Horizontal oil pressure forging and pressing machine

A forging press and oil pressure technology, applied in the field of forging, can solve the problems of deceleration valve wear, corrosion, oxidation, etc., and achieve the effect of reducing sediment content and reducing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

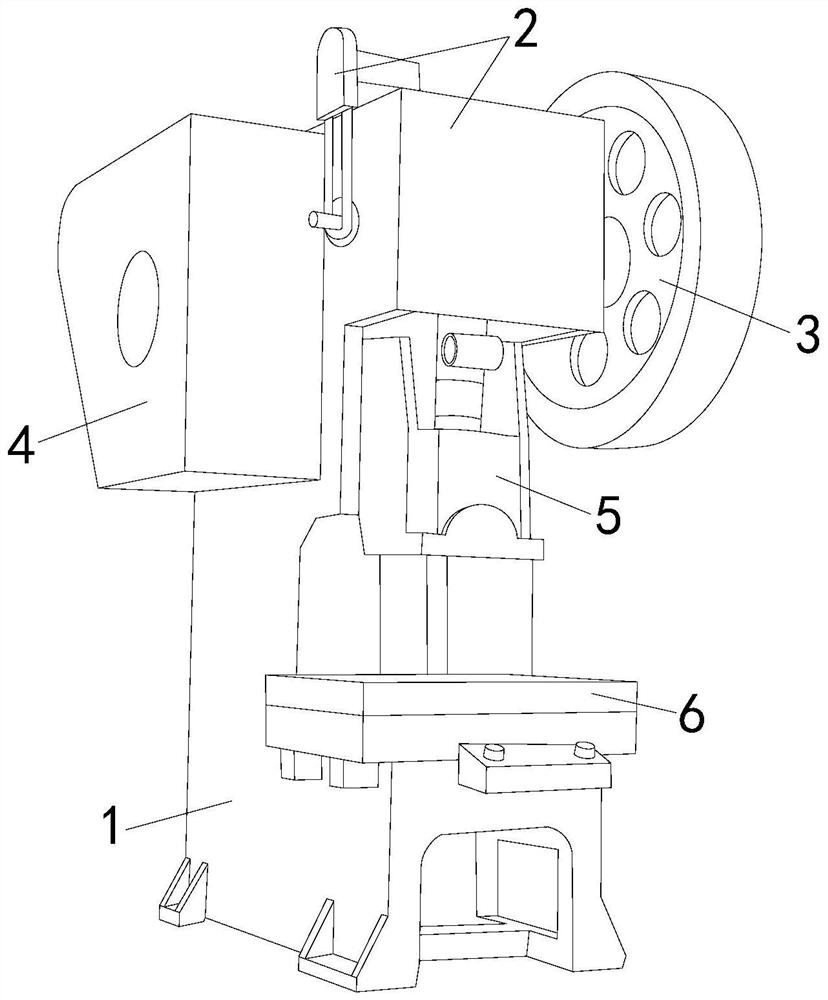

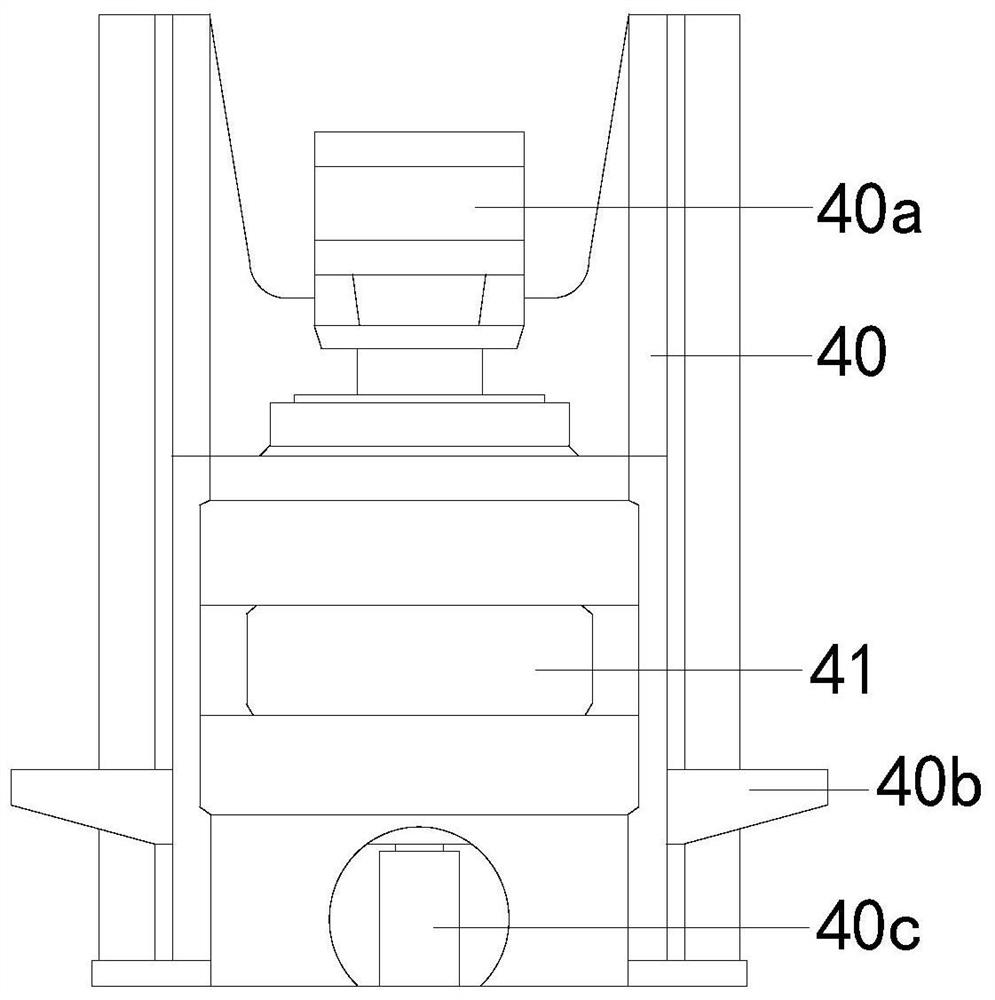

[0023]Seefigure 1 The present invention provides a horizontal hydraulic forging machine including: a body 1, a hydraulic device 2, a spindle 3, a hydraulic mechanism 4, a forging base 5, an forging table 6, and the body 1 is connected to a hydraulic pressure 2, hydraulic pressure The main shaft 3 is connected to the hydraulic mechanism 4 in the left and right ends, and the forging base 5 is provided at the bottom end of the hydraulic pressure 2 and the forging table 6 is provided below the forging position 5, while the middle portion of the body 1 is relative, the body 1 It is combined with a shaped irregular frame structure, which is used as the outer casing of the forging machine and the carrier connecting other components. It is also the load-bearing structure of the device, and the pressure from the tip of the device is divided into the ground to prevent structural factors. The pressure is supergens, and the hydraulic device 2 is a power conversion structure. The kinetic energy ...

