Wave energy conversion device and conversion method

A conversion device and wave energy technology, applied in hydropower, engine components, machines/engines, etc., can solve the problems of low energy conversion rate of hard and brittle, expensive materials, poor tensile strength, etc., and achieve strong environmental adaptability, High energy conversion efficiency and avoid strong impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

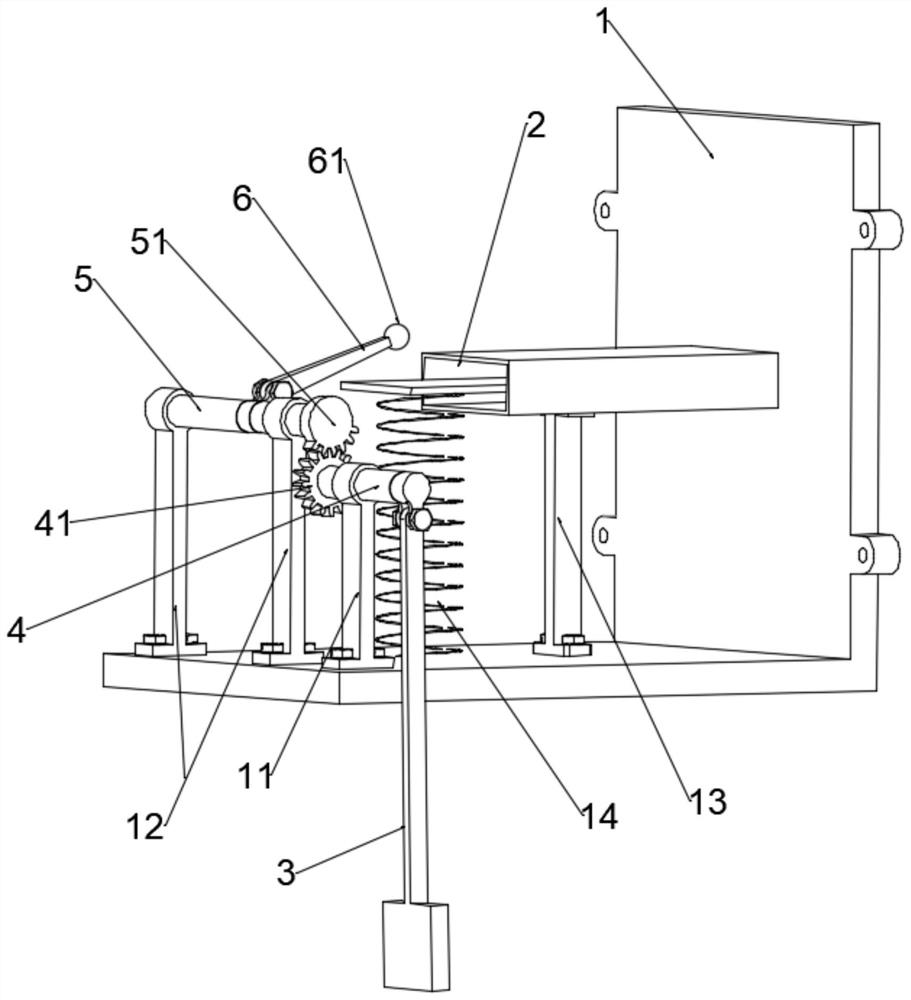

[0036] Such as Figure 1 to Figure 3 As shown, this embodiment provides a wave energy conversion device, including a transmission pendulum 3 , a fixing base 1 , and a transmission mechanism and an energy collection mechanism 2 fixedly installed on the fixing base 1 .

