Cutting equipment for aluminum veneer and cutting process thereof

A technology of cutting equipment and aluminum veneer, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problems of low cutting efficiency, unstable operation, and uneven lines of the cutting end surface, and achieve high cutting size accuracy, Improved cutting efficiency and beautiful end face appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

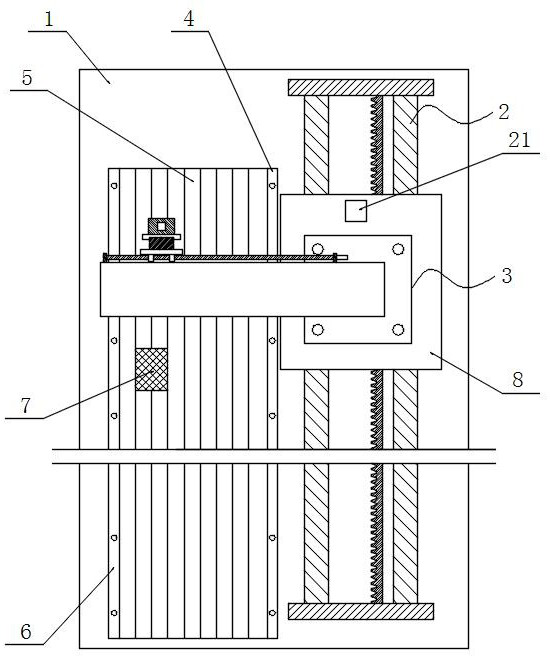

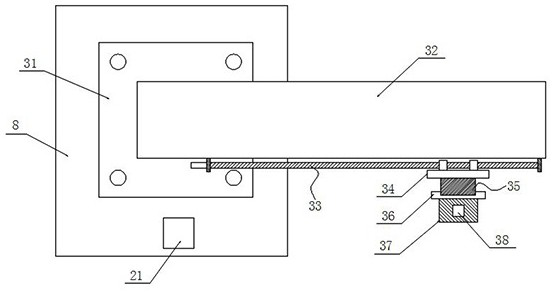

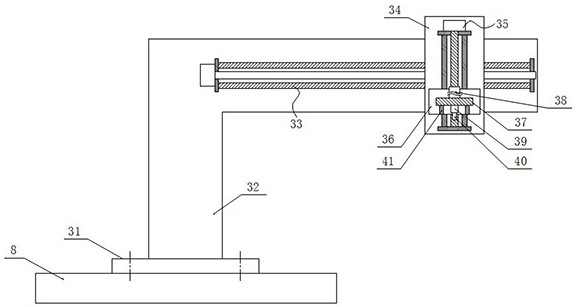

[0032] A kind of cutting equipment for aluminum veneer and its cutting process of the present invention, comprising machine tool 1, first moving mechanism 2, cutting device 3, first bottom plate 8, first limiting plate 4, second limiting plate 6, Positioning plate 5 and tire frame 7; Concrete structure such as Figure 1~7 As shown, the machine tool 1 is arranged horizontally, and the second limiting plate 6 and the first limiting plate 4 are arranged horizontally and sequentially on the left half of its upper surface from left to right. The second limiting plate 6 and the first limiting plate Limiting plates 4 are arranged horizontally and vertically, and a positioning plate 5 for positioning is also installed horizontally between the two. The positioning plate 5 is surrounded by the second limiting plate 6 and the first limiting plate 4. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com