Laser-assisted mechanical rock breaking test device

A test device, laser-assisted technology, applied in the direction of measuring devices, test machinability, instruments, etc., can solve the problems of high drilling cost, long cycle, low drilling efficiency, etc., to improve safety, reliability and precision, and ensure cleanliness , to avoid the effect of premature exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and example the present invention will be further described:

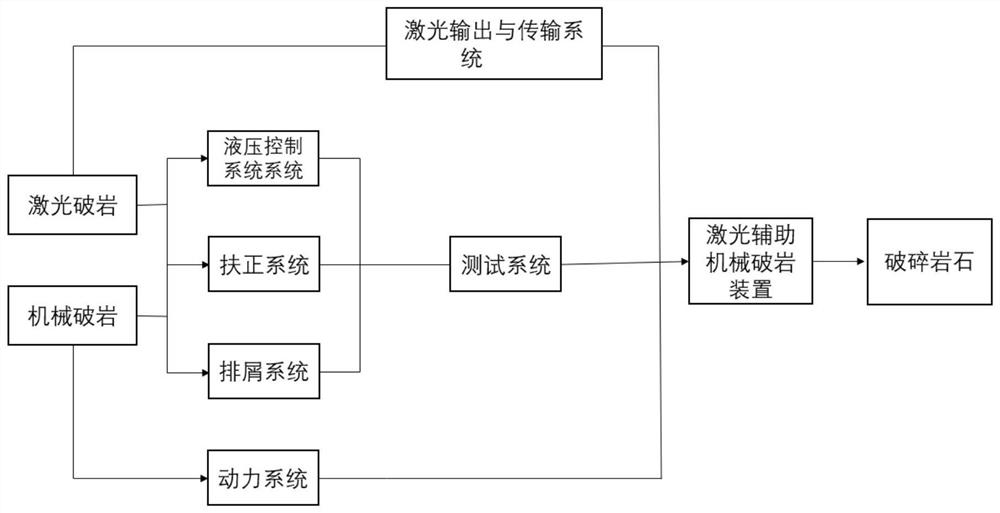

[0030] Such as figure 1 As shown, a laser-assisted mechanical rock breaking test device of the present invention is mainly composed of a power system, a laser output and transmission system, a hydraulic control system, a chip removal system, a righting system and a testing system.

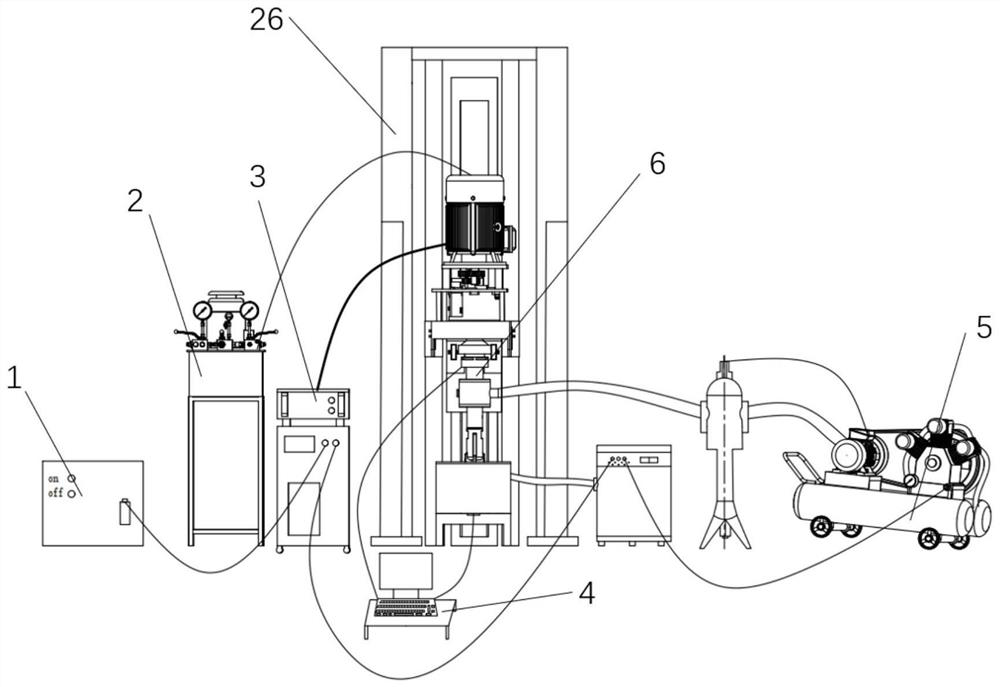

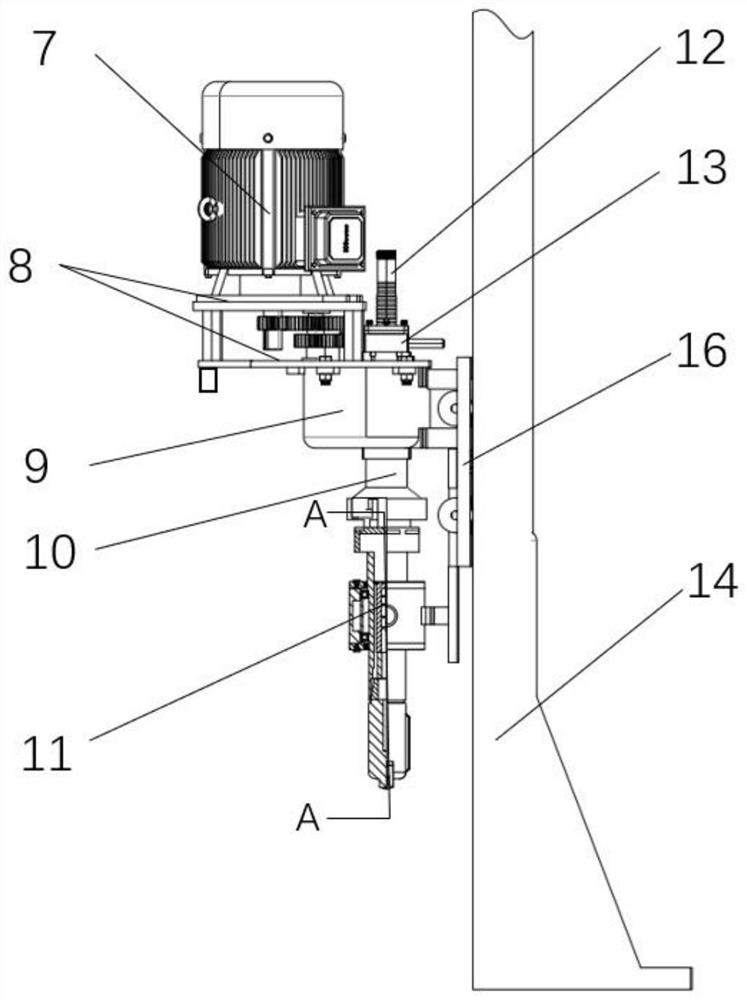

[0031] Such as figure 2 , image 3 , Figure 4 , Figure 5 As shown, the power system is composed of a variable frequency motor 7, an intermediate plate 8, a reduction box 9 and a connection plate 10. The variable frequency motor 7 and the reduction box 9 are respectively fixed on the intermediate plate 8 by four bolts, the lower two ends, and the reduction box 9 is connected to the roller support plate 16 by lug plate bolts, and the connecting disc 10 is screwed to the top of the drill pipe 20. Further, the inside of the connecting disc 10 is connected to the output shaft of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com