Optical glass rod grooving machine

A technology of optical glass and slotting machine, which is applied in the direction of working accessories, stone processing tools, stone processing equipment, etc., and can solve the problems of inability to process optical glass rods and the inability to flexibly adjust the position of the drill bit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

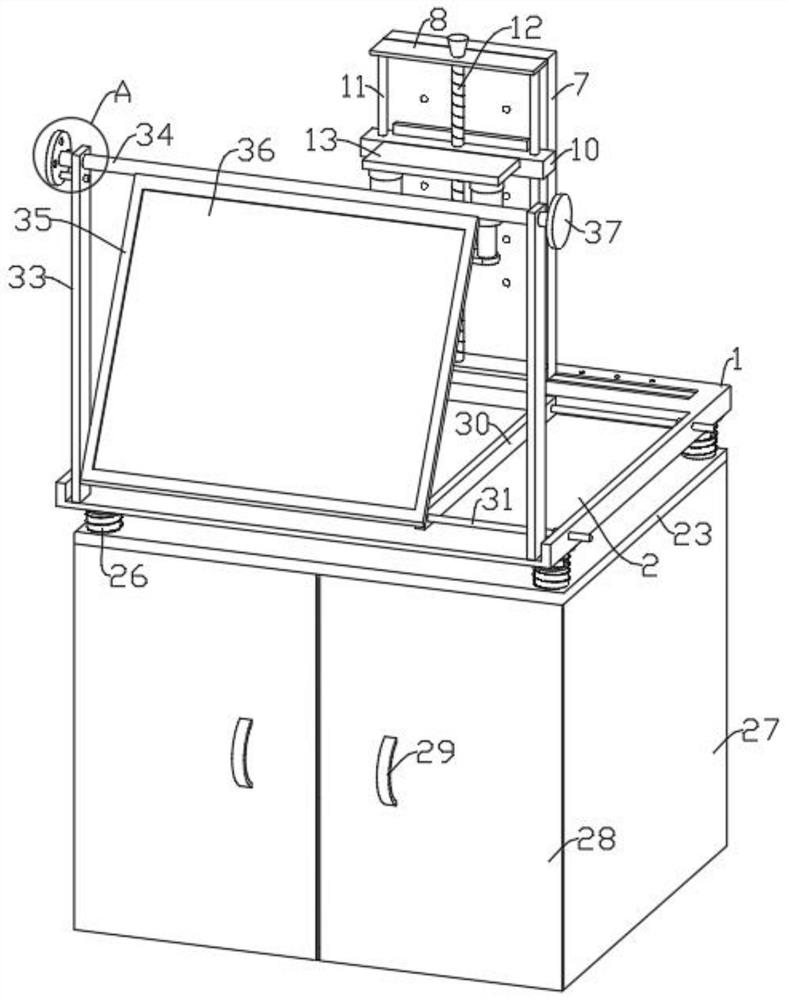

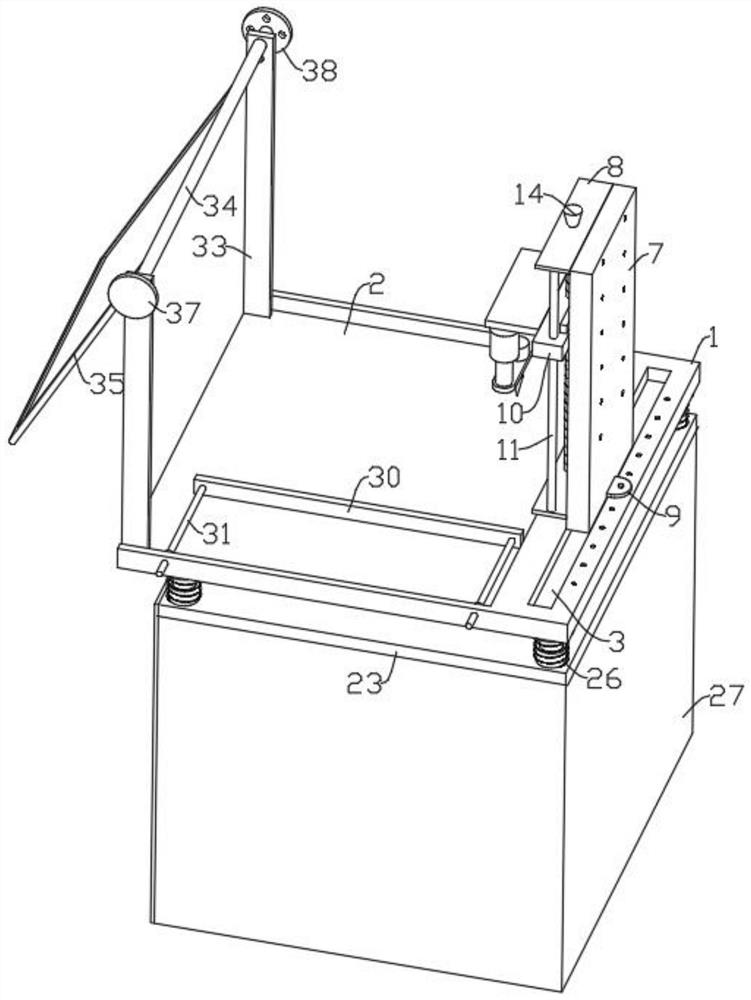

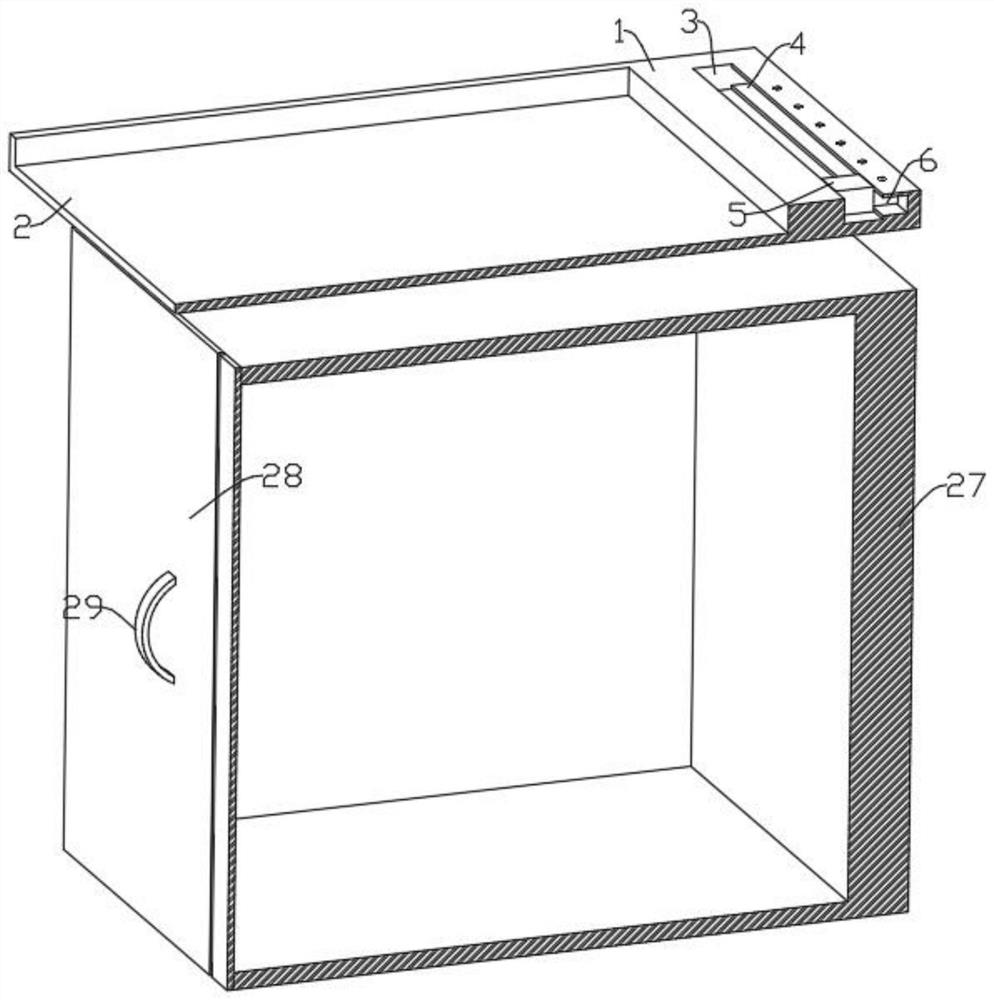

[0023] refer to Figure 1-5 , an optical glass bar stock slotting machine, comprising a base plate 1, a workpiece groove 2 is provided on the top of the base plate 1, a chute 3 is provided on one side of the top of the base plate 1, a card slot 4 is provided on one side of the chute 3, and a chute 3 A slider 5 is provided for sliding inside, and a block 6 is fixedly installed on one side of the slider 5, and the block 6 is slidably arranged in the slot 4, and a vertical beam 7 is fixedly installed on the top of the slider 5, and the lower end of one side of the vertical beam 7 is fixedly installed There is a connecting piece 9, and a plurality of threaded holes are provided on the base plate 1, and the connecting piece 9 is connected with the base plate 1 through screws, and horizontal plates 8 are fixedly installed at the upper and lower ends of one side of the vertical beam 7, respectively. The movable seat 10 is provided with guide rods 11 between the two horizontal plates ...

Embodiment 2

[0026] refer to Figure 1-5 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that a backing plate 23 is provided at the bottom of the bottom plate 1, and a shock absorbing mechanism is provided at the four corners of the top of the backing plate 23, and the shock absorbing mechanism includes a sleeve 24 , the sleeve 24 is fixedly installed on the top of the backing plate 23, the inner column 25 is inserted in the sleeve 24, the sleeve 24 and the inner column 25 are covered with a spring 26, and the upper and lower ends of the spring 26 are respectively fixed to the bottom plate 1 and the backing plate 23 To connect, by setting a shock-absorbing mechanism, the shock-absorbing property of the spring 26 is used to slow down the vibration generated when the motor 20 is working, so that the slotting drill bit 19 is not easy to vibrate when it is working, and the precision of slotting is improved.

[0027] Backing plate 23 bottoms recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com