Optical imaging aspheric lens mold core cleaning method and device

An aspheric lens, optical imaging technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problem that cleaning cleanliness and cleaning efficiency are not high enough, take a long time, and affect the quality of molding. and other problems, to achieve the effect of improving cleaning cleanliness and efficiency, high cleaning quality and efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

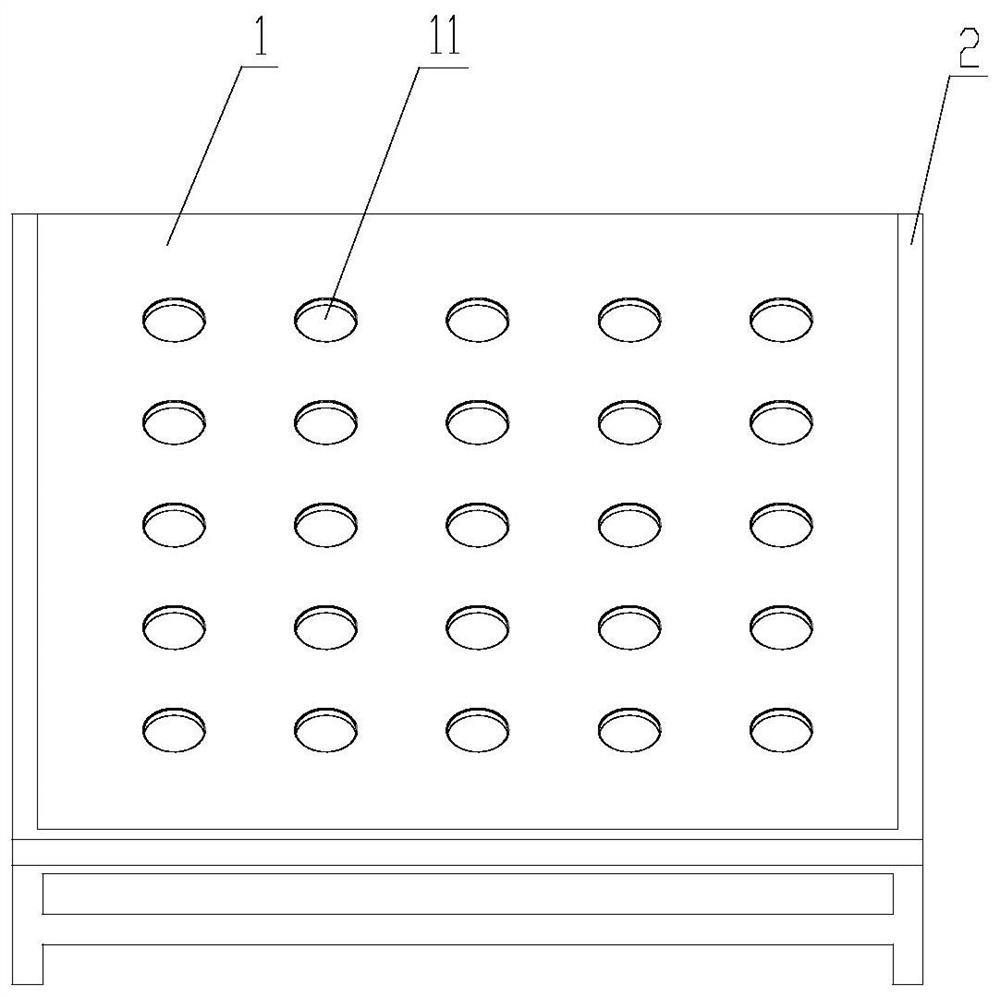

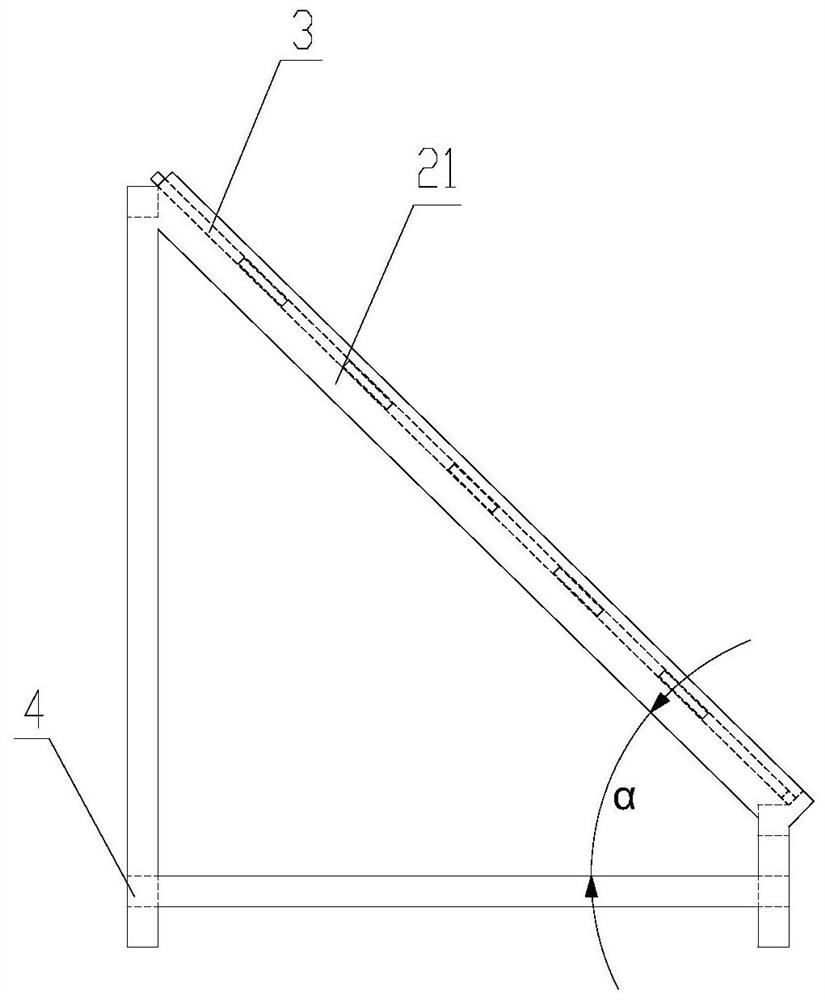

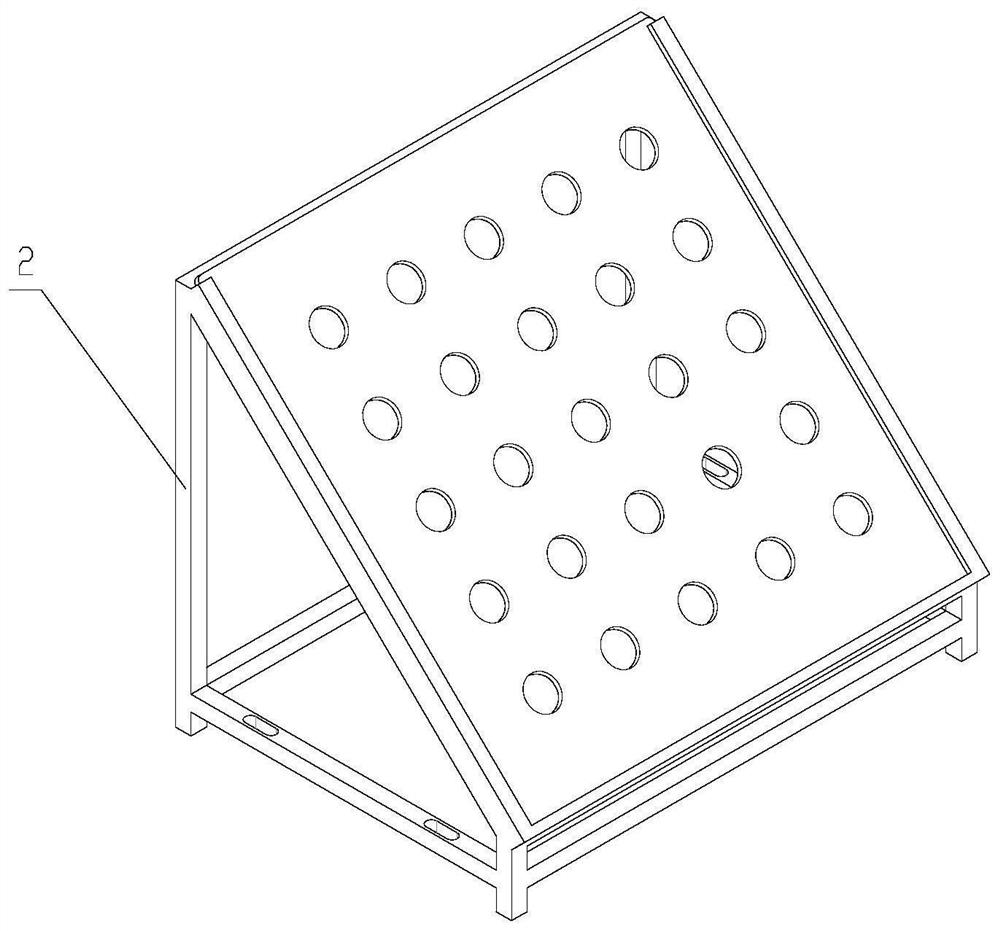

[0024] Such as Figure 1-3 As shown, the optical glass aspheric lens mold core cleaning device of the present invention includes a clamping device, a cleaning feeding rack, a multi-slot ultrasonic automatic cleaning machine and a control system. Among them, the clamping device includes a mold core clamping disc 1, a bracket 2 and a chute 3, and the length and width of the mold core clamping disc 1 can be determined according to the inner groove size of the multi-groove ultrasonic automatic cleaning machine; The chuck 1 is provided with a number of die core holes 11 for placing die cores. The die core holes 11 can be arranged at equal intervals. The inner diameter of the die core holes 11 is determined according to the size of the cylinder of the aspherical die core. The conventional size is φ3-50mm; the cross-section of the bracket 2 is a right triangle, and the inclined surface 21 maintains a certain inclination angle. Through multiple tests, the inclination angle α of the in...

Embodiment

[0035] Example: Taking a Φ33mm mold core as an example, since the mold core is a flat-convex surface, a small connection R (about 0.001mm) will be formed between the two surfaces, and there will be polishing paste and a small amount of oil stains, high-temperature glass bonding Substances, if the surface is just wiped with a cotton swab soaked in acetone, dirt will still remain inside the connection R. After coating, the dirt will be sandwiched between the mold core and the film layer, and it is easy to form a stripping film after high pressure and high temperature of pressing, reducing the service life of the film layer.

[0036] First, use cotton swabs to pre-clean the surface of the mold core with alcohol and acetone with a weight ratio of 1:35, put the mold core into the mold core chucking plate 1, and then guide it through the chute 3 and fix it on the bracket 2, and then place the whole The clamping device is fixed on the cleaning loading rack through the positioning gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com