Quick normal temperature pouring device based on SLA photocuring technique and method thereof

A light-curing and light-curing molding technology, applied in the field of mold manufacturing, can solve the problems of high cost and time-consuming small batch manufacturing, and achieve the effects of short production cycle, low processing cost and accurate manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

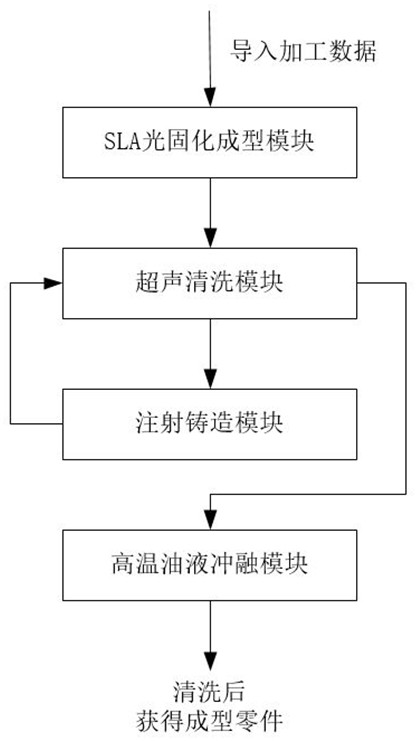

Method used

Image

Examples

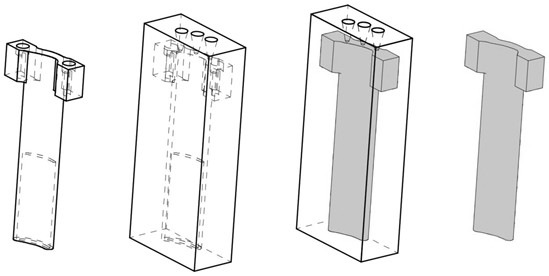

Embodiment 1

[0021] (1) Establish a three-dimensional model of the part 1 on the computer, design the containing casting cavity 1 according to the three-dimensional model, and design three tapered holes for injection casting on the top of the cavity 1; model the cavity 1 Format conversion, slicing processing, and generation of processing data that can be photocured and printed;

[0022] (2) According to the performance requirements of the parts, select EP2115 epoxy high-temperature adhesive (melting point 180°C, optimal solidification temperature 60°C) as the casting material, and correspondingly select 8200 photosensitive resin (melting point 80°C) and pour it into the liquid tank of the SLA light curing machine , import the processing data, and start printing the containing casting cavity 1;

[0023] (3) Put the formed resin cavity 1 into an ultrasonic cleaner, use 30% alcohol for ultrasonic cleaning, and degas for 15 minutes. After completely removing the excess uncured resin inside and...

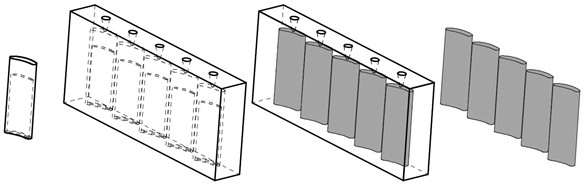

Embodiment 2

[0029] (1) Establish a three-dimensional model of part 2 on the computer, array 5 models of part 2, design the containing casting cavity 2 according to the model group of the array, and design 5 tapered holes for injection casting on the top of the cavity 2 ; Perform model format conversion and slicing processing on the cavity body 2 to generate photocurable and printable processing data 2;

[0030] (2) According to the performance of the parts, select Chemlok 218 castable polyurethane thermal vulcanizate (melting point 120°C, optimal solidification temperature 40°C) as the pouring material, select 8000 photosensitive resin (melting point 50°C) and pour it into the SLA light curing machine In the liquid tank, import the processing data, and start printing the cavity 2 containing the casting mold;

[0031] (3) Put the formed resin cavity 2 into an ultrasonic cleaner, use 30% alcohol for ultrasonic cleaning, and degas for 30 minutes. After completely removing the excess uncured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com