Multi-specification security door robot unstacking and stacking clamp

A technology of anti-theft doors and robots, which is applied in the direction of object unstacking, object stacking, transportation and packaging, etc. It can solve problems such as high labor intensity, difficulty in recruiting workers, and poor working environment to ensure safety and reliability. , increase the manufacturing cost and risk factor, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

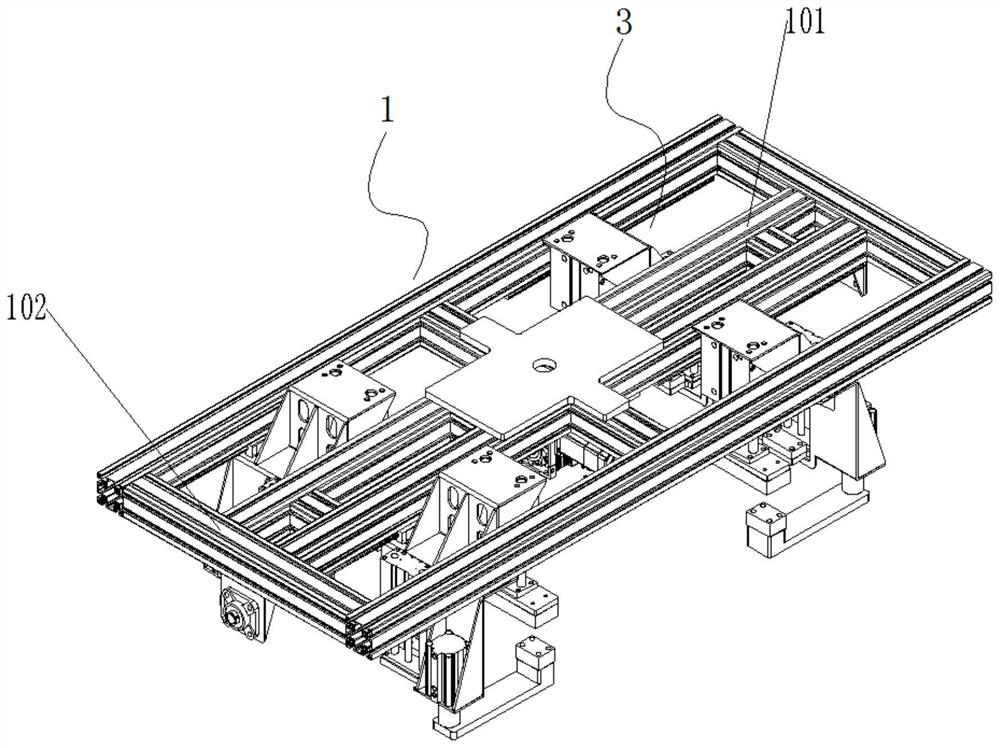

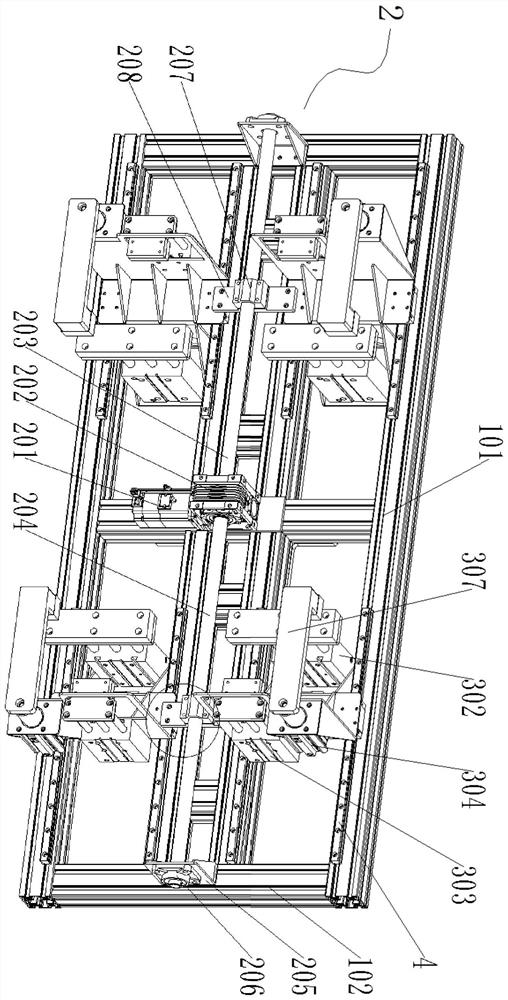

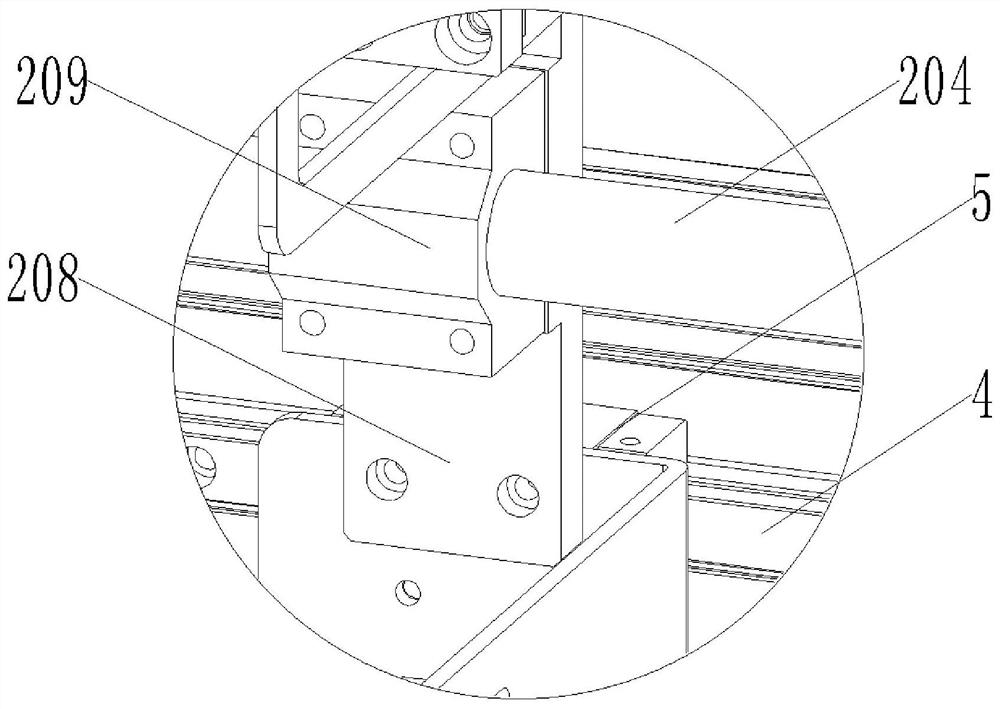

[0022] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-Figure 7 As shown, the robot depalletizing and stacking fixture for multi-standard anti-theft doors can realize the grabbing of anti-theft doors. It mainly includes a support frame 1, a driving device 2, and a rotating clamping device 3. A robot movement shaft is arranged on the support frame. The support frame and the structure on it can be rotated by 90 degrees, so that the horizontal placement of the anti-theft door becomes vertical placement. The support frame 1 looks like a Chinese character from the top view. In order to facilitate description and understanding, the support frame 1 corresponds to Tianzi, and the direction is used as a distinguishing point. In the robot unstacking and palletizing fixture, the frame part that is parallel to the left-handed screw 203 and the right-handed screw 204 is called the horizontal side column 101 (that is, the Tianzi h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com