Processing method of inorganic copper preparation

A processing method and inorganic copper technology, applied in botany equipment and methods, chemicals for biological control, biocides, etc., can solve problems such as prone to phytotoxicity, uneven particle size distribution, and poor mixing of liquid medicines , to achieve the effect of improving equipment utilization rate and production efficiency, improving mixing suitability, and meeting market supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

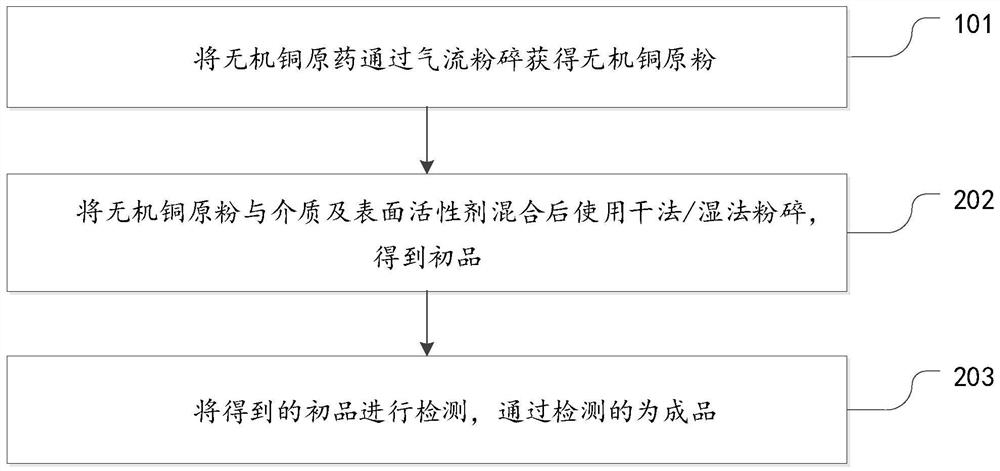

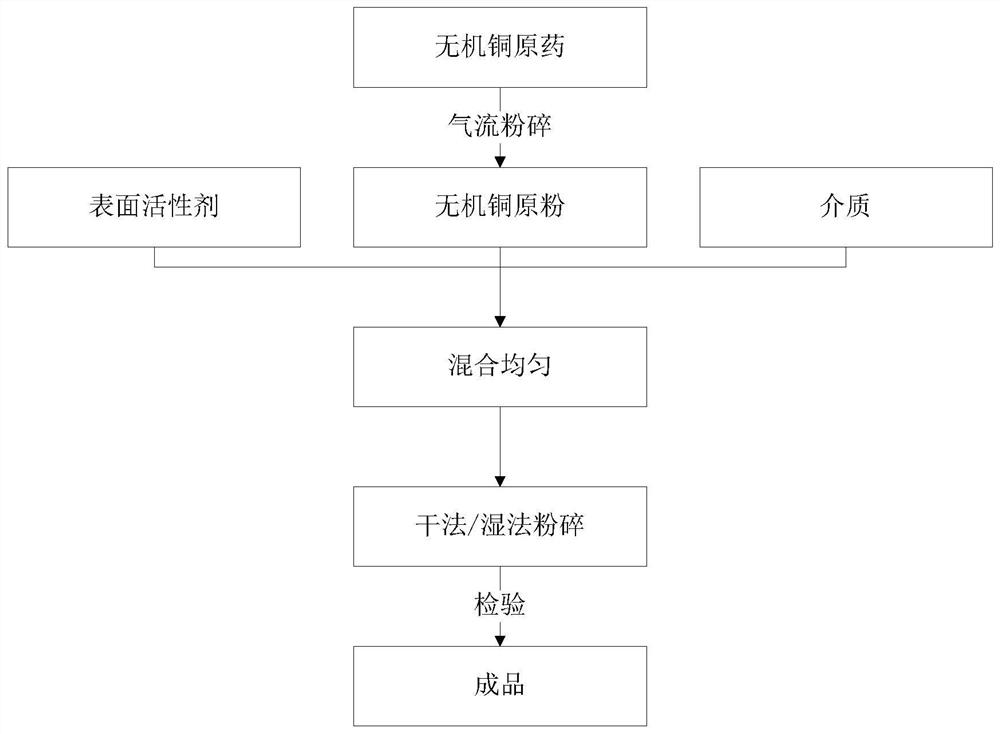

Method used

Image

Examples

Embodiment 1

[0031] 1. Production of 50% king copper wettable powder

[0032] Take 98% of the original copper king, adopt 600 type jet crushing, control the crushed king copper powder D97 to be less than 25 microns, and obtain 98% king copper powder after collection;

[0033] Select 98% king copper former powder 510Kg and tensio-active agent D8818 40Kg, WLNOK-K 40Kg, white carbon black 30Kg, kaolin 380Kg, through airflow pulverization after fully uniform mixing, control particle diameter D97 to be less than 10 microns, obtain finished product; The analysis of the finished product shows that the suspension rate reaches 93%, and it has better compatibility with other preparations; the pulverization time is narrower than that of the original one-step method to obtain the same particle size powder, and the pulverization time can be shortened by more than half.

Embodiment 2

[0035] 2. Production of 30% King Copper Water Suspension Concentrate

[0036] Get 98% king copper former medicine, adopt 600 type jet milling, the king copper former powder D97 after controlling pulverization is less than 25 microns, obtain 98% king copper former powder after collecting;

[0037] Select 310Kg of 98% king copper raw powder, 40Kg of surfactant FS3000, 1g of magnesium aluminum silicate, 2Kg of xanthan gum, 50Kg of ethylene glycol, 2Kg of defoamer, 2Kg of preservative, and 584Kg of deionized water. Wet pulverization of the mill, the particle size D97 is controlled to be less than 4 microns, and the finished product is obtained; after the analysis of the finished product, the suspension rate reaches 98%, and the compatibility with other preparations is better; the pulverization time is longer than that of the original one-step method to obtain the same particle size The diameter powder distribution is narrower, and the crushing time can be shortened by more than ha...

Embodiment 3

[0039] 3. Production of 86.2% cuprous oxide wettable powder

[0040] Take 98% cuprous oxide former medicine, adopt 600 type jet milling, control the king copper former powder D97 after pulverizing to be less than 15 microns, obtain 98% cuprous oxide former powder after collecting;

[0041] Select 98% cuprous oxide raw powder 880Kg and surfactant D8818 40Kg, WLNOK-K 40Kg, white carbon black 30Kg, kaolin 10Kg, after fully and evenly mixed, through jet pulverization, control particle diameter D97 to be less than 5 microns, obtain finished product; The analysis of the finished product shows that the suspension rate reaches 90%, and it has better compatibility with other preparations; the pulverization time is narrower than that of the original one-step method to obtain the same particle size powder, and the pulverization time can be shortened by more than half.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com