Rice screening device for rice processing with impurity removal and dust fall functions

A rice processing and screening device technology, applied in the field of grain processing, can solve problems such as incomplete screening, achieve the effects of rapid collection and sorting, ensure the quality of rice, and improve the purity of rice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

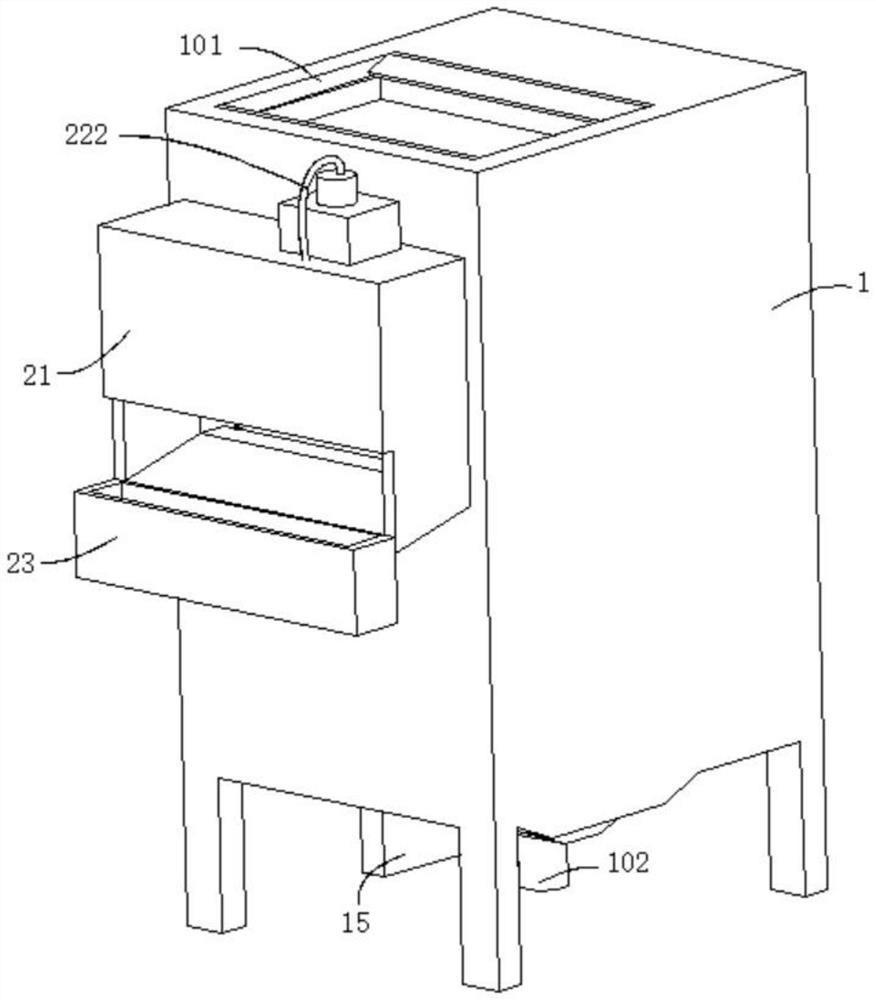

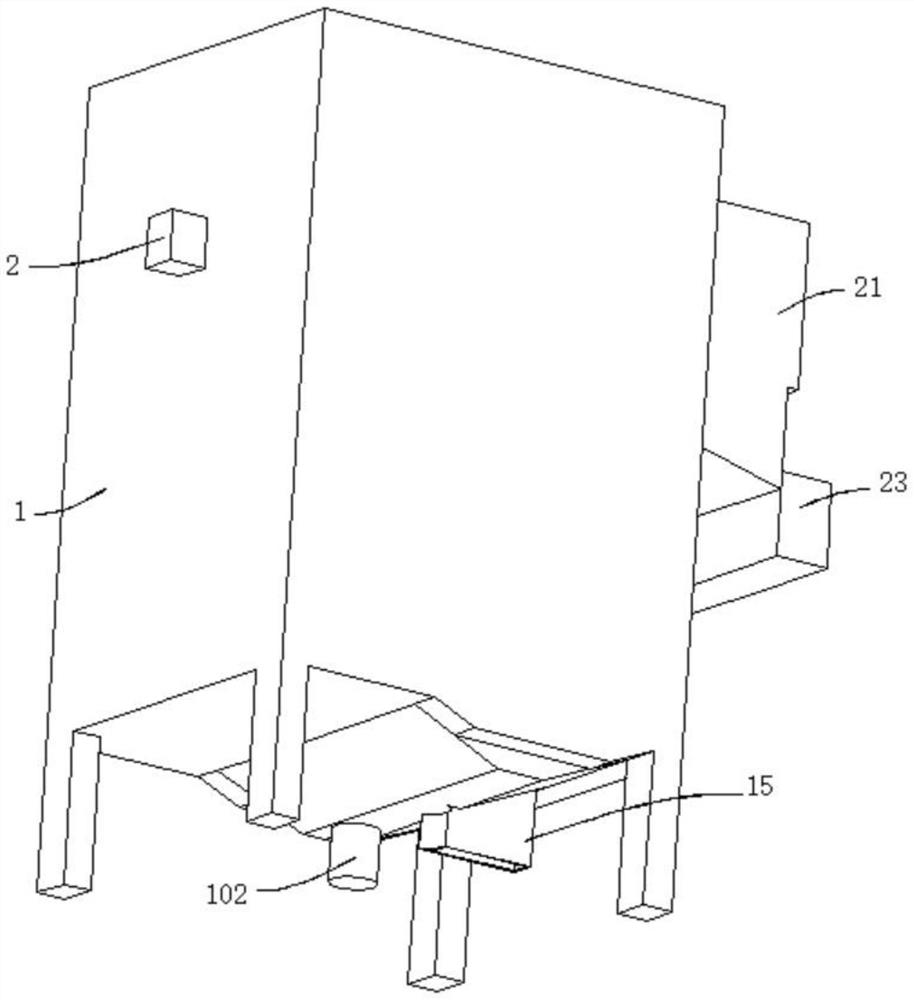

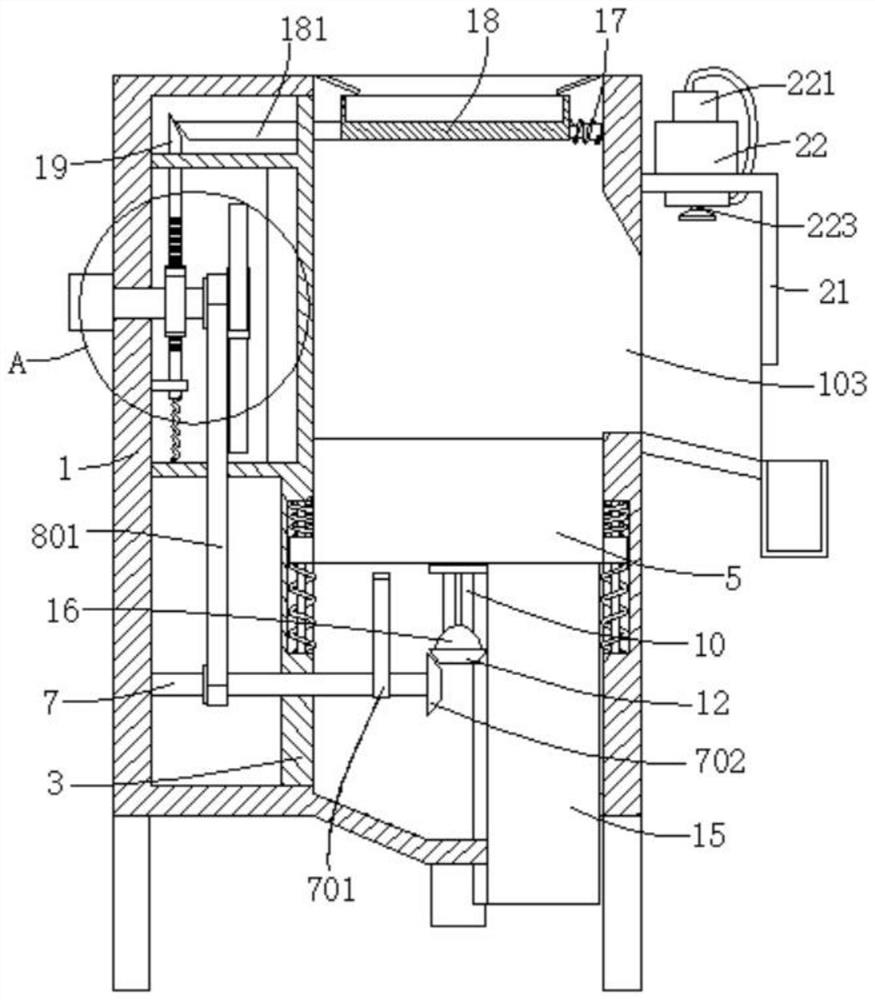

[0040] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 9 , a rice screening device for rice processing with both impurity removal and dust reduction functions, comprising a processing box 1, the top and bottom of the processing box 1 are respectively connected with a feed port 101 and a discharge port 102, and the outer wall of the processing box 1 is connected with a motor 2 , the output end of the motor 2 is connected with a rotating shaft 201, the end of the rotating shaft 201 away from the motor 2 passes through the processing box 1 and is connected with a rotating disk 202, the outer wall of the rotating disk 202 is connected with a fan blade 