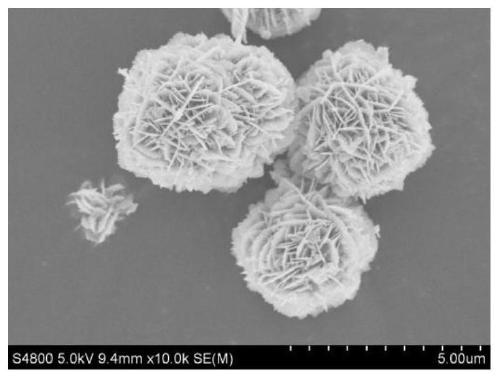

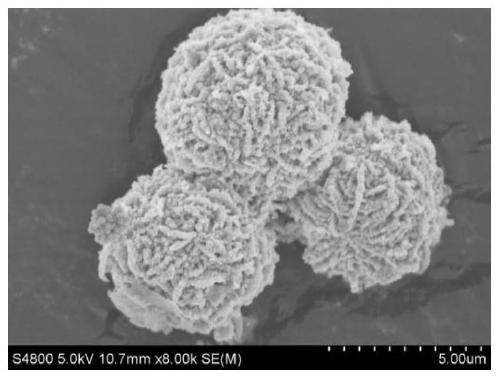

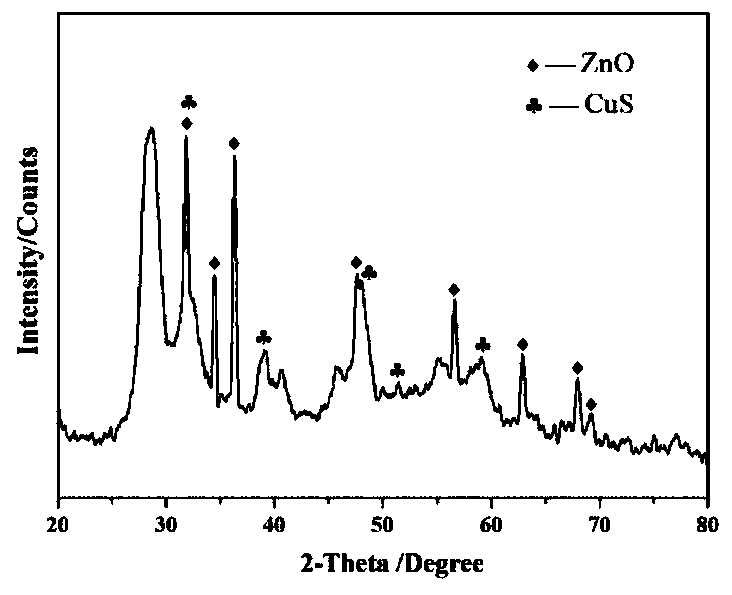

Hydrangea-like zinc oxide@copper sulfide and preparation method thereof

A hydrangea and zinc oxide technology, applied in the direction of zinc oxide/zinc hydroxide, copper sulfide, etc., can solve the problems of less appearance, harsh reaction conditions, and complicated operation steps, and achieve the effect of uniform size and regular appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A method for preparing hydrangea-shaped zinc oxide@copper sulfide, comprising the following steps:

[0033] Step 1: Dissolve the zinc source and sodium citrate in deionized water at room temperature, and stir to form a colorless and transparent solution; then, add 60-80 mL of aqueous sodium hydroxide solution to make the pH of the system to 11-13, After forming a uniform milky white solution, stir and react at room temperature for 2-4 hours, centrifuge and dry to obtain hydrangea-shaped zinc oxide. The ratio of zinc source, sodium citrate and deionized water is (5.0-7.0) mmoL: (7.0-21.0) mmoL: (55-65) mL.

[0034] Step 2: ultrasonically disperse the hydrangea-shaped zinc oxide prepared in step 1 in isopropanol to form a stable suspension; then, add an aqueous solution of sodium sulfide nonahydrate to the suspension and stir at room temperature for 2 to 4 hours; Finally, add the isopropanol solution of copper chloride dihydrate into the system and continue to stir and r...

Embodiment 1

[0042]Step 1: at room temperature, dissolve 6.0mmoL of zinc acetate dihydrate and 15mmoL of sodium citrate in 55mL of deionized water, stir to form a colorless and transparent solution; then, add 72mL of sodium hydroxide aqueous solution (concentration 0.7 mol / L) to make the pH of the system to 11, form a uniform milky white solution, stir and react at room temperature for 2 hours, centrifuge, and dry to obtain hydrangea-shaped zinc oxide.

[0043] Step 2: ultrasonically disperse 0.3 g of hydrangea-shaped zinc oxide prepared in step 1 in 50 mL of isopropanol (ultrasonic power is 300 W, ultrasonic frequency is 45 KHz), and after 10 min, it is formed into a stable suspension; then, the 50mL of sodium sulfide nonahydrate aqueous solution (concentration: 0.05mol / L) was added to the suspension and stirred at room temperature for 2h; finally, 54mL isopropanol solution of copper chloride dihydrate (concentration: 0.05mol / L) was added to the system Continue to stir and react at room t...

Embodiment 2

[0047] Step 1: at room temperature, dissolve 5.0mmoL of zinc acetate dihydrate and 7.0mmoL of sodium citrate in 60mL of deionized water, stir to form a colorless and transparent solution; then, add 75mL of aqueous sodium hydroxide ( The concentration is 0.6 mol / L) to bring the pH value of the system to 12, form a uniform milky white solution, stir and react at room temperature for 2 hours, centrifuge and dry to obtain hydrangea-shaped zinc oxide.

[0048] Step 2: ultrasonically disperse 0.2 g of the hydrangea-like zinc oxide prepared in step 1 in 40 mL of isopropanol (ultrasonic power is 250 W, ultrasonic frequency is 50 KHz), and after 15 min, it is formed into a stable suspension; then, the 52mL aqueous solution of sodium sulfide nonahydrate (concentration: 0.03mol / L) was added to the suspension and stirred at room temperature for 3 hours; finally, 50mL isopropanol solution of copper chloride dihydrate (concentration: 0.045mol / L) was added to the system to continue Stir and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com