Multicolor packaging bottle cap forming device and process thereof

A molding device and molding process technology are applied in the field of multi-color packaging bottle cap molding devices to achieve the effects of uniform color, bright overall color and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

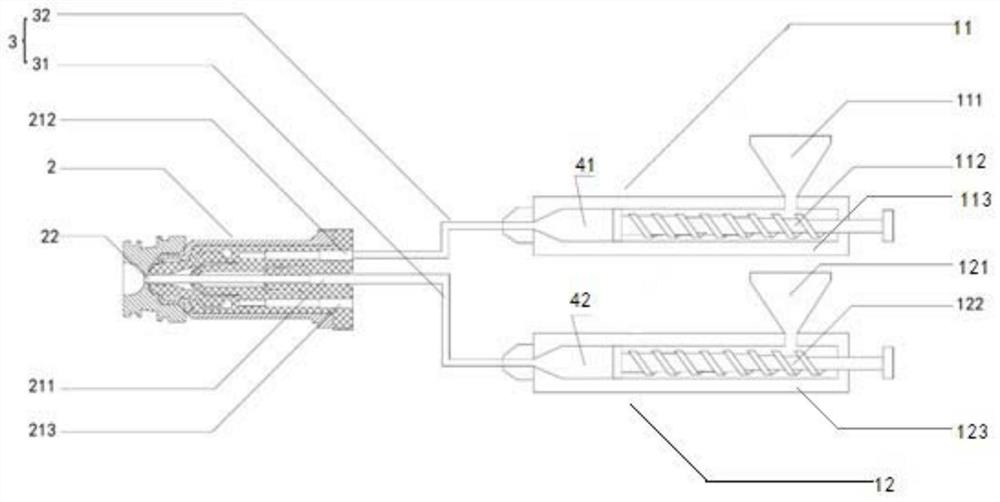

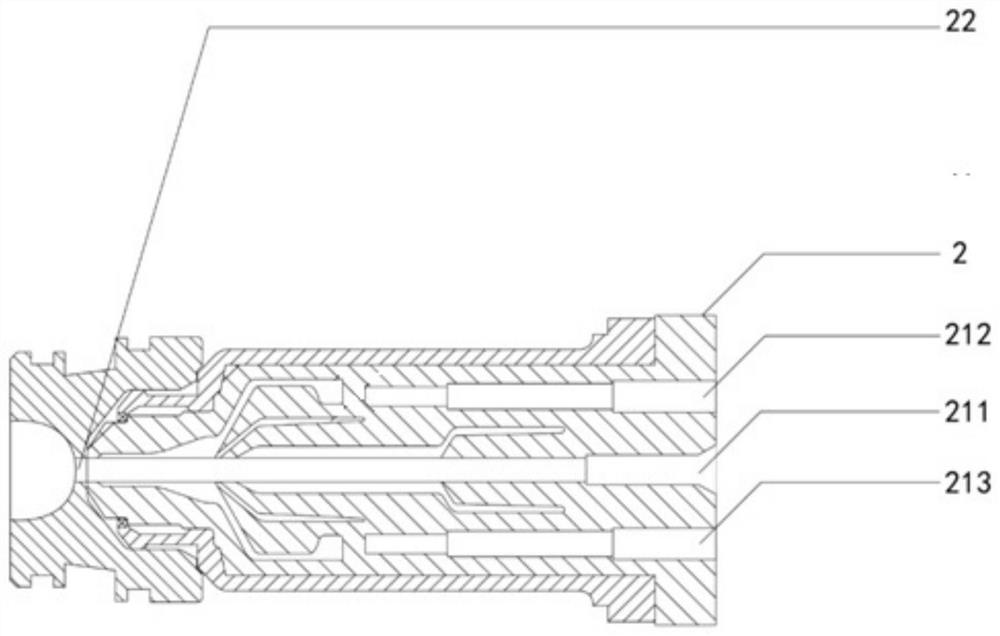

[0035] like Figures 1 to 2 As shown, this embodiment provides a multi-color sealing bottle cap forming device, including several screw reciprocating plasticizing injection devices filled with different materials, an injection nozzle 2 and a conduit 3 . In this embodiment, the number of screw reciprocating plasticizing injection devices is two, which are the first screw reciprocating plasticizing injection device 11 and the second screw reciprocating plasticizing injection device 12; the first screw reciprocating plasticizing injection device 11 includes a first hopper 111, a first screw 112, a first barrel 113, the first hopper 111 is arranged on the first barrel 113, and is used as a feeding port; the first barrel 113 is provided with a first screw 112, The first screw 112 is in clearance fit with the first barrel 113 . A driving device is connected to the first screw 112, which can drive the screw to rotate and extrude. In this embodiment, the driving device is preferably ...

Embodiment 2

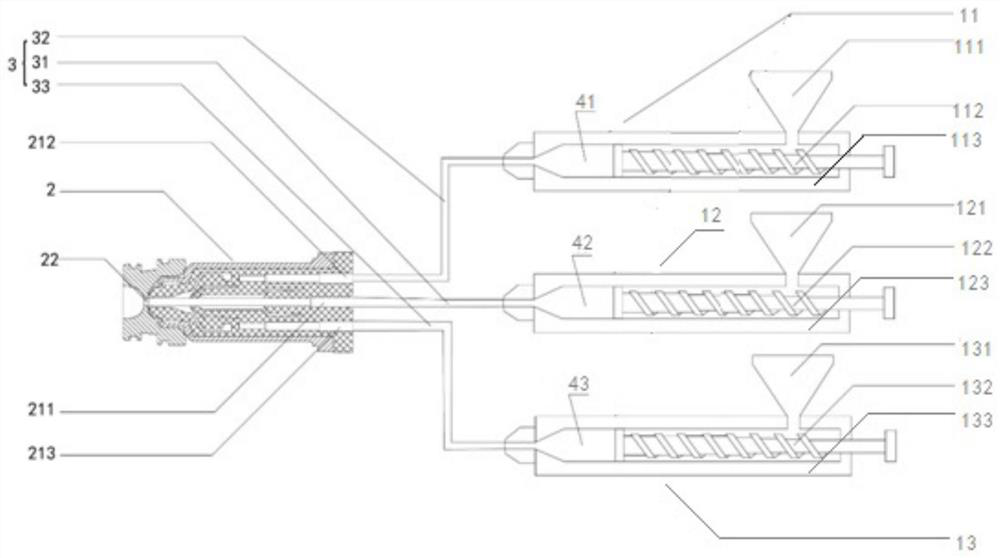

[0040] like image 3 As shown, this embodiment refers to Embodiment 1, and provides a multi-color sealing bottle cap molding device. The difference from Embodiment 1 is that in this embodiment, a third screw reciprocating plasticizing injection device 13 is also provided. , including the third hopper 131, the third screw 132, the third barrel 133, the third material 43 is installed in the third screw reciprocating plasticizing injection device 13, and the third material 43 passes through the third conduit 33 and the injection nozzle 2. The access port 213 is connected and merged at the injection end 22 ; the structure of the third screw reciprocating plasticizing injection device 13 is consistent with the working process and the first screw reciprocating plasticizing injection device 11 .

Embodiment 3

[0042] like Figure 4 As shown, this embodiment refers to Embodiment 1, and provides a multi-color sealing bottle cap forming device, which is different from Embodiment 1 in that a plurality of injection nozzles 2 are provided in this embodiment. According to the present invention, the number of corresponding injection nozzles can be set according to the number of injection cavities on the injection mold, so as to complete the injection molding work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com