Architectural decoration environmental-protection construction system

An environmental protection and construction technology, applied in the direction of manufacturing tools, ceramic molding machines, molds, etc., can solve the problems of no waste recycling device, stair adjustment, resource waste, etc., to achieve safe and convenient use, reduce resistance, and reduce waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

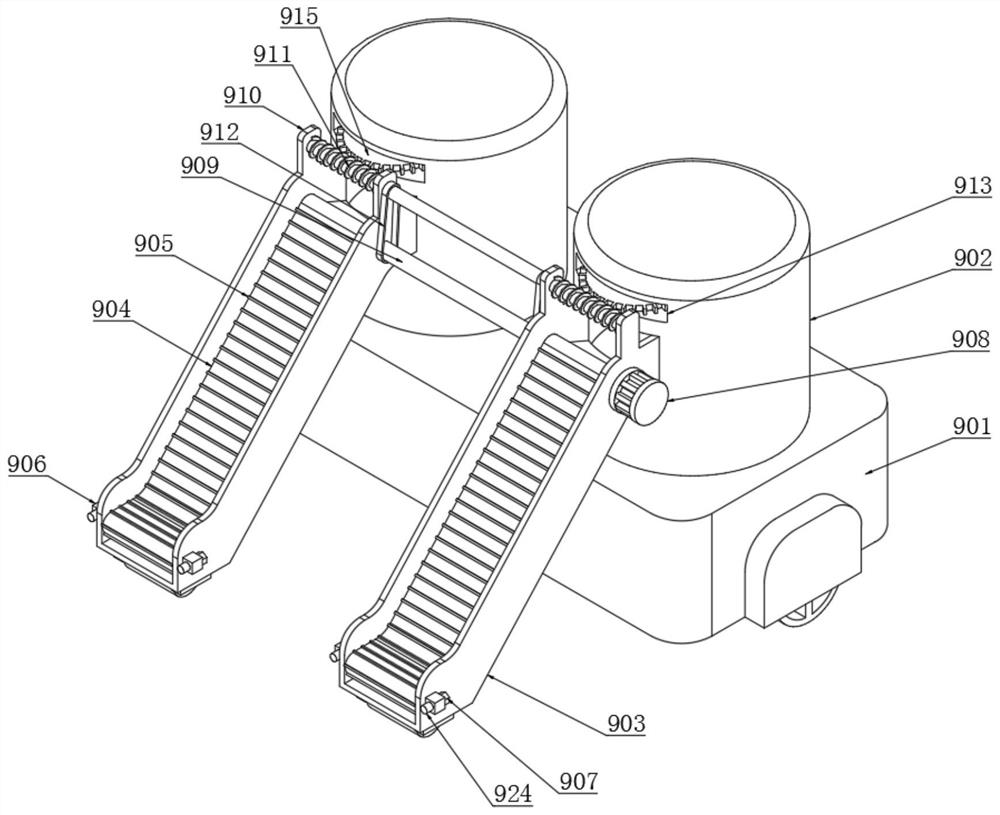

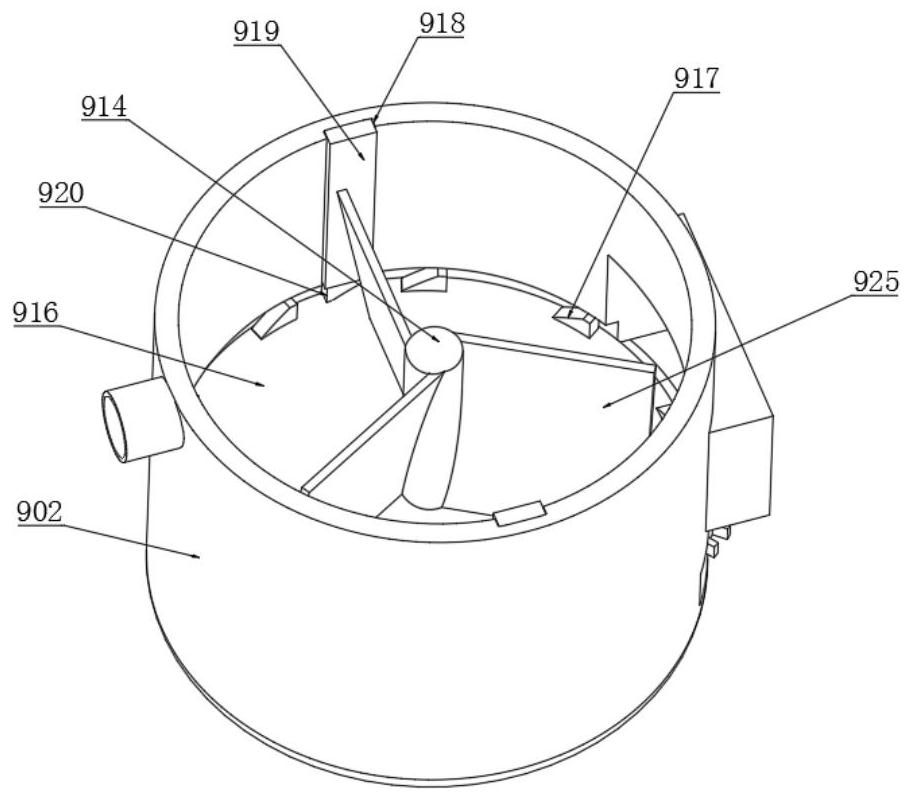

[0049] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, a building decoration environmental protection construction system, including an environmental protection construction device 100 and a separation and recovery device 200. After the construction of the environmental protection construction device 100, the separation and recovery device 200 is used to process the Sorting and recycling waste materials, the separation and recovery device 200 includes a recovery box 20001, a screening cylinder 20002, a feeding channel 20003, a conveyor belt 20004, a material blocking plate 20005, a connecting block 20006, a locking nut 2000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com