Armored vehicle door lock structure

A door lock structure and armored car technology, applied in the field of locks, can solve problems such as flushing, door deformation, etc., and achieve the effects of improving performance, avoiding shaking, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

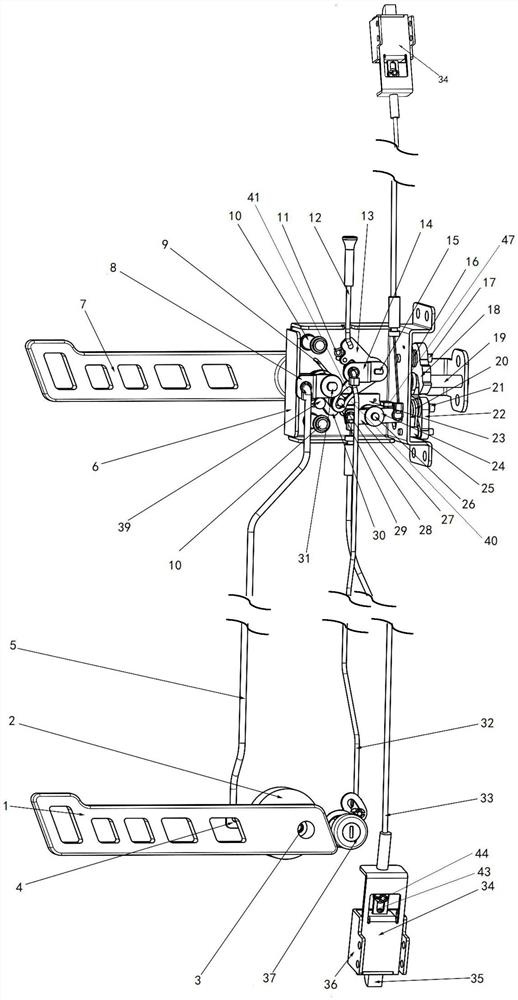

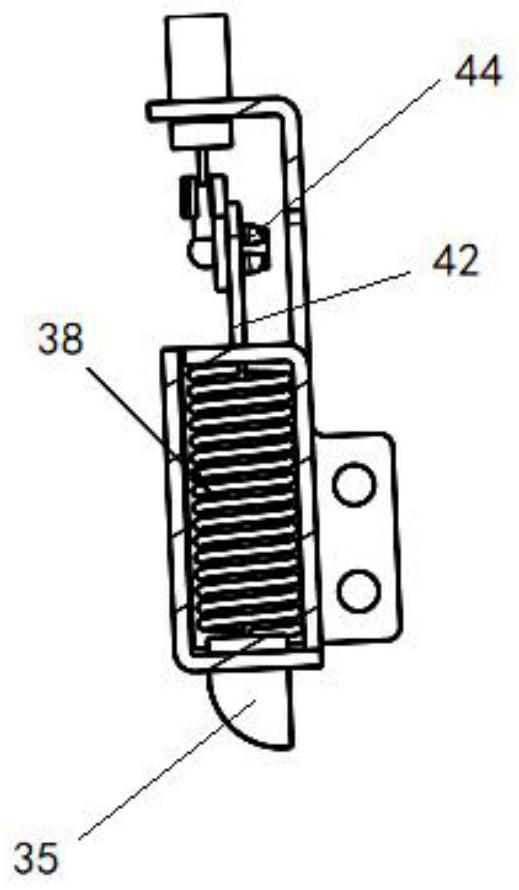

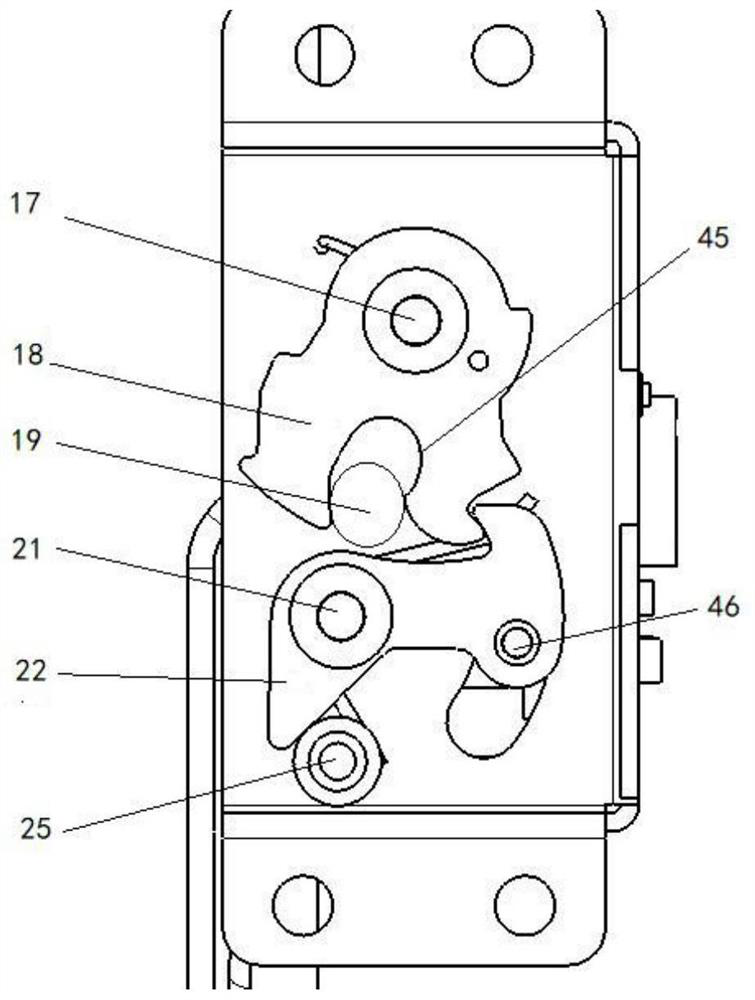

[0071] according to Figure 1~3, the embodiment of the present invention provides a door lock structure for an armored vehicle, including a lock body plate 6, one side of the lock body plate 6 is provided with an outwardly opening linkage arm rotation shaft 31, and the outwardly opening linkage arm rotation shaft 31 and the lock body plate 6 The outer opening return spring 9 is fixed, and the opening rocker arm 30 is fixed on the outer opening linkage arm rotating shaft 31. The end of the opening rocking arm 30 is fixed to lock the linkage shaft 28. The opening rocking arm 30 is V-shaped, and its left end is fixed on the outer opening. Linkage arm rotating shaft 31, its right-hand side is provided with locking linkage shaft 28; The other side on the lock body plate 6 is provided with outwardly opening conversion arm rotating shaft 26, is fixed with outwardly opening conversion arm 23 on the outwardly opening conversion arm rotating shaft 26, outwardly A gasket 24 is provided a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com