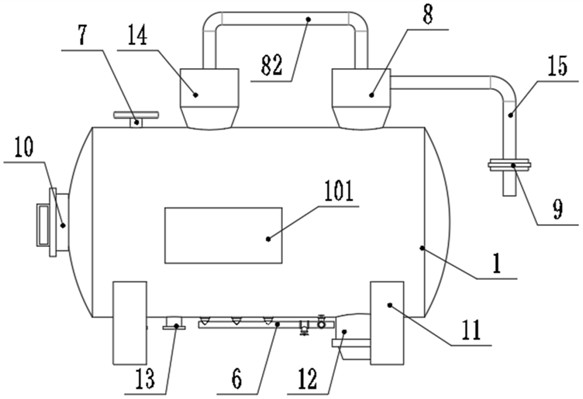

Oil-gas-water-sand four-phase separator

A phase separator, oil-gas-water technology, applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve problems such as nozzle blockage, affecting separation effect, time-consuming and labor-intensive, etc., and achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

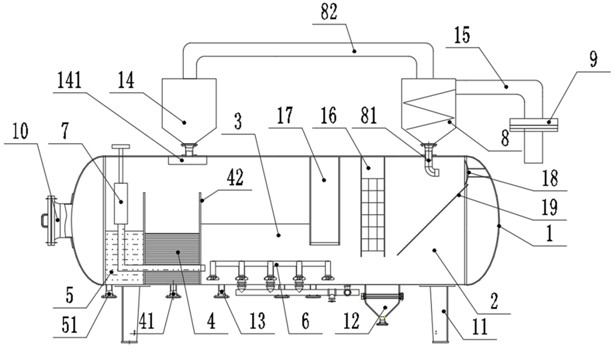

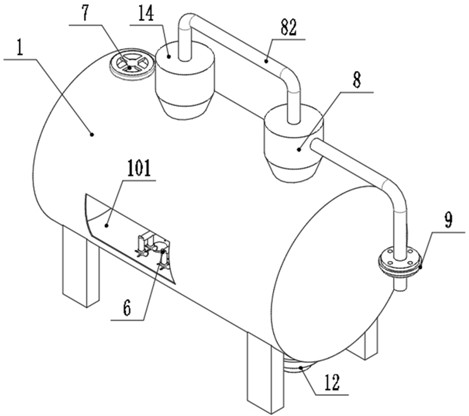

[0033] In order to enable those skilled in the art to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

[0034]The present invention is an oil, gas, water and sand four-phase separator, comprising a tank body 1 supported by outriggers 11, the tank body 1 is made of killed steel, and after non-destructive testing, the outer wall of the tank body 1 is coated with thermal insulation coating Floor. The tank body 1 is a cylinder structure with two ends as arc surfaces, and one end is provided with a manhole 10, which is convenient for manual internal maintenance and cleaning. The top of the front end of the tank body 1 is connected with a swirl tube 8, the inner wall of the swirl tube 8 is connected with a spiral plate, and the spiral plate forms a spiral channel, and the swirl tube 8 is connected with a liquid inlet pipe 15, which enters the swirl tube through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com