Path optimization method for material distribution of multi-objective discrete assembly workshop

A technology for assembly workshop and route optimization, which is applied in the direction of instruments, manufacturing computing systems, data processing applications, etc., can solve problems that cannot cope with real-time status update changes, consume large computing time, constrain the application of intelligent optimization algorithms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The present invention will be further described below in conjunction with drawings and embodiments.

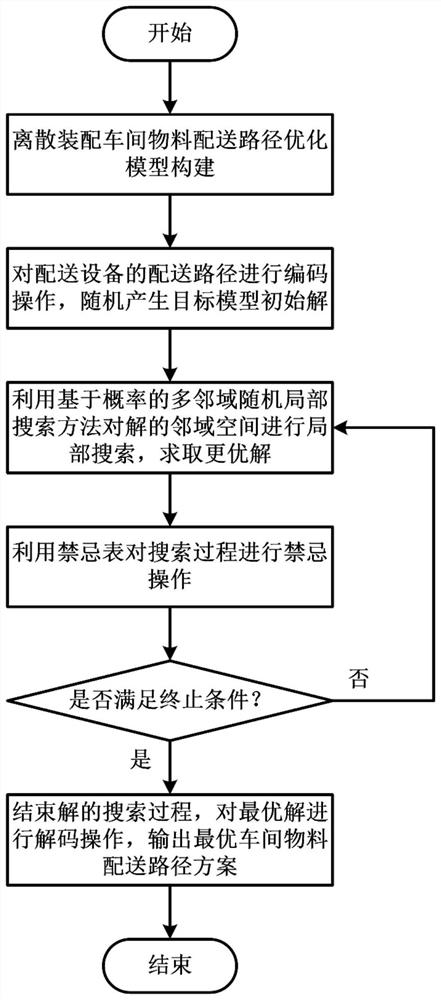

[0087] see figure 1 , a route optimization method for material distribution in a multi-objective discrete assembly workshop, including the following steps:

[0088] S1. Taking the optimization of distribution equipment transportation time consumption, distribution service satisfaction and distribution equipment load as the problem optimization objectives, the overall modeling of the material distribution path optimization process in discrete assembly workshops is carried out.

[0089] According to the scenario of material distribution in a discrete assembly workshop where multiple distribution equipment with capacity constraints deliver materials to multiple stations with different material arrival expected times, the following mathematical model is constructed:

[0090] the s ij =v×t ij (1)

[0091]

[0092] 0i ≤D max (3)

[0093]

[0094]

[0095]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com