Powder spreading system for polymetallic material 3D printing equipment

A 3D printing, multi-metal technology, applied in the field of metal 3D printing, can solve the problems of mechanical performance defects of metal products, unable to fully meet the actual preparation and use requirements, difficult distribution regulation and other problems, so as to reduce the molding cost and improve the compatibility. , the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

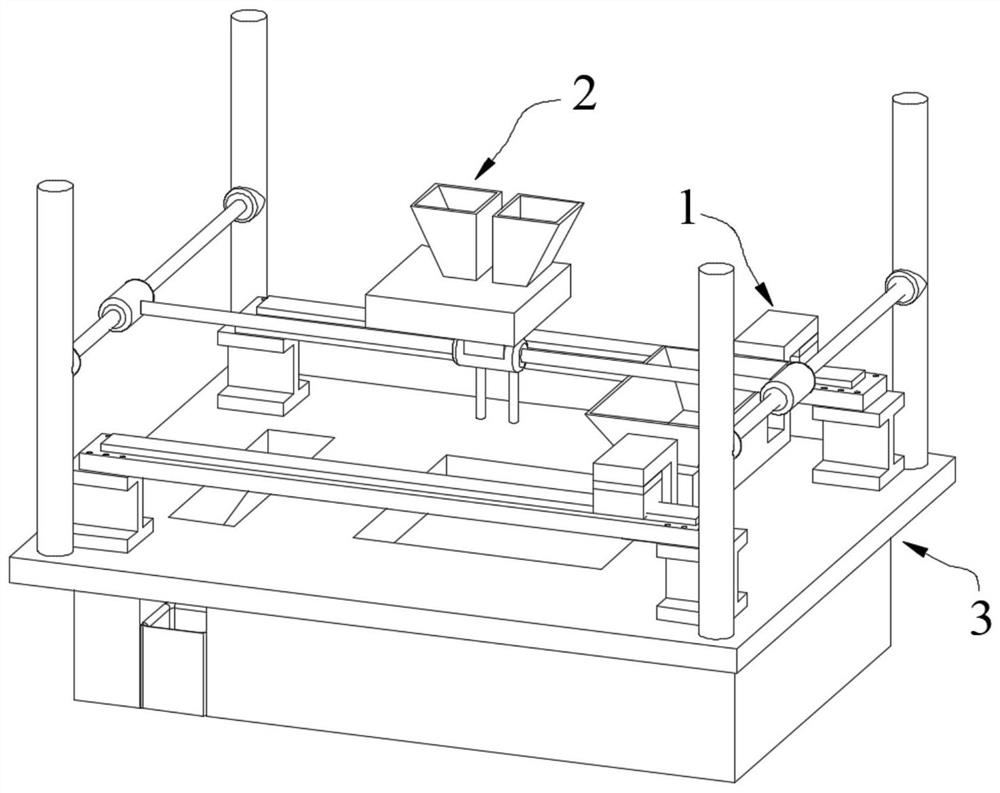

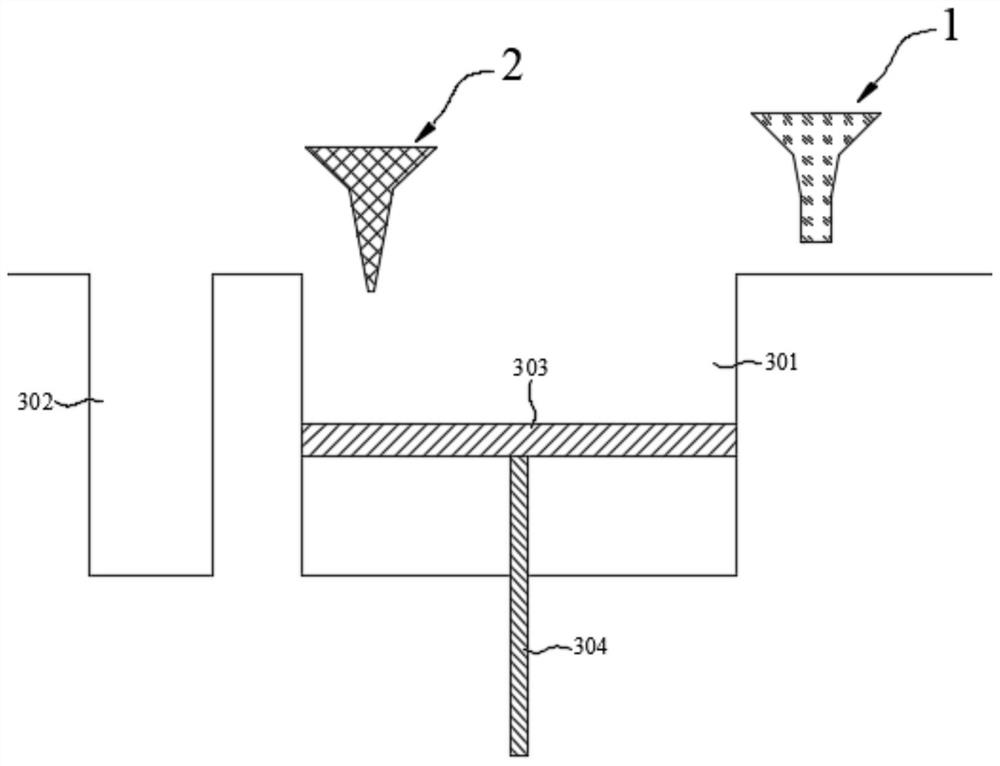

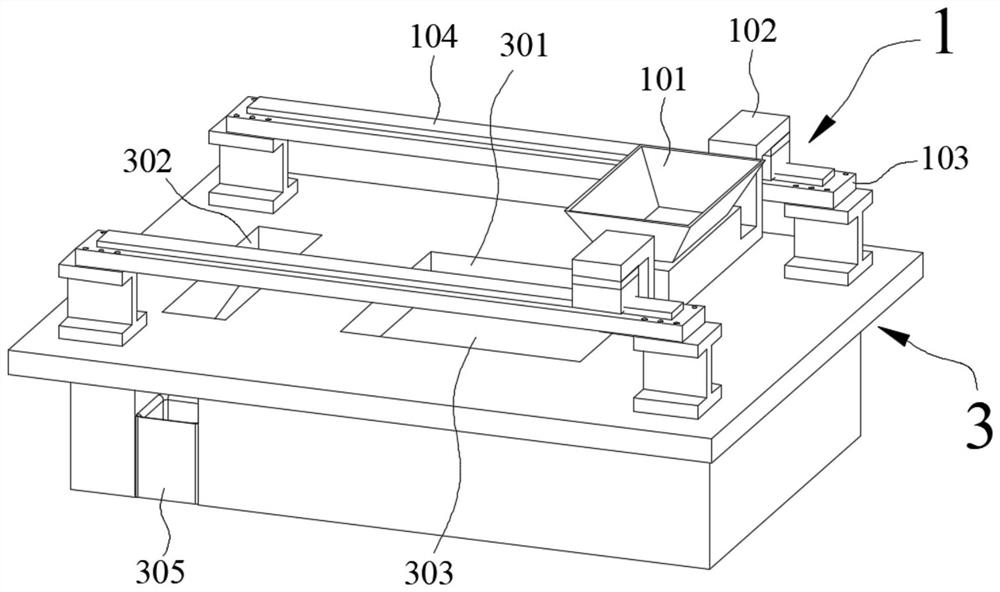

[0045] see Figure 1~6 , the powder laying system for multi-metal material 3D printing equipment in the preferred embodiment of the present invention includes a frame body 3 and a basic powder feeding assembly 1 and an auxiliary powder feeding assembly 2 corresponding to it. Among them, the basic powder feeding assembly 1 is used for laying of basic powder materials, and the auxiliary powder feeding assembly 2 is used for laying of enhanced powder materials.

[0046] Specifically, the frame body 3 in the preferred embodiment is as figure 2 As shown in , there is at least one powder spreading molding cylinder 301 on the top, which is used for powder laying and sintering molding, and guide rails 103 are respectively arranged on both sides of the powder spreading molding cylinder 301 . The two guide rails 103 are arranged in parallel, and preferably the direction of the two guide rails 103 is the longitudinal direction, and correspondingly, the horizontal direction perpendicula...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap