Concrete preparing device with screening function

A concrete and functional technology, which is applied in the field of concrete batching devices with screening functions, can solve the problems of increasing labor costs, large errors, and high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

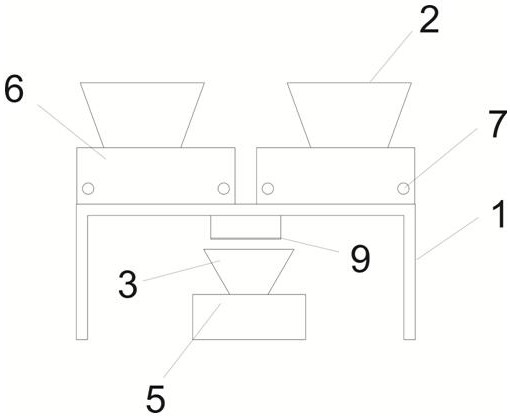

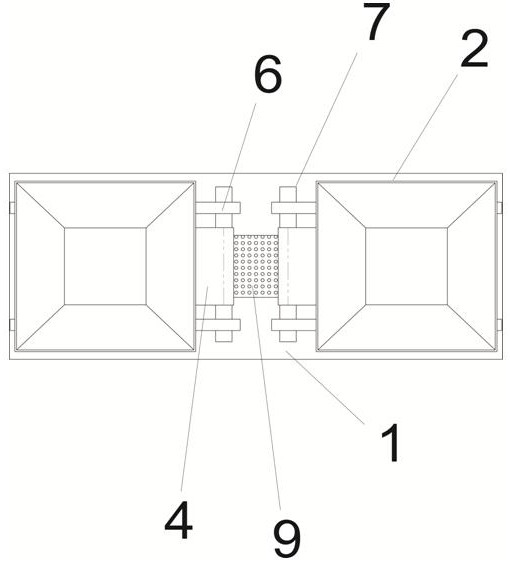

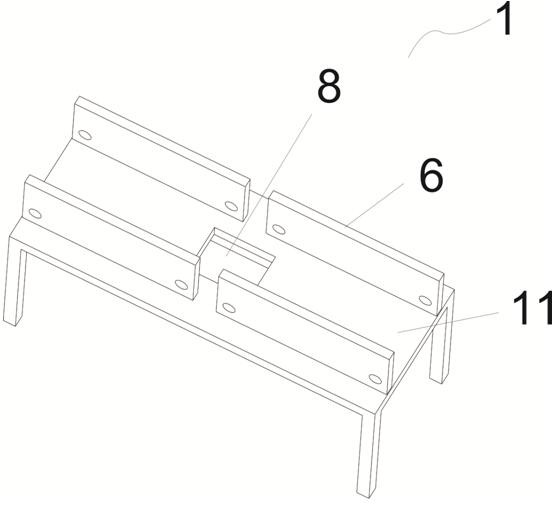

[0024] like Figure 1-3 As shown, this embodiment is a concrete batching device with a screening function, including a bracket 1, a raw material hopper 2, a hopper 3, a conveyor belt 4, a driving device, a sensor and a weighing device 5. The bracket 1 is provided with a working panel 11. , There is a through hole 8 on the work panel 11, a raw material hopper 2 is set above the work panel 11, a conveyor belt 4 is installed between the raw material hopper 2 and the work panel 11, the material in the raw material hopper 2 falls on the conveyor belt 4, and is transported by the conveyor belt 4 To the through hole 8, there is a hopper 3 just below the through hole 8, a weighing device 5 is arranged below the hopper 3, and a filter screen 9 is also installed on the bracket 1 by bolts, and the filter screen 9 is arranged in the through hole. 8 and the hopper 3, and the outline size of the filter screen 9 is larger than the size of the through hole 8.

[0025] The weighing device 5 i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap