Pipeline hydraulic transient simulation method implicitly considering dynamic friction resistance and storage medium

A technology of hydraulic transient and simulation methods, which is applied in complex mathematical operations, instruments, electrical digital data processing, etc., and can solve problems such as inaccurate and inefficient methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

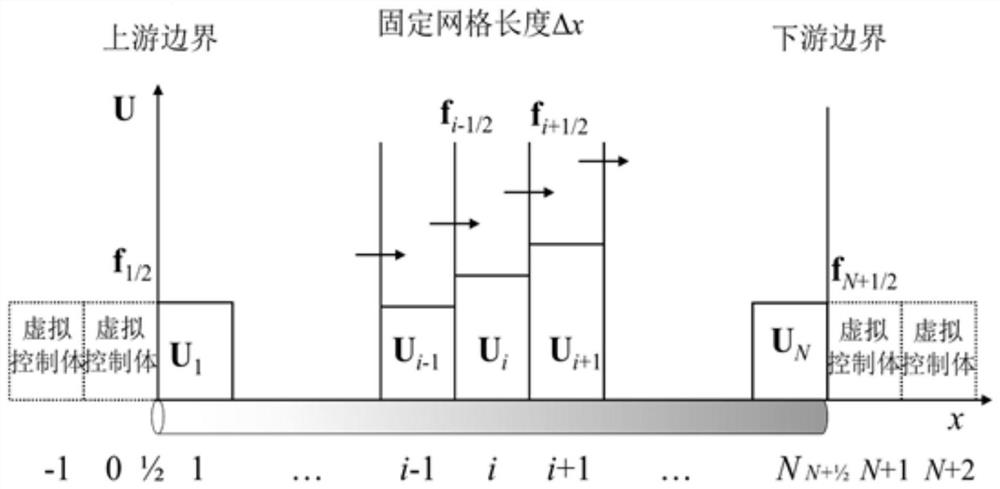

[0086] Such as figure 1 As shown, a pipeline hydraulic transient simulation method that implicitly considers dynamic friction includes the following steps:

[0087] Step 1, establishing a pipeline hydraulic transient mathematical model, the basic equation of which is the non-constant pipeline control equation considering Brunone (Bruno) dynamic friction;

[0088] The governing equation of the pipeline hydraulic transient mathematical model is:

[0089]

[0090]

[0091] In the formula, H is the water head of the piezometric tube; V is the average flow velocity in the pipeline; a is the speed of sound wave propagating in water; g is the acceleration of gravity; x is the distance along the pipeline axis; t is time; D is the pipe diameter; f q It is the quasi-steady-state friction coefficient, which is determined by Hagen-Poiseuille (Hagen-Poiseuille) law or Colebrook-White (Kolebrook-White) formula. When the Reynolds number Re is less than 2320, that is, laminar flow stat...

Embodiment 2

[0187] A computer-readable storage medium storing one or more programs comprising instructions that, when executed by a computing device, cause the computing device to perform pipeline hydraulics implicitly considering dynamic friction Transient simulation method.

[0188] A computing device comprising, one or more processors, memory, and one or more programs, wherein the one or more programs are stored in the memory and configured to be executed by the one or more processors, the The one or more programs include instructions for performing a pipeline hydraulic transient simulation method that implicitly considers dynamic friction.

Embodiment 3

[0190] The initial conditions brought into the actual working conditions, including the upstream reservoir or tank head H r , the pipe diameter D, the number N of control bodies divided according to the length of the pipe, and the length Δx of each control body, the pipe wave velocity a, the Reynolds number Re, etc., the piezometric head H of each control body in the pipeline can be obtained and flow velocity V, thus realizing the simulation of pipeline hydraulic transients.

