Steel-aluminum composite contact rail abrasion measuring device based on ultrasonic measurement and measuring method thereof

A steel-aluminum composite and measuring device technology, applied in measuring devices, railway vehicle shape measuring devices, using ultrasonic/sonic/infrasonic waves, etc., can solve problems such as low efficiency and inaccurate measurement, and achieve high degree of automatic measurement and real-time processing Good performance, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

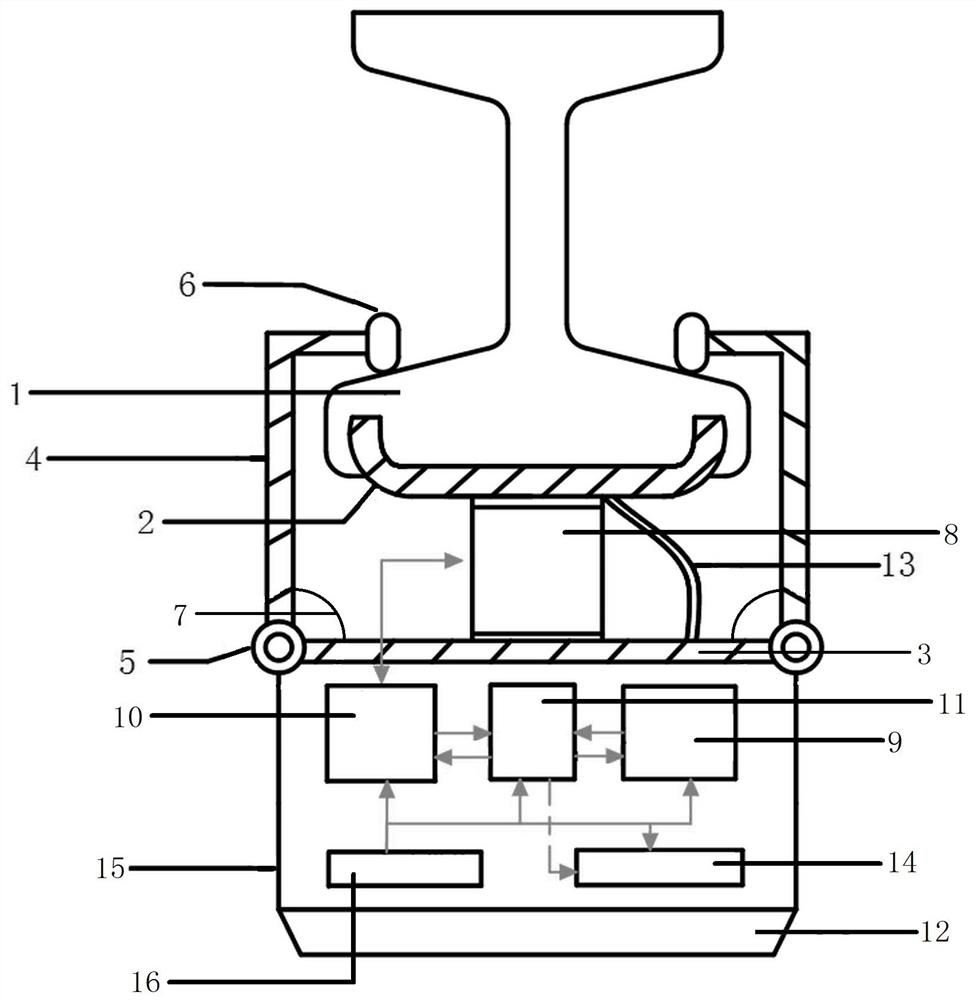

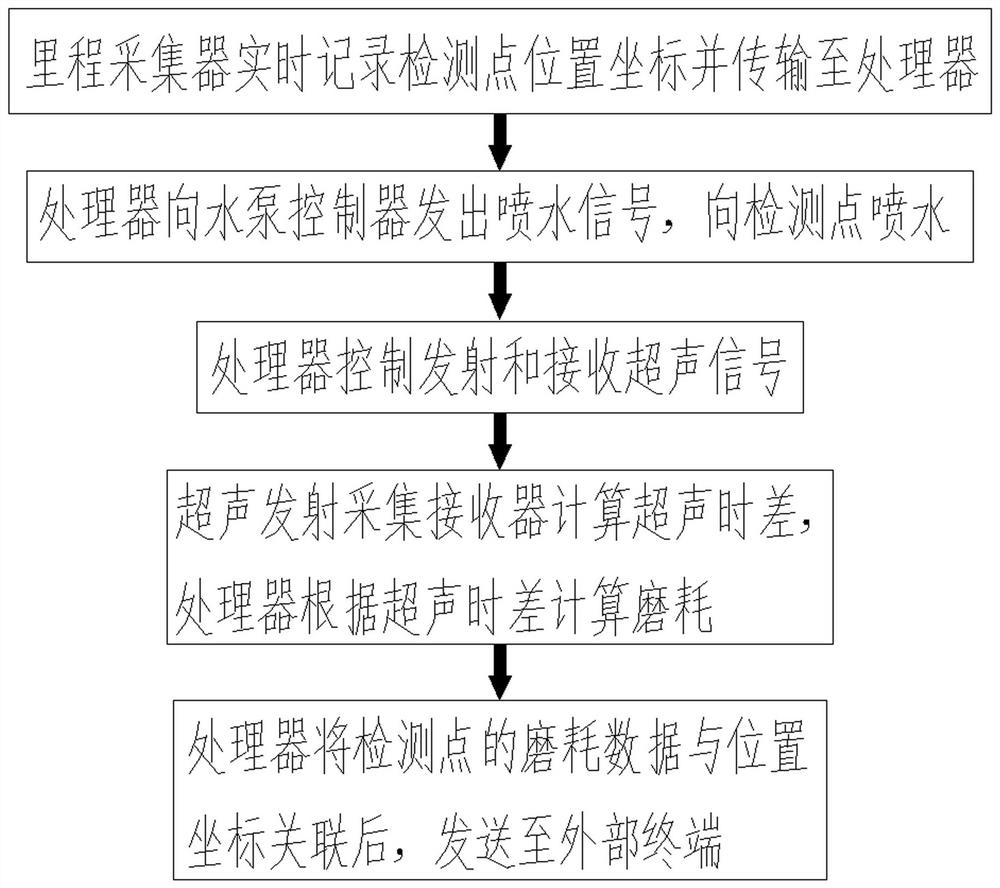

[0038] As the basic embodiment of the present invention, the present invention includes a steel-aluminum composite contact rail wear measurement device based on ultrasonic measurement, including a measuring device body and a data acquisition and processing device, wherein the steel-aluminum composite contact rail includes an aluminum seat 1 and a stainless steel belt 2 . The measuring device body includes a bottom plate 3 and two booms 4, one end of the two booms 4 is movably connected with the left and right sides of the bottom plate 3 through a rotating shaft 5, and the other end is connected with a pulley 6 slidingly connected with the aluminum base 1. A torsion spring 7 is also connected between the boom 4 and the bottom plate 3 , and the measuring device body is suspended under the steel-aluminum composite contact rail by the rotational force of the torsion spring 7 . The data acquisition and processing device is located on the upper surface of the bottom plate 3 and in th...

Embodiment 2

