Auxiliary runway repairing device

A runway and eleventh technology, applied in the field of runway auxiliary repair devices, can solve the problems of high resource consumption, low efficiency, and heavy workload of workers, and achieve the effect of high work efficiency and easy repair work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

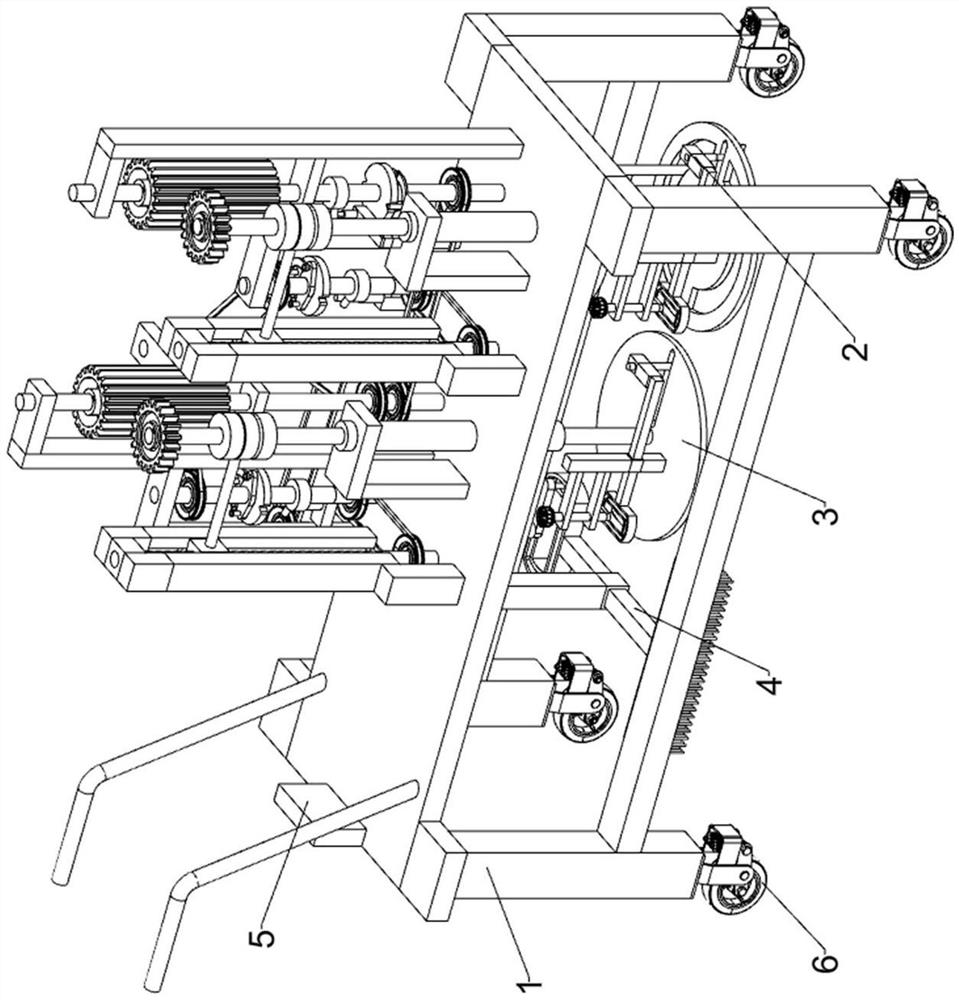

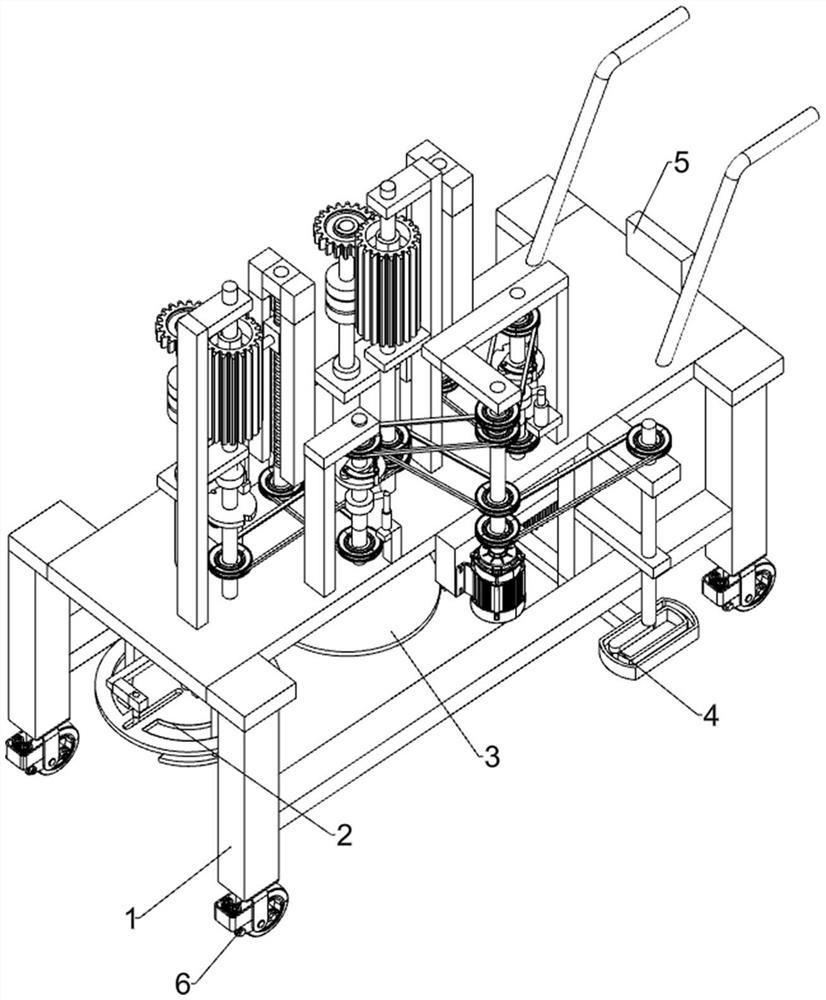

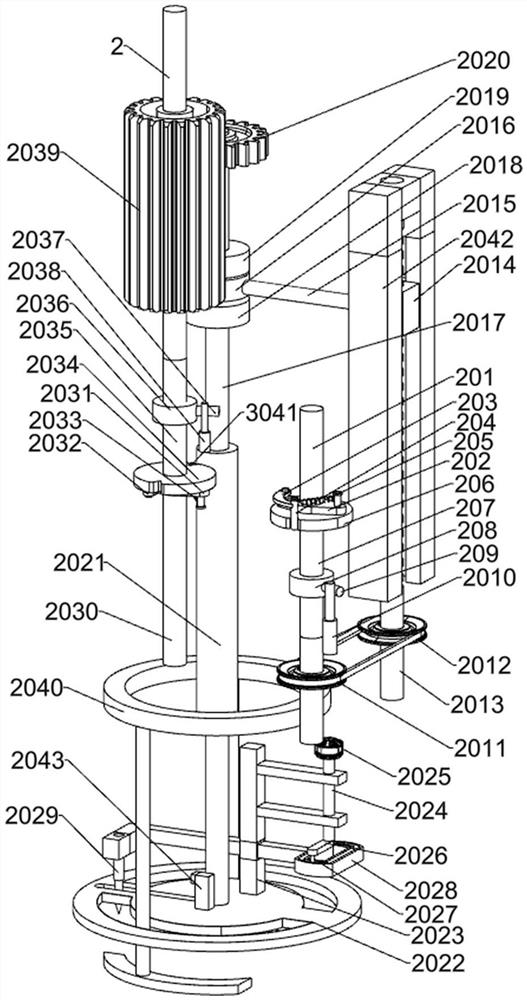

[0030] A runway aid repair device such as Figure 1-9 As shown, it includes an underframe 1, a cutting mechanism 2, a chamfering mechanism 3, a cleaning mechanism 4, a control panel 5 and a wheel 6; a control panel 5 is arranged above the underframe 1; The mechanism 3 is connected with the cleaning mechanism 4; the bottom of the chassis 1 is connected with the wheel 6; the cutting mechanism 2 is connected with the chamfering mechanism 3; the cutting mechanism 2 is connected with the cleaning mechanism 4; the chamfering mechanism 3 is connected with the cleaning mechanism 4 connect.

[0031] When preparing for work, push the chassis 1 so that the wheel 6 drives the device to move to the front of the hole in the plastic runway, and then continue to push the device so that the cutting mechanism 2 is located above the hole in the plastic runway. At this time, the control panel 5 controls the movement of the cutting mechanism 2, so that The cutting mechanism 2 is adjusted accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com