Quartz panel and preparation method thereof

A quartz and plate technology, applied in the field of quartz plate and its preparation, can solve the problems of decreased strength and high use cost, and achieve the effects of improving bonding performance, providing strength and improving overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

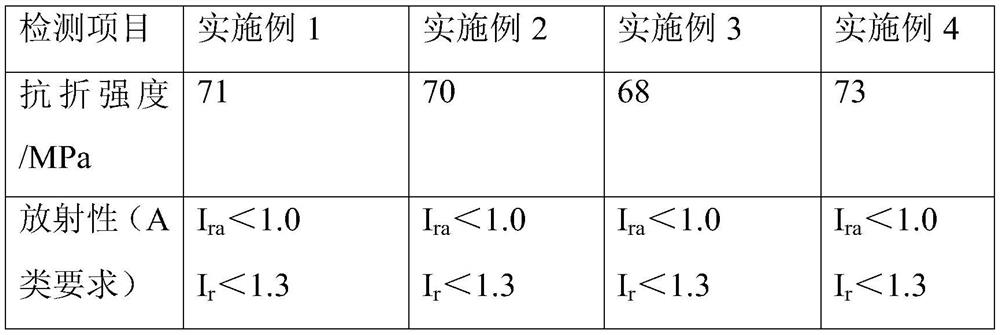

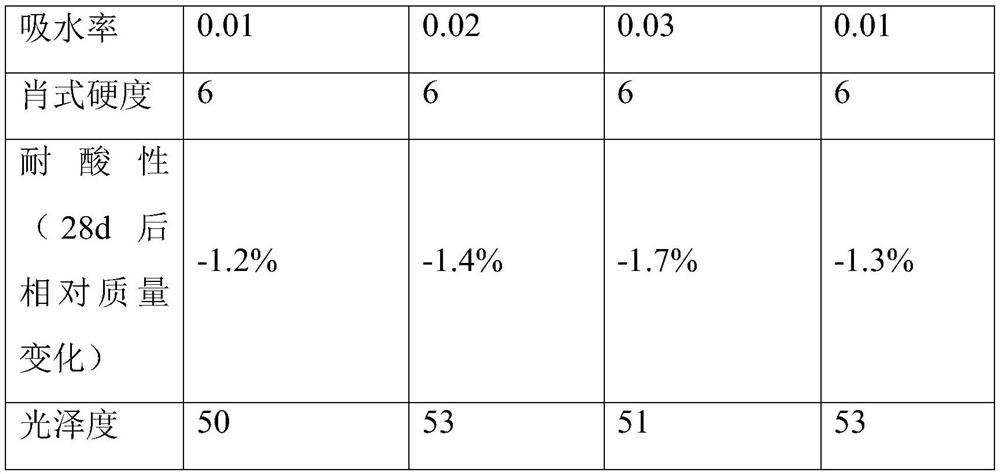

Examples

Embodiment 1

[0027] The quartz plate material comprises the following components in parts by mass: 700 parts of quartz mixture, 100 parts of binder, 80 parts of glass powder, and 30 parts of toner.

[0028] Wherein, the quartz mixture includes the following components in parts by mass: 70-mesh quartz powder, 40-mesh quartz powder, 26-mesh quartz powder, and 16-mesh quartz powder.

[0029] The glass powder includes the following components in parts by mass: a 16-mesh gray-backed mirror, an 8-mesh white glass, and a 6-mesh double-sided mirror.

[0030] The adhesive includes the following components in parts by mass: 20 parts of dicyclopentenyl methacrylate, 16 parts of polysulfone resin, 18 parts of acrylic resin, 7 parts of calcium palmitate, bismaleimide 6 parts of amine.

[0031] The preparation method of quartz plate comprises the steps:

[0032] Step 1. Modified quartz mixture

[0033] In terms of parts by mass, the mixed quartz powder is modified to obtain modified quartz powder;

...

Embodiment 2

[0043] The quartz plate comprises the following components in parts by mass: 710 parts of quartz mixture, 110 parts of binder, 90 parts of glass powder, and 40 parts of toner.

[0044] Wherein, the quartz mixture includes the following components in parts by mass: 80-mesh quartz powder, 50-mesh quartz powder, 30-mesh quartz powder, and 20-mesh quartz powder.

[0045] The glass powder includes the following components in parts by mass: 20-mesh gray-backed mirror, 10-mesh white glass, and 7-mesh double-sided mirror.

[0046] The adhesive includes the following components in parts by mass: 21 parts of dicyclopentenyl methacrylate, 17 parts of polysulfone resin, 20 parts of acrylic resin, 8 parts of calcium palmitate, bismaleimide 7 parts of amine.

[0047] The preparation method of quartz plate comprises the steps:

[0048] Step 1. Modified quartz mixture

[0049] In terms of parts by mass, the mixed quartz powder is modified to obtain modified quartz powder;

[0050] Modifie...

Embodiment 3

[0059] The quartz plate comprises the following components in terms of parts by mass: 720 parts of quartz mixture, 120 parts of binder, 90 parts of glass powder, and 45 parts of toner.

[0060] Wherein, the quartz mixture includes the following components in parts by mass: 100-mesh quartz powder, 60-mesh quartz powder, 40-mesh quartz powder, and 20-mesh quartz powder.

[0061] The glass powder includes the following components in parts by mass: a 25-mesh gray-backed mirror, a 10-mesh white glass, and an 8-mesh double-sided mirror.

[0062] The adhesive includes the following components in parts by mass: 25 parts of dicyclopentenyl methacrylate, 17 parts of polysulfone resin, 22 parts of acrylic resin, 7 parts of calcium palmitate, bismaleimide 7 parts of amine.

[0063] The preparation method of quartz plate comprises the steps:

[0064] Step 1. Modified quartz mixture

[0065] In terms of parts by mass, the mixed quartz powder is modified to obtain modified quartz powder; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com