2021, and the inner wall of the processing box 1 is connected with a support frame 3, The outer wall of the support frame 3 is connected with a heating pipe 4, and the outer wall of the processing box 1 is dug with a dust port 103, and the outer wall of the dust port 103 is connected with a dust suppression mechanis...

Embodiment 2

[0043] refer to image 3 , Figure 4 , Figure 6 , Figure 7 , Figure 8 , Figure 10 and Figure 11 , a rice screening device for rice processing with both impurity removal and dust reduction functions is basically the same as in embodiment 1, furthermore, a casing 9 is connected to the screening grid 5 through bearing rotation, and the inner wall of the casing 9 is connected to a Rotating rod 10, the inner wall of the processing box 1 is connected with a support plate 16, the rotating rod 10 is connected in the supporting plate 16 in rotation, the outer wall of the rotating rod 10 is connected with a guide bar 11, and the inner wall of the casing 9 is dug with a guide groove matching the guide bar 11 901, the bottom of the rotating rod 10 is connected with the second bevel gear 12, the outer wall of the rotating shaft 7 is connected with the first bevel gear 702 meshed with the second bevel gear 12, and the inner wall of the screening grid 5 is dug with a groove 501, th...

Embodiment 3

[0046] refer to Figure 1-5 , a rice screening device for rice processing with both impurity removal and dust reduction functions is basically the same as in Example 1, furthermore, the inner wall of the feed inlet 101 is connected with a spring telescopic rod 17, and the outer wall of the spring telescopic rod 17 is connected with a filter screen Frame 18, the outer wall of screen frame 18 is connected with force bar 181, and force bar 181 is slidingly connected in support frame 3, and rotating shaft 201 outer wall is connected with semi-gear 203, and half-gear 203 outer wall meshing is connected with rack plate 19, rack The plate 19 is slidably connected in the support frame 3, the rack plate 19 is movable against the force bar 181, the bottom of the rack plate 19 is connected with a third elastic element 191, the third elastic element 191 is connected to the outer wall of the support frame 3, and the processing box 1. The inner wall is connected to the limiting frame 20, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com