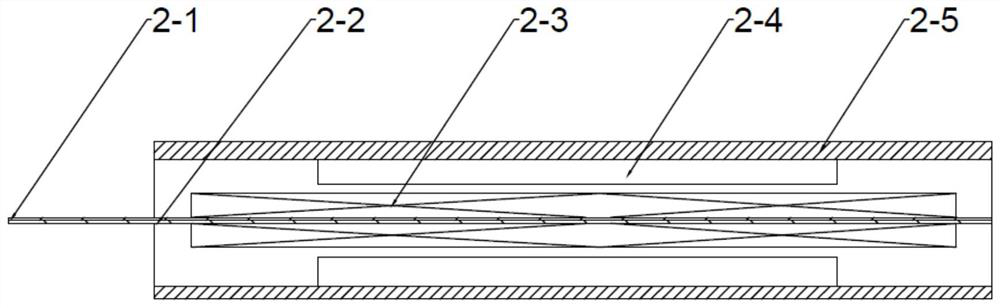

[0037] The energy harvesting mechanism 2 comprises a magnetostrictive sheet, an induction coil 2-3, a permanent magnet 2-4 and a magnetically conductive shell 2-5, wherein the magnetostrictive sheet is a Galfenol sheet 2-1, and the bottom bread of the Galfenol sheet 2-1 Covered with a beryllium bronze sheet 2-2, one end of the magnetostrictive sheet is fixed on the side wall of the fixed base 1, and the other end protrudes outside the magnetically conductive shell 2-5 to form a cantilever beam. The Galfenol sheet 2-1 and the beryllium bronze sheet 2-2 are bonded and connected by epoxy resin, so that the cantilever beam of the magnetostrictive sheet can bear a large bending range. The induction coil 2-3 is wound...

Embodiment 2

[0055] A wave energy conversion device provided in this embodiment is different from Embodiment 1 in that:

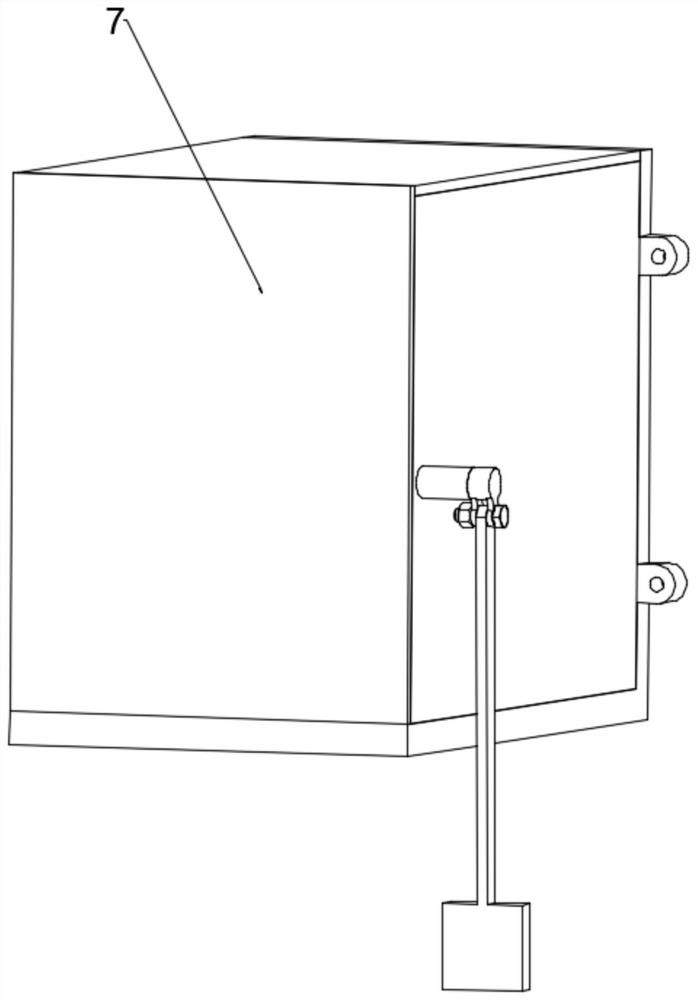

[0056] Such as Figure 4 As shown, the side wall of the fixed seat in this embodiment is fixedly connected to the support 8 . The wave energy conversion structure and the support are connected and fixed by bolts and nuts, and then placed at an appropriate water depth on the shore. This kind of energy conversion and collection is convenient for water basins without embankments, and it is easy to install and has a wide range of applications. For river basins with embankments, the wave energy conversion device is connected and fixed with the expansion bolt installed on the embankment through screw holes through nuts, and the installation height can be determined according to the actual environmental conditions of the river.

[0057] For other specific structures and implementation steps, please refer to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com