Efficient dust removal equipment

A kind of dust removal equipment and high-efficiency technology, which is applied in the direction of gas dust removal, dispersed particle separation, chemical instruments and methods, etc., can solve cumbersome problems that affect the dust removal efficiency of equipment, improve safety, realize unmanned factories, and improve dust removal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

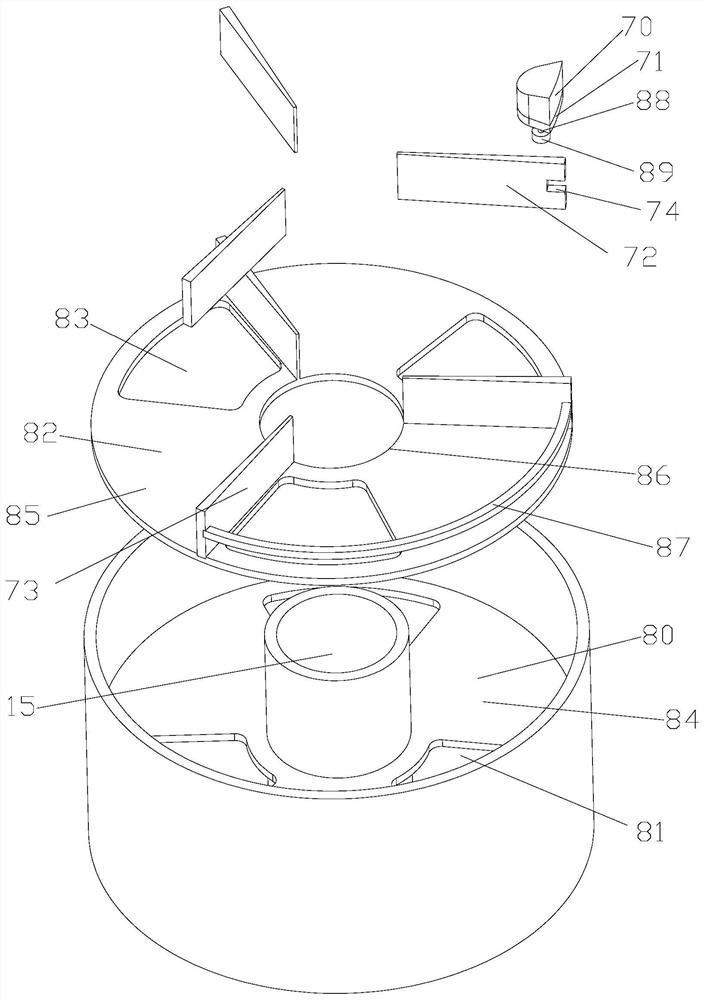

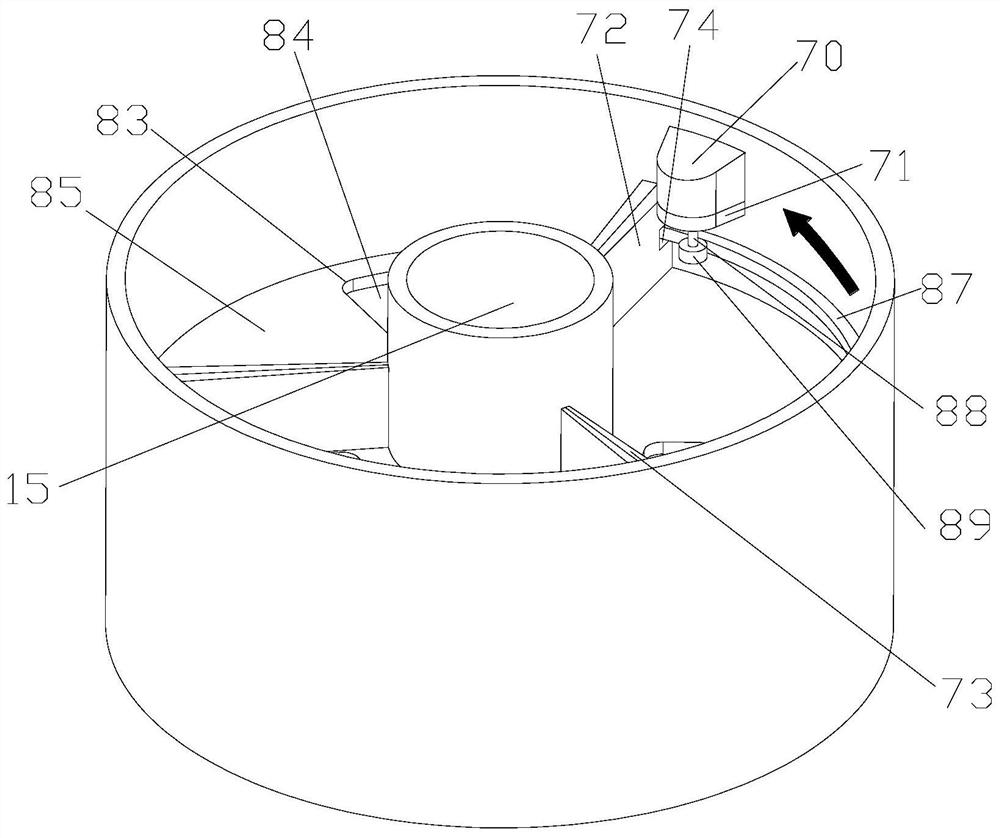

[0034] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that the embodiments are only a detailed elaboration of the present invention, and should not be regarded as limiting the present invention. All the features disclosed in the