Calibration device for underwater three-dimensional observation system and calibration method

A system calibration and stereoscopic observation technology, applied in the fields of genetic law, details involving 3D image data, image data processing, etc., can solve problems such as large errors, achieve high precision, meet the requirements of calibration, and wide measurement range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

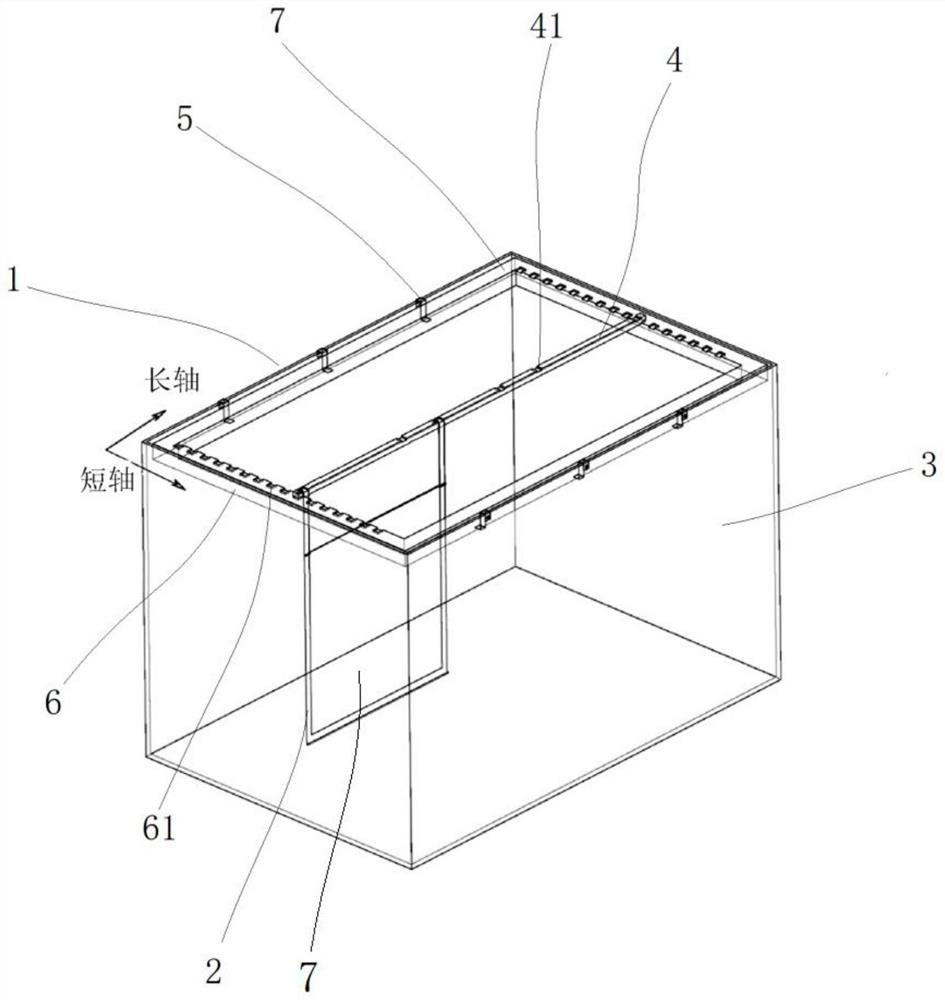

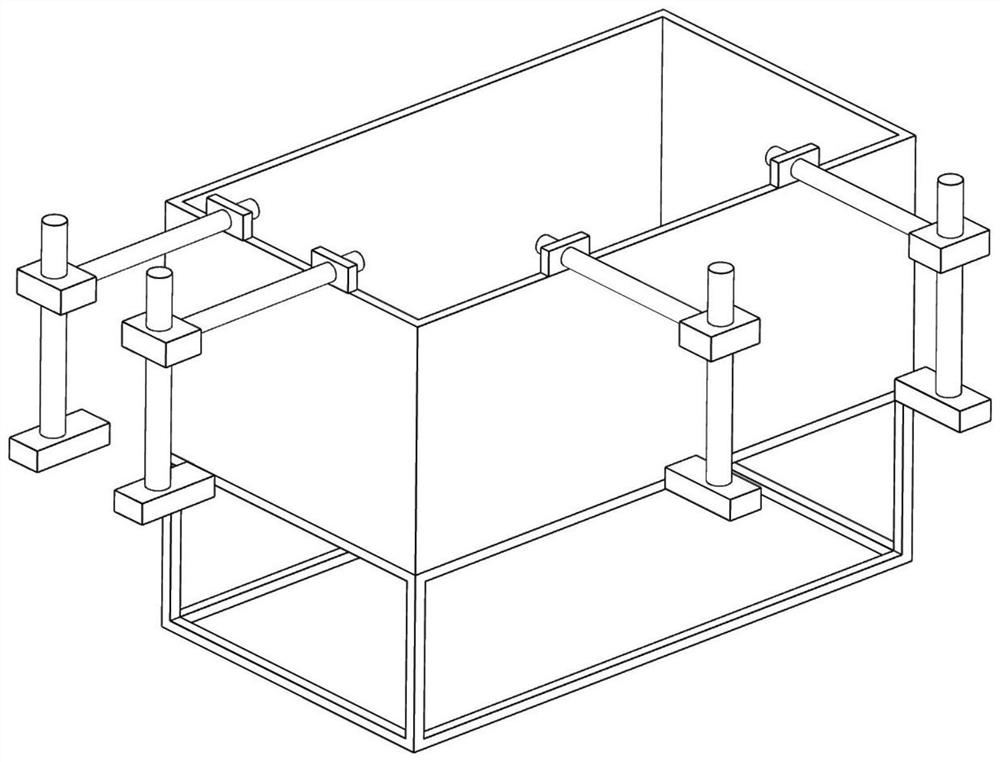

[0035] The inner diameter of the positioning track (1) is 1300×900mm, the upper and lower thicknesses are 20mm, and the width on one side is 50mm. 3) The inner wall spacing is 16mm. The hook (5) is used to connect with the glass water tank (3), and the upper plane of the positioning track (1) is flush with the top of the glass water tank (3).

