Gravel packing device and method for oil layer sand control

A gravel filling and oil layer technology, which is applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problems of unfavorable oil production process, large sand blasting displacement, poor sand control effect, etc., and achieves convenient oil production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

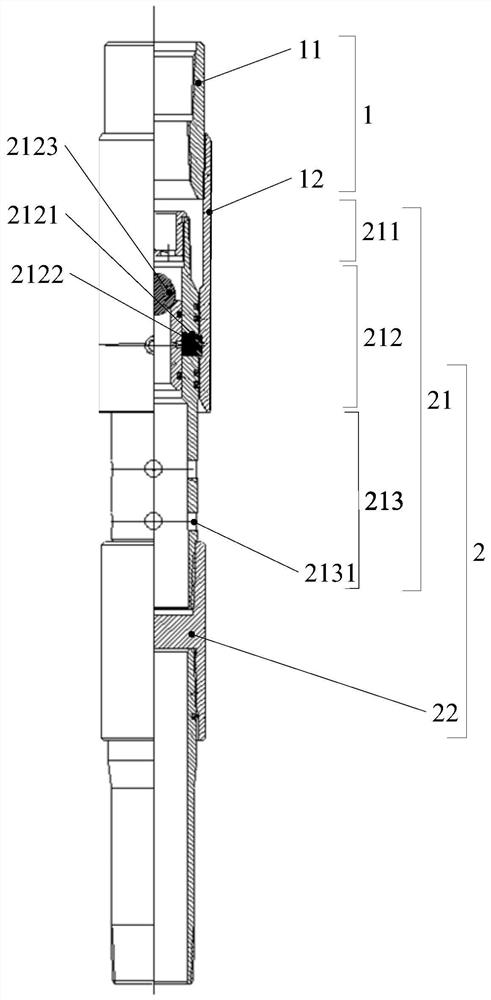

[0055] Lost hands:

[0060] Backwash:

[0064] This step is used to salvage the backwash unit 2 to the well for subsequent oil production. The salvage process can be:

[0066] After the above steps, the device completes the gravel-packing operation, and does not remain in the well after completing the operation,

[0069] In a possible design, the top inner wall of the upper joint 11 has a locking structure for connecting the oil pipe. in,