embodiments of the present invention, or disclosed All method or process steps can be combined in any way, except for mutually exclusive features and / or steps.

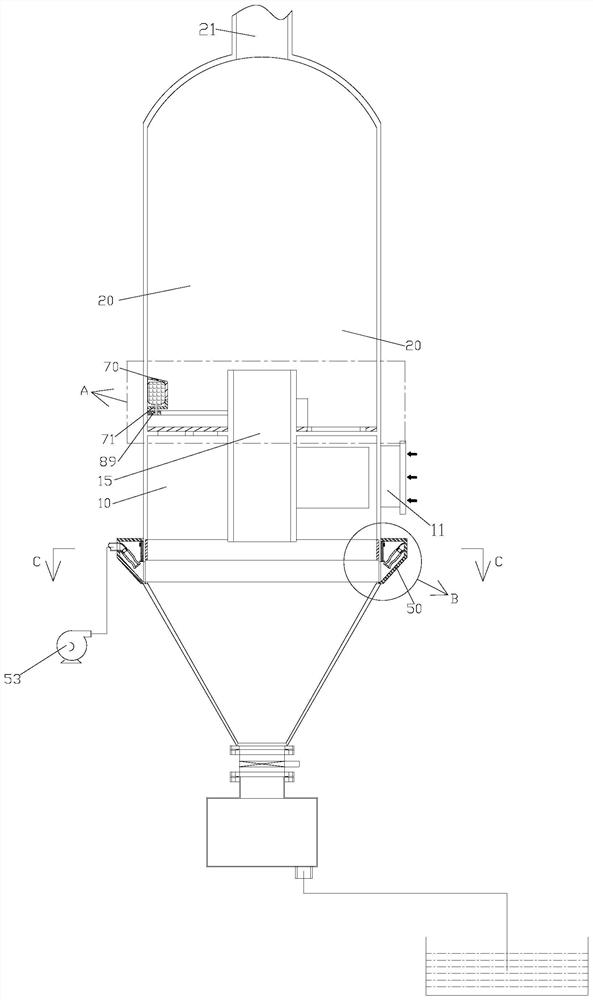

[0035] This embodiment provides a high-efficiency dust removal equipment, including at least two stages of dust removal devices, these dust removal devices are used to reduce dust in high-temperature pyrolysis gas, after they work for a long time, a large amount of sludge will be generated inside the dust removal devices at all levels, these sludges are generally It is in the form of powder or block. If the sludge in the dust removal devices at all levels is not discharged in time, it will affe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap