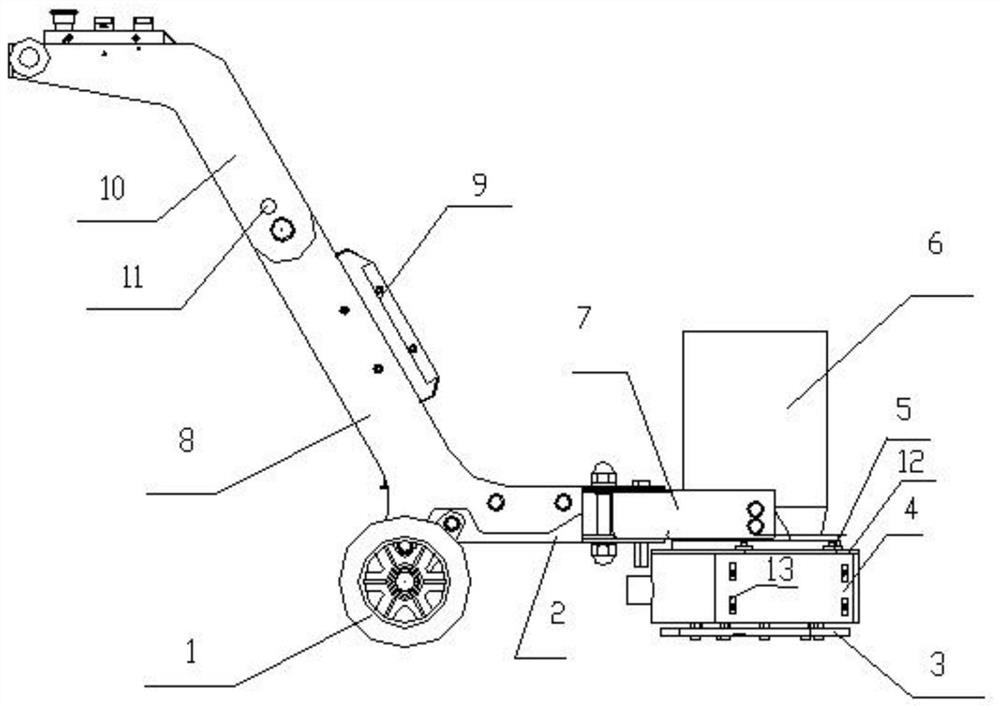

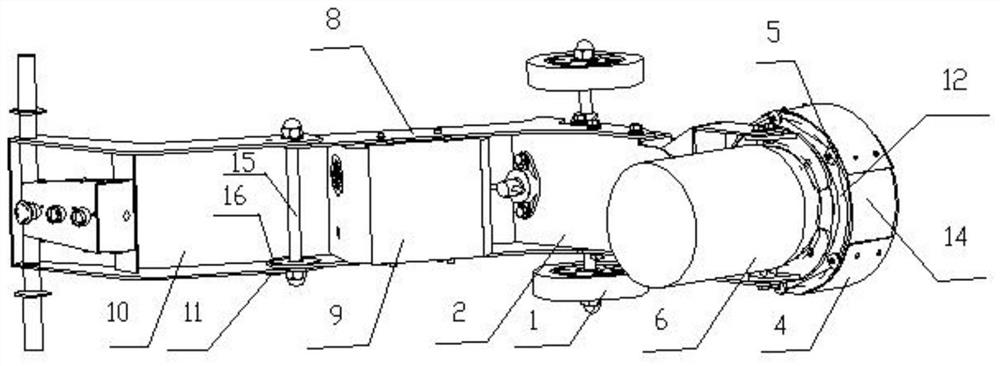

[0016] A ground grinding and trimming machine, which includes a chassis 2 with a traveling wheel 1, a frame 8, a grinding mechanism, a frequency converter 9 and a drive motor 6, the front end of the chassis is hinged with a connecting frame 7, and the grinding mechanism includes a mounting plate 12 and A plurality of grinding sheets 3 are installed on the mounting plate, the mounting plate is mounted on the connecting frame and the side is provided with a mounting plate notch 14, the two can be fixedly connected by bolts, and can also be connected in other ways.

[0017] The notch of the mounting disc is directly opposite to the outer edge of the grinding sheet, and rubber wheels 5 are respectively installed on the two ends of the notch on the mounting disc.

[0018] The drive motor is fixedly mounted on the mounting plate to drive the grinding disc to rotate, the frame is fixedly mounted on the rear of the chassis, the frequency converter is fixedly mounted on the frame and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com