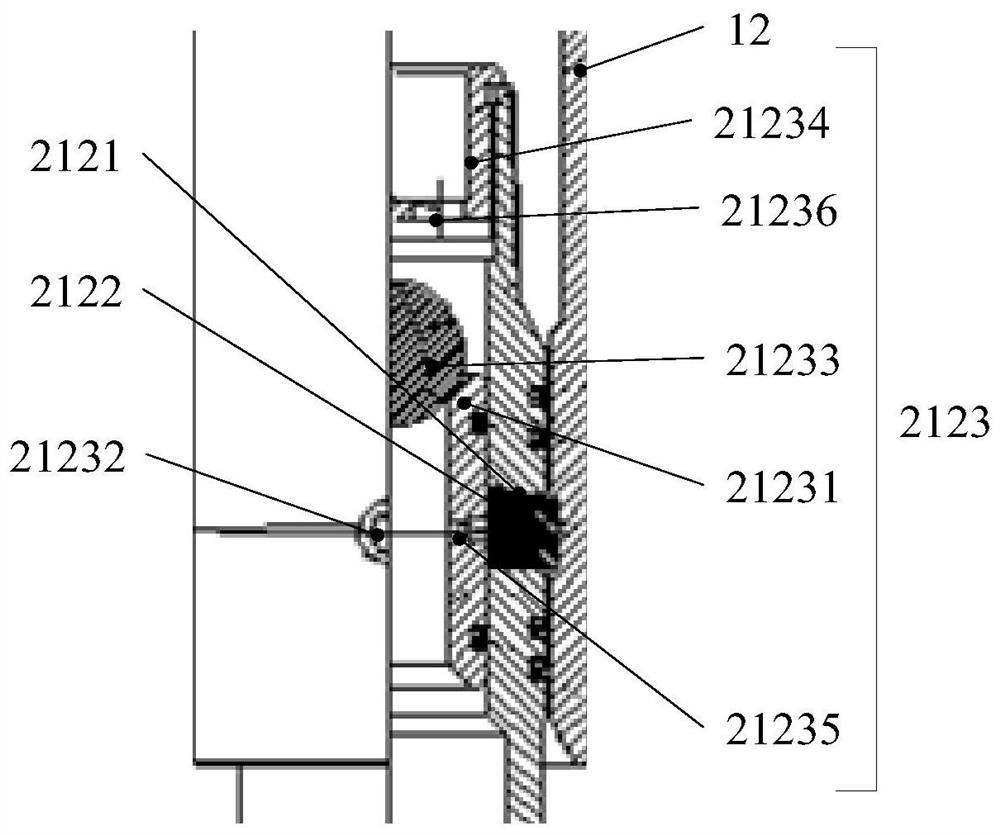

[0077] In a possible design, the scissors 21232 and the locking block 2122 are spaced apart, that is, between the scissors 21232

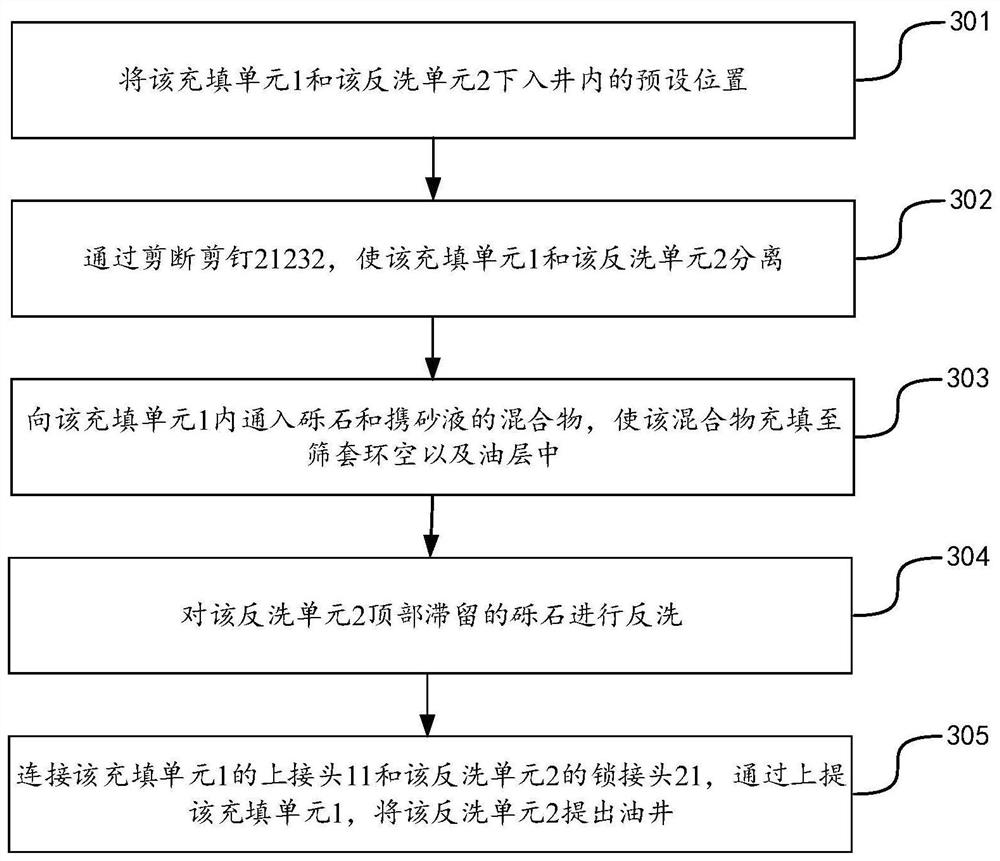

[0085] 301. The filling unit 1 and the backwashing unit 2 are lowered into a preset position in the well.

[0087] 302. By cutting off the shear nails 21232, the filling unit 1 and the backwashing unit 2 are separated.

[0091] 304, backwash the gravel retained at the top of the backwashing unit 2.

[0093] After the above steps, the device completes the gravel-packing operation, and does not remain in the well aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com