[0040] As a preferred embodiment of the present invention, the present invention includes a steel-aluminum composite contact rail wear measurement device based on ultrasonic measurement, including a measurement device body and a data acquisition and processing device located in the measurement device body. The steel-aluminum composite contact rail includes an aluminum seat 1 and a stainless steel strip 2 . The measuring device body includes a bottom plate 3 and four booms 4, one end of the two booms 4 on the left and right sides is respectively connected to the left and right sides of the bottom plate 3 through the rotating shaft 5, and the other end is connected to the aluminum base 1 for sliding connection. The pulley 6; the other two booms 4 can be fixedly connected to the base plate 3, or can be flexibly connected to the base plate 3 through the rotating shaft 5. A torsion spring 7 is also connected between the boom 4 and the bottom plate 3 , and the measuring device body ...

Embodiment 3

[0044] As another preferred embodiment of the present invention, the present invention includes a steel-aluminum composite contact rail wear measurement device based on ultrasonic measurement, including a measurement device body, a data acquisition and processing device and a control box 15 . The steel-aluminum composite contact rail includes an aluminum seat 1 and a stainless steel strip 2 . The measuring device body includes a bottom plate 3 and two booms 4, the two booms 4 are located on the left and right sides of the bottom plate 3 respectively, one end of the two booms 4 is movably connected with the left and right sides of the bottom plate 3 through a rotating shaft 5, and the other end All are connected with the pulley 6 that is slidingly connected with the aluminum seat 1. A torsion spring 7 is also connected between the boom 4 and the bottom plate 3. When in use, the two booms 4 are opened to open the measuring device, and then relying on the rotational force of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com