Municipal sewer grating plate carrying device with positioning function

A technology of handling device and positioning device, which is applied in the direction of transportation and packaging, multi-axis trolley, trolley accessories, etc., can solve the problems of manual handling for installation, achieve good practical value, expand the scope of use, and avoid left and right shaking and collision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

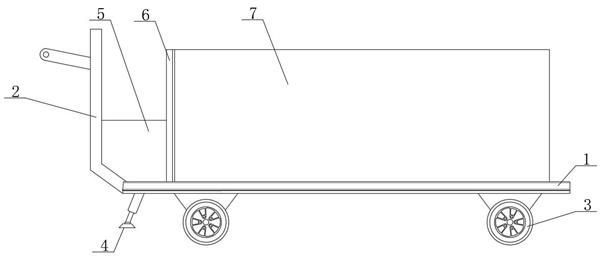

[0026] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , the present invention provides a technical solution:

[0027] A municipal sewer grill plate handling device with positioning function,

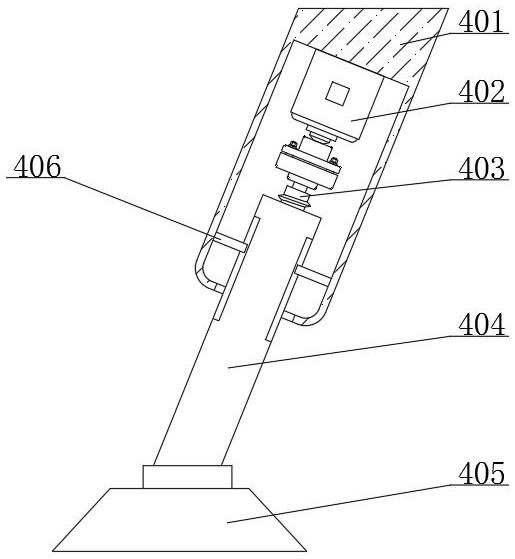

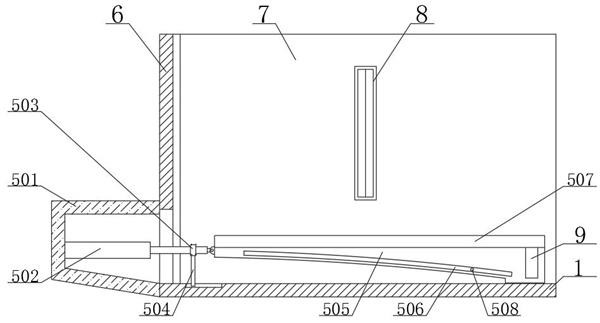

[0028] Workflow: When using the power supply, some administrative units often need to replace the sewer grille. At this time, by moving the device, the base 1 is driven by the hand-held push plate 2, and then moved to the position of the sewer. At this time, by starting The rotating motor 402 drives the supporting threaded rod 403 to rotate, and the supporting threaded rod 403 drives the supporting threaded sleeve 404 to move, and the set limit rod 406 ensures that the supporting threaded sleeve 404 moves stably. That is, at this time, the sliding plate 505 is driven to move by starting the electric telescopic rod 502. When it moves to the right side, under the action of the fixed column 508, the sliding plate 505 is moved to the right, and the sliding pl...

Embodiment 2

[0030] In Embodiment 2, the same parts as Embodiment 1 will not be described in detail. The difference is that after the installation is completed, when the sewer grille needs to be replaced, the sliding plate 505 is moved by starting the electric telescopic rod 502 to make it Located on the right side, then by placing the sewer grid plate above the support slideway 507, then the blocking device 9 plays the purpose of blocking, at this time, it is reset by starting the electric telescopic rod 502, and then it drives the support slideway 507 moves, and then drives the sewer grating to move, and when it moves to the outside of the guide frame 801 on the outside of the central baffle plate 7, it is set in an arc shape because the outside of the guide frame 801, and the sewer grating is in contact with it, thereby moving it to the two sides. Side extrusion, under the action of the telescopic rod 802 and the telescopic spring 803, makes its guide frame 801 move to both sides, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com