Anti-Mite Unit Dose Products

A technology for unit dosage and products, which is applied in the field of unit dosage products, and can solve problems such as the influence of film plasticization characteristics, changing the rheological characteristics of liquid laundry detergent compositions, etc.

Active Publication Date: 2022-05-31

PROCTER & GAMBLE CO

View PDF11 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009] However, it is challenging to formulate anti-mite actives into liquid laundry detergent compositions in water-soluble unit dose formulations

First, the presence of such anti-mite actives can alter the rheological properties of liquid laundry detergent compositions and lead to more membrane seal failure events caused by liquid stringing during the manufacturing process

Furthermore, the incorporation of such anti-mite actives into liquid laundry detergent compositions can also result in a greater impact on the plasticizing properties of the film

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

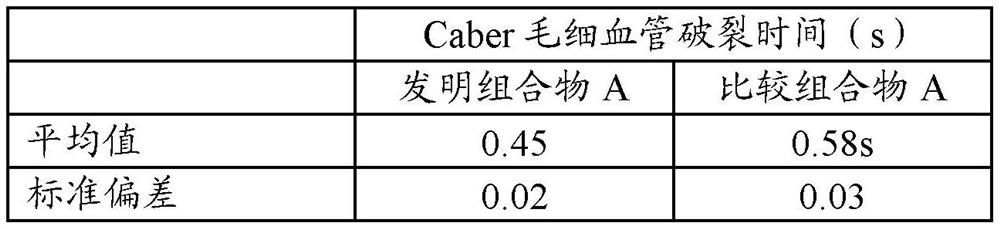

[0093] Liquid drawing

[0095]

[0098]

[0101]

[0103]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Login to View More

Abstract

The present invention is entitled "Anti-mite unit dose preparation". The present invention provides an anti-mite unit dose article comprising a water soluble polymer film formed into a pouch having an internal compartment enclosing a liquid laundry detergent composition therein , and the liquid laundry detergent composition is characterized in that, in 1000s ‑1 A shear rate and a high shear viscosity in the range of 100 mPa·s to 900 mPa·s measured at a temperature of 20° C., and wherein the liquid laundry detergent composition comprises a total weight of the liquid laundry detergent composition 20% to 70% of one or more non-soap surfactants and 1% to 20% of benzyl benzoate. The presence of benzyl benzoate in this amount in the unit dose product not only provides an anti-mite benefit, but also reduces liquid stringing that can lead to membrane seal failure during the manufacturing process of such unit dose products without damaging the membrane. Plasticizing properties are negatively affected.

Description

Anti-Mite Unit Dose Products technical field [0001] The present invention relates to a unit-dose article comprising a water-soluble polymer film formed into a Being a pouch having an inner compartment that encloses the liquid laundry detergent composition therein. Background technique Water-soluble unit dose preparations are becoming increasingly popular among consumers because of their ease of use and reduced Fewer accidental spills during detergent dosing in washing operations. Such water-soluble unit dose preparations typically contain a water-soluble film, the water-soluble film is preferably formed of a polyvinyl alcohol homopolymer, a polyvinyl alcohol copolymer, or a mixture thereof, the water The dissolving film is formed as a pouch containing an interior compartment that encapsulates the liquid laundry detergent composition. [0003] During manufacture of the above-described unit-dose article, the first film is deformed in the mold to form the open cavity, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C11D10/04C11D1/83C11D3/20C11D3/48C11D17/04

CPCC11D10/04C11D10/042C11D10/045C11D1/83C11D3/2093C11D3/48C11D17/043C11D1/72C11D1/29C11D1/22C11D2111/12

Inventor 塞尔吉奥·罗德里格斯罗德里格斯克里夫·艾伯特·韦尔默朗埃尔斯·斯莱文盐道靖子大谷良平R·博莱赫R·R·F·凯勒斯

Owner PROCTER & GAMBLE CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com