Embodiment 2

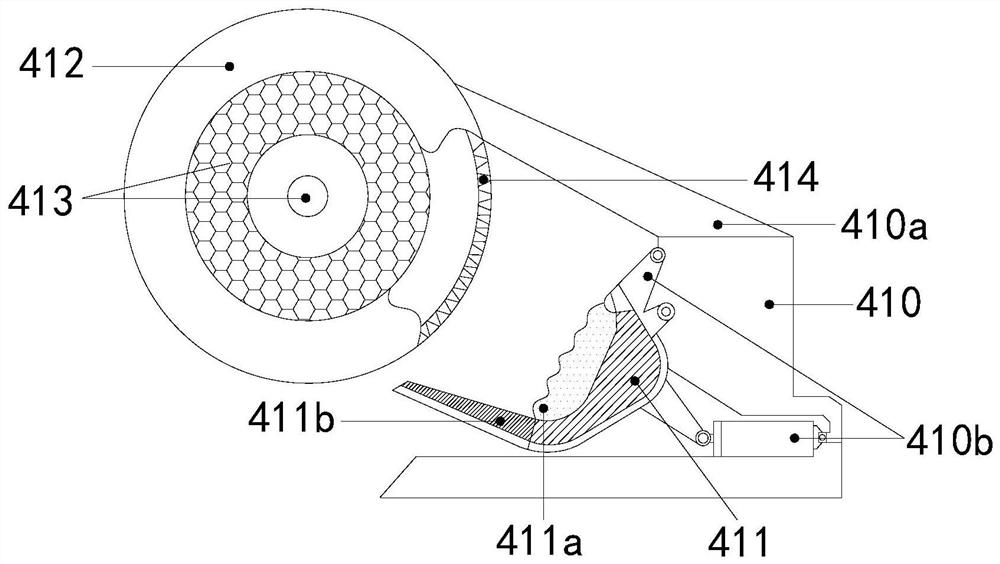

[0029]The second embodiment drawn in connection with the first embodiment, combinedimage 3 ,Figure 4 versusFigure 5The air reservoir 410 is connected to the filter oil-filled panel 411 and simultaneously connect with the screening roller 412, and the screening roller 412 is fitted to intercept the rotary axis 413 and the sides are provided with a screen 414. The cavity 4110 is distributed in the groove 4111, and the trough 4111 is connected to the output port 4113, respectively, and the surface of the cone 4131 is provided with a rotary plate 4131, and the rotary plate 4131 is uniformly distributed with a suction layer. 4132 is connected to it, in use, in order to avoid oil deposit obstruction structure, the oil is introduced into the screening roller 412, and the intercepting rotary axis 413 is flipped in the oil, and the surface of its surface is attached. 4132 Relying on the structural characteristics to attach the deposit in the oil to form a blockade, the remaining oil output f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com