Aluminum foil processing device for manufacturing high-specific-volume ultra-small aluminum electrolytic capacitor

A technology for aluminum electrolytic capacitors and processing devices, which is applied in capacitor manufacturing, electrolytic capacitors, capacitors, etc., can solve the problem of not being able to locate aluminum foil on the aluminum foil placement seat, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

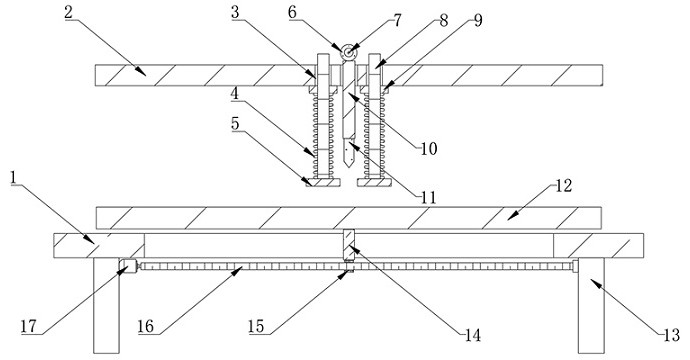

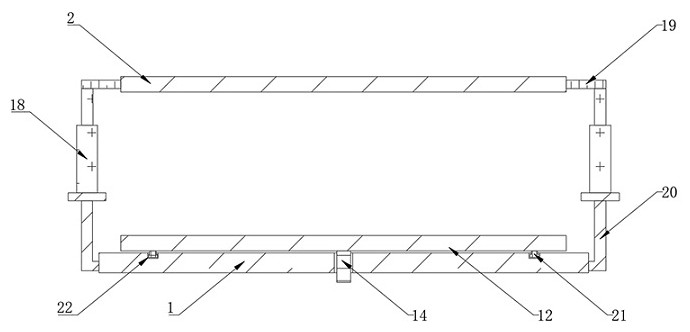

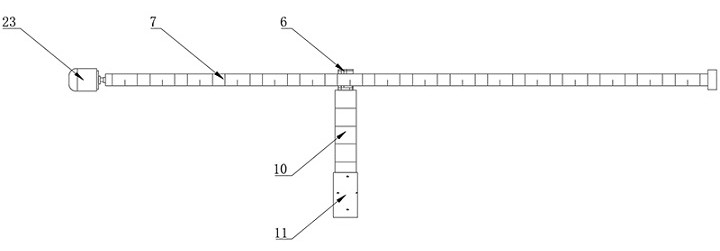

[0023] see Figure 1~4 , in an embodiment of the present invention, an aluminum foil processing device for manufacturing ultra-small aluminum electrolytic capacitors with high specific volume includes a workbench 1, an aluminum sheet placement seat 12 is connected to the top of the workbench 1, and the four corners of the bottom end of the workbench 1 are connected to There are supporting feet 13, and two mounting seats 20 are arranged on the front and rear sides of the workbench 1, and the top of the mounting seats 20 is equipped with an electric cylinder 18, and the top of the electric cylinder 18 is connected with a second connecting rod 19, four second connecting rods One side of 19 is jointly connected with support frame 2, and the top of support frame 2 is provided with four first through holes 3, and the top of support frame 2 is provided with connecting plate 10, and the top of support frame 2 is provided with four movable rods 8, The bottom of the support frame 2 is c...

Embodiment 2

[0029] refer to Figure 1~2 , an aluminum foil processing device for manufacturing ultra-small aluminum electrolytic capacitors with high specific volume. Compared with Embodiment 1, this embodiment also includes a first motor 17 installed on one side of the supporting foot 13 on the left side of the workbench 1. One side of the supporting foot 13 on the right side of the workbench 1 is provided with a second ball screw 16, the outside of the second ball screw 16 is sleeved with a second ball nut 15, and the outside of the second ball nut 15 is connected with a first connection Bar 14, the top of workbench 1 is provided with two slide grooves 22, and the bottom end of aluminum sheet placement seat 12 is equipped with two slide blocks 21.

[0030] Wherein, the joint of the second ball screw 16 and the supporting foot 13 is provided with a second roller, one end of the second ball screw 16 is connected with the second roller, and the other end of the second ball screw 16 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com