[0036] The moving rod (4) has a length of 1320mm, a thickness of 20mm up and down, and a width of 20mm, and is fixed on the minor axis of the track (6) by the first draw-in groove (61).

[0037] Track minor axis (6) processes a first draw-in groove (61) (length 10mm, width 20mm, depth 10mm) every 50mm from starting position, processes 17 pairs of draw-in grooves altogether.

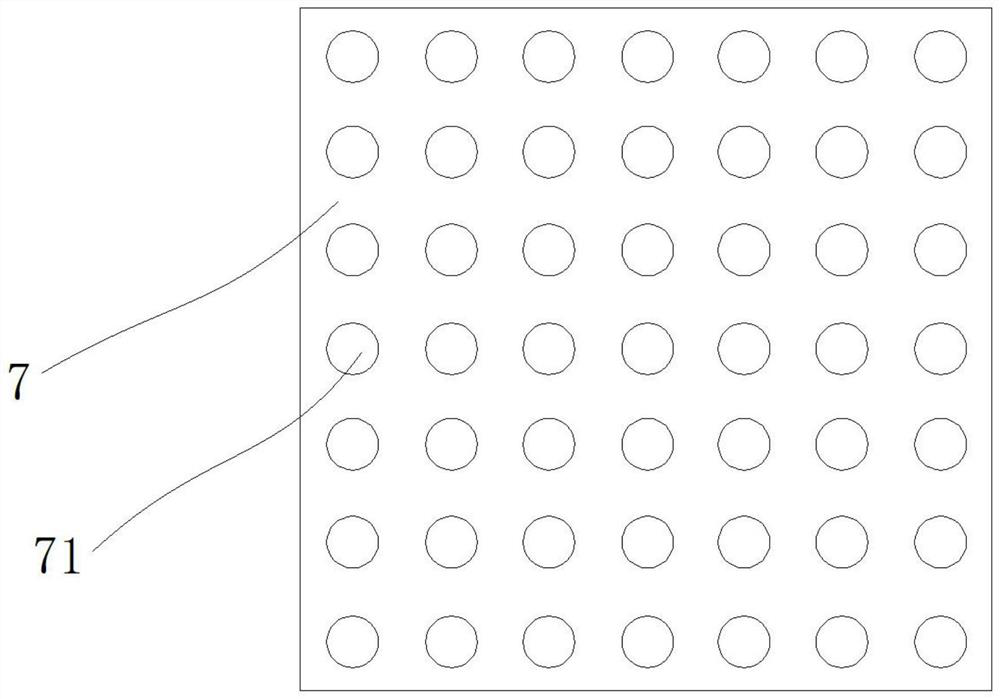

[0038] Along the direction of the long axis (7) of the track, process a pair of second slots (41) (length 20mm, width 20mm, depth 10mm) every 400mm from the starting position of the long axis on the moving rod (4), each pair of second Draw-in groove (41) is space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com