Anti-blue-spraying agent for shoe material and preparation method thereof

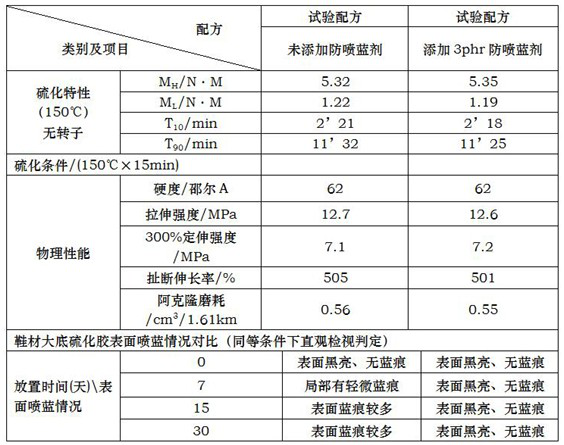

A technology of anti-blowout and blue agent, applied in shoe soles, footwear, applications, etc., can solve the problem of insufficient combustion of low molecular aromatic hydrocarbons, and achieve the effects of large specific surface area, reduced manufacturing cost, and rich pore structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention are clearly and completely described below.

[0029] The invention discloses an anti-blowout agent for shoe materials. The raw materials include 55-80 parts of modified multi-wall carbon nanotubes, 20-45 parts of organic adsorbent and 2-6 parts of silane coupling agent in parts by weight.

[0030] Preferably, in parts by weight, the raw materials include: 67 parts of modified multi-walled carbon nanotubes, 28 parts of organic adsorbent, and 5 parts of silane coupling agent.

[0031] Preferably, the modified multi-walled carbon nanotubes are hydroxylated carbon nanotubes.

[0032] Preferably, the organic adsorbent is carboxymethyl cellulose.

[0033] Preferably, the silane coupling agent is bis-[γ-(triethoxysilyl)propyl]tetrasulfide.

[0034] A kind of preparation method of anti-blooming agent for shoe material, comprises the following steps:

[0035] Step (1): putting the modified multi-walled carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com