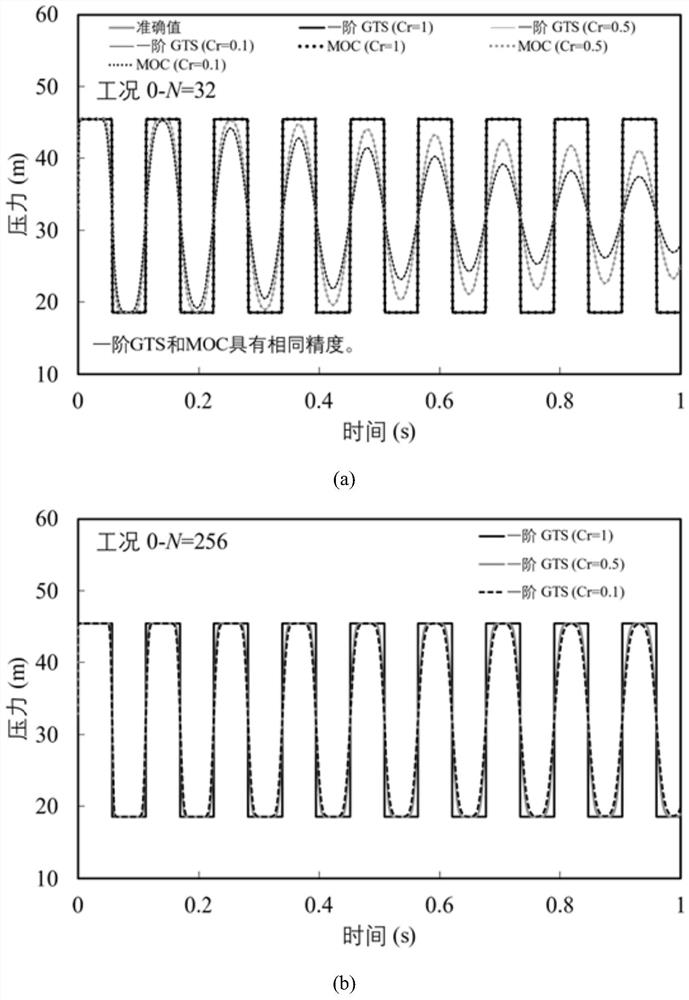

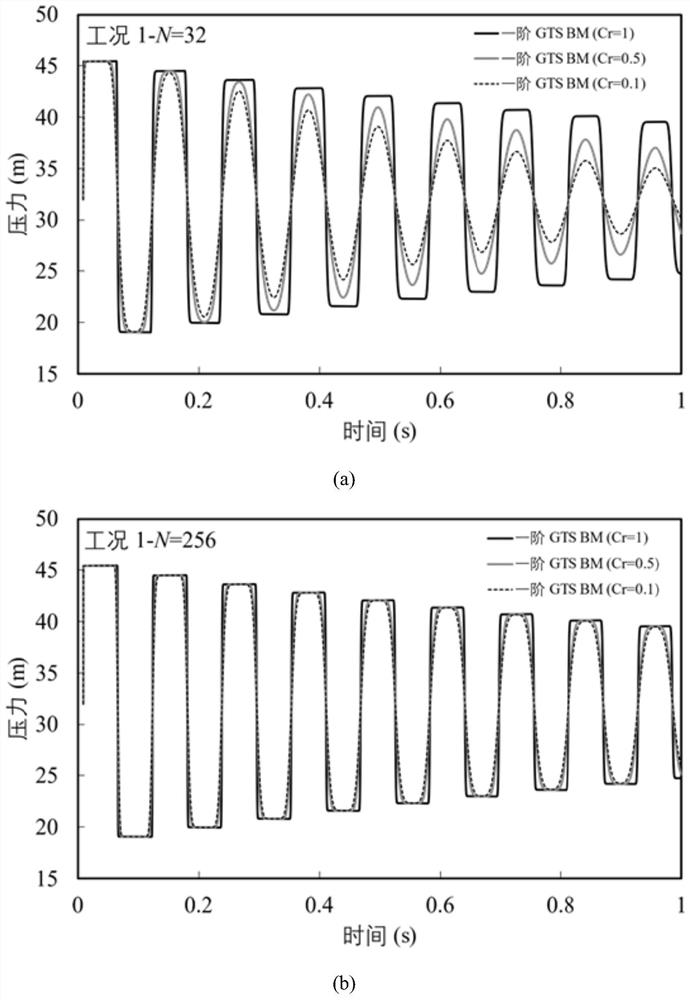

[0191] In order to verify and analyze the simulation effect of the pipeline hydraulic transient simulation method implicitly considering dynamic friction of the present invention, the pipeline hydraulic transient experimental device system designed and built by Bergant in 2001 was selected to verify the effectiveness of the method of the present invention. The condition is: the constant water head of the upstream tank is 32m, the pipe diameter is 22.1mm, and the pipe length is 37.23m. The measured wave v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com