Diesel engine and flame glow plug thereof

A diesel engine and glow plug technology, applied in engine components, engine starting, machine/engine, etc., can solve the problems of short heating time, slow heating of heating elements, insufficient temperature, etc., to increase heating time and smooth cold start , the effect of promoting gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

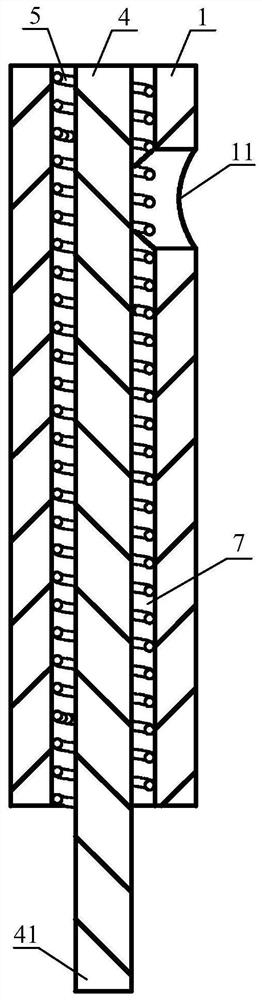

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0030] In the present invention, extremely cold conditions refer to occasions where the ambient air temperature is equal to or lower than -32°C.

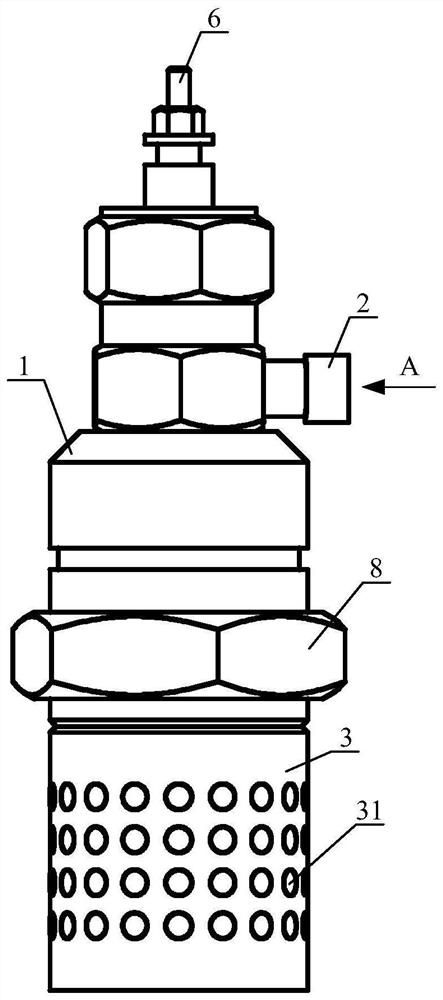

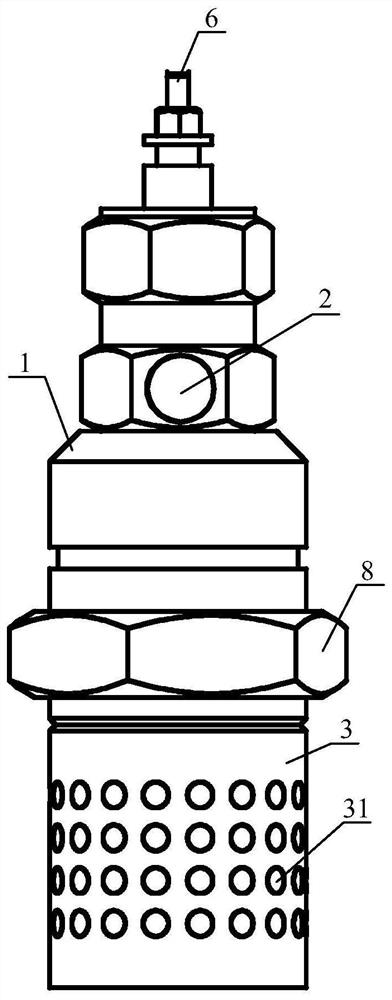

[0031] The invention provides a flame glow plug for a diesel engine, such as figure 1 with figure 2 As shown in the structure, the flame glow plug includes a housing 1, an oil inlet nozzle 2, a flame cover 3, an electromagnetic induction heating element 4, an electromagnetic induction coil 5 and an electrode 6;

[0032] The top of the housing 1 is provided with an electrode 6 for connecting to a power supply, and the bottom is provided with a cavity with an opening; the housing 1 is the basic component of the entire flame glow plug, and the top of the housing 1 is closed and the bottom is open;

[0033] The oil inlet nozzle 2 is fixedly installed on the outside of the housing 1 and